Output detection device and method for optical cement coating

A technology of output detection and optical glue, which is applied in the field of output detection devices for optical glue coatings, can solve the problems of large limitations of detection devices, waste of paint properties, and paint seepage, so as to avoid paint deterioration and waste, diversify functions, and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

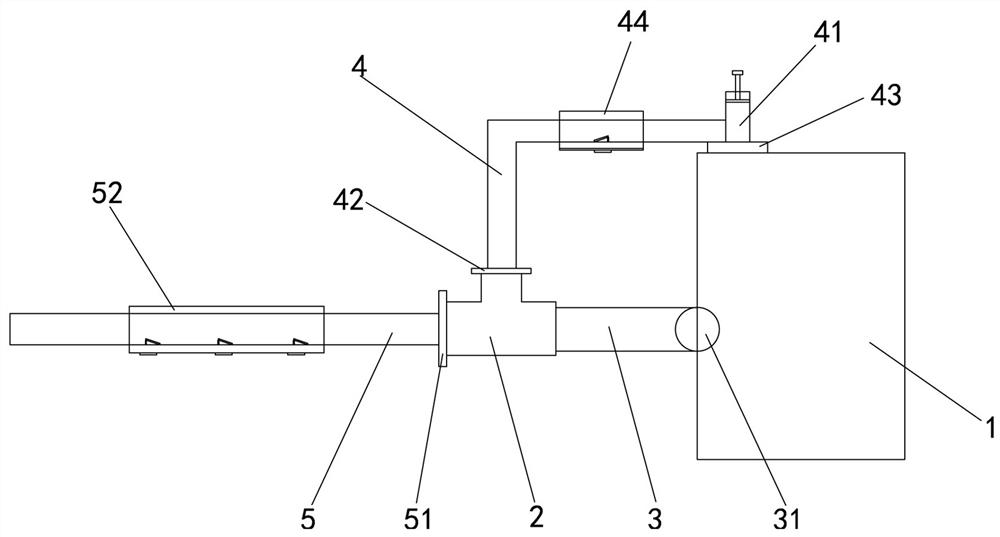

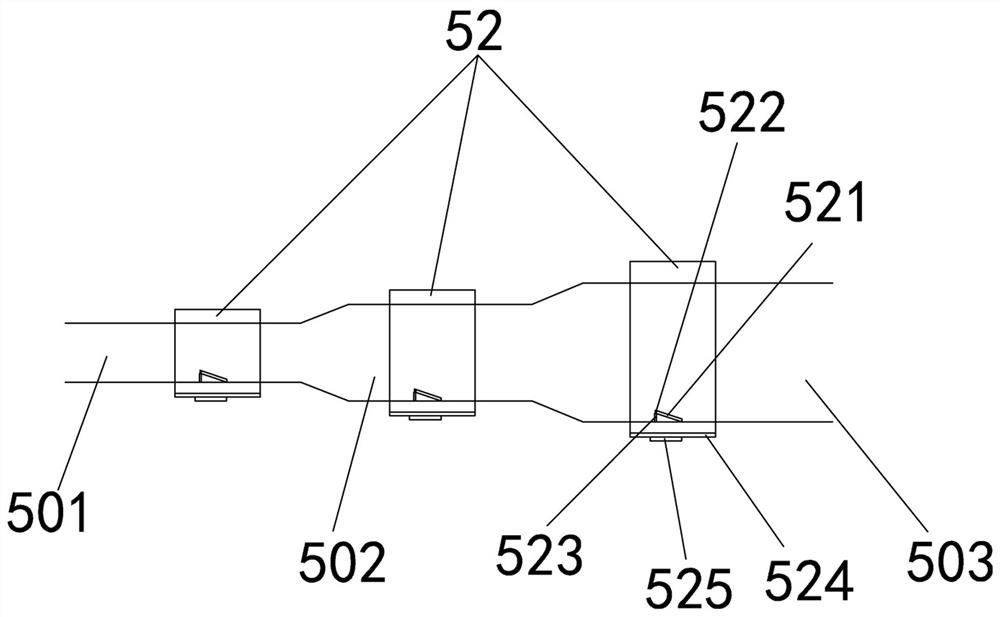

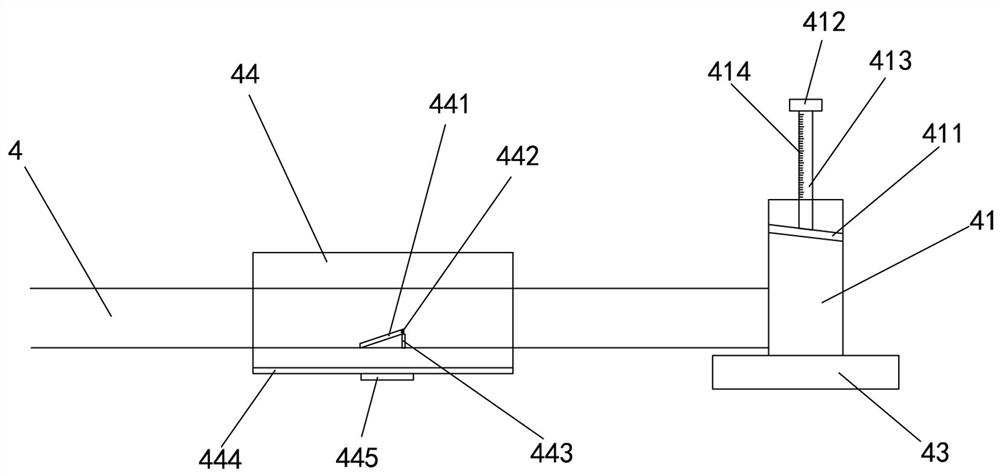

[0035] Embodiment one: if Figures 1 to 3 As shown, it is only one of the embodiments of the present invention, a kind of output detection device of optical adhesive paint, comprising a paint tank 1 and a three-way valve 2, and the three connection ports of the three-way valve 2 are respectively connected with discharge Pipe 3, return pipe 4 and output pipe 5, the end of the discharge pipe 3 away from the three-way valve 2 communicates with the paint tank 1 through the discharge pump 31, and the return pipe 4 is far away from the three-way valve 2. One end of the through valve 2 communicates with the paint tank 1 through the feed back tube 41, a first valve 42 is arranged between the feed back pipe 4 and the three-way valve 2, and the feed back tube 41 is connected to the paint tank 1. A second valve 43 is provided between the tanks 1, a return detection part 44 is provided on the return pipe 4, a return display screen 445 is provided on the return detection part 44, and the o...

Embodiment 2

