Multi-tire packaging machine

A technology for packaging machines and tires, which is applied in the directions of packaging machines, packaging, transportation and packaging, etc. It can solve the problems of large space occupation, low height of packaging tires, and easy damage of tires, so as to save space and reduce the risk of damage , Reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

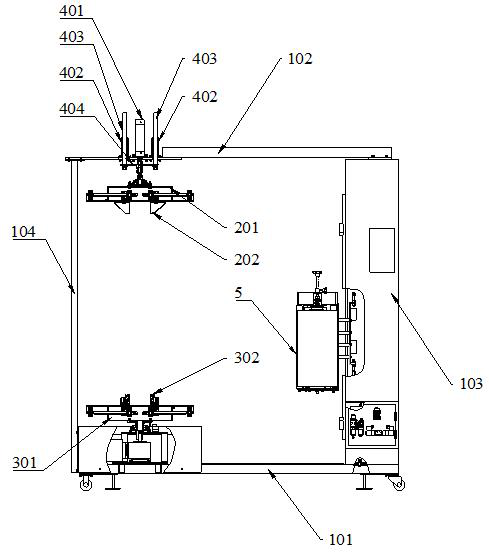

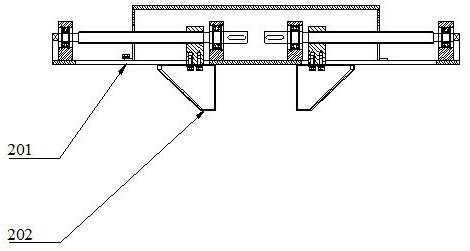

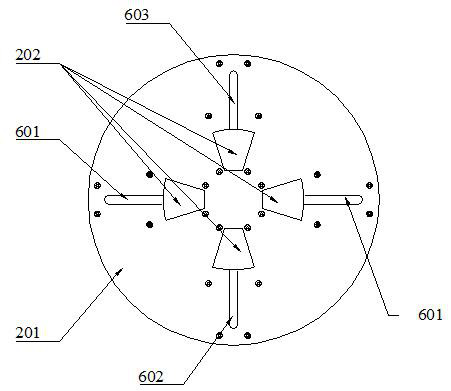

[0035] refer to figure 1 , the present embodiment provides a plurality of tire packing machines, including a frame, a first platen and a second platen, the first platen is set on the top of the frame, and the second platen is set on the bottom of the frame; The frame includes a base 101, a crossbeam 102, a column 103 and a connecting rod 104, the base 101 is arranged parallel to the crossbeam 102, and a vertical column 103 and a connecting rod 104 are vertically arranged between the base 101 and the crossbeam 102; the first platen passes through the first lifting mechanism Connected to the beam 102, the first platen includes a first plate body 201 and a plurality of first claws 202, the first lifting mechanism is connected to the top surface of the first plate body 201, and the first claws 202 are adjusted by the first sliding mechanism It is arranged on the bottom surface of the first disc body 201, and the distance from each first claw 202 to the center of the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com