[0056] Embodiment two, still as Figures 1 to 3 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in the output detection device of the optical adhesive paint of the present invention, the first plate 411 is set at an inclination. Generally speaking, the first plate 411 The end of the plate 411 close to the return pipe 4 is inclined upward, so that when the paint passing through the return pipe 4 flows into the return barrel 41 , it can flow to the bottom of the first plate 411 .

[0057] Of course, the return cylinder 41 is preferably a regular polygonal straight cylinder or a cylinder. When the flow rate of the optical adhesive paint flowing into the return cylinder 41 is constant, the rising speed of the connecting rod 413 is also constant, and the first plate 411 is just filled. The range of the return barrel 41 and the cross section prevents the optical adhesive paint from flowing to the top of the first plate 411 .

[00...

Embodiment 3

[0060] Embodiment three, such as Figure 4 As shown, the present invention also provides a detection method of an output detection device of an optical glue coating in all the above-mentioned embodiments, comprising the following steps:

[0061] S1: Fix the paint tank and the three-way valve, and connect the discharge pipe, return pipe and output pipe to the three connection ports of the three-way valve;

[0062] S2: Close the third valve and the second valve, open the first valve and the discharge pump, so that the optical glue paint in the paint tank enters the return pipe through the discharge pipe and the three-way valve;

[0063] S3: Determine whether the display value of the return display screen at the return pipe remains unchanged and the reading value of the return scale scale becomes larger and the speed is stable; if so, the display value of the return display screen and the reading value of the return scale scale change Acquire the viscosity value of the optical g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com