Injection-discharge oil device for lubrication of rotor bearing of high capacity motor

A technology for motor rotor and bearing lubrication, applied in the direction of electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as trouble, early wear and damage, grease waste, bearing lubrication failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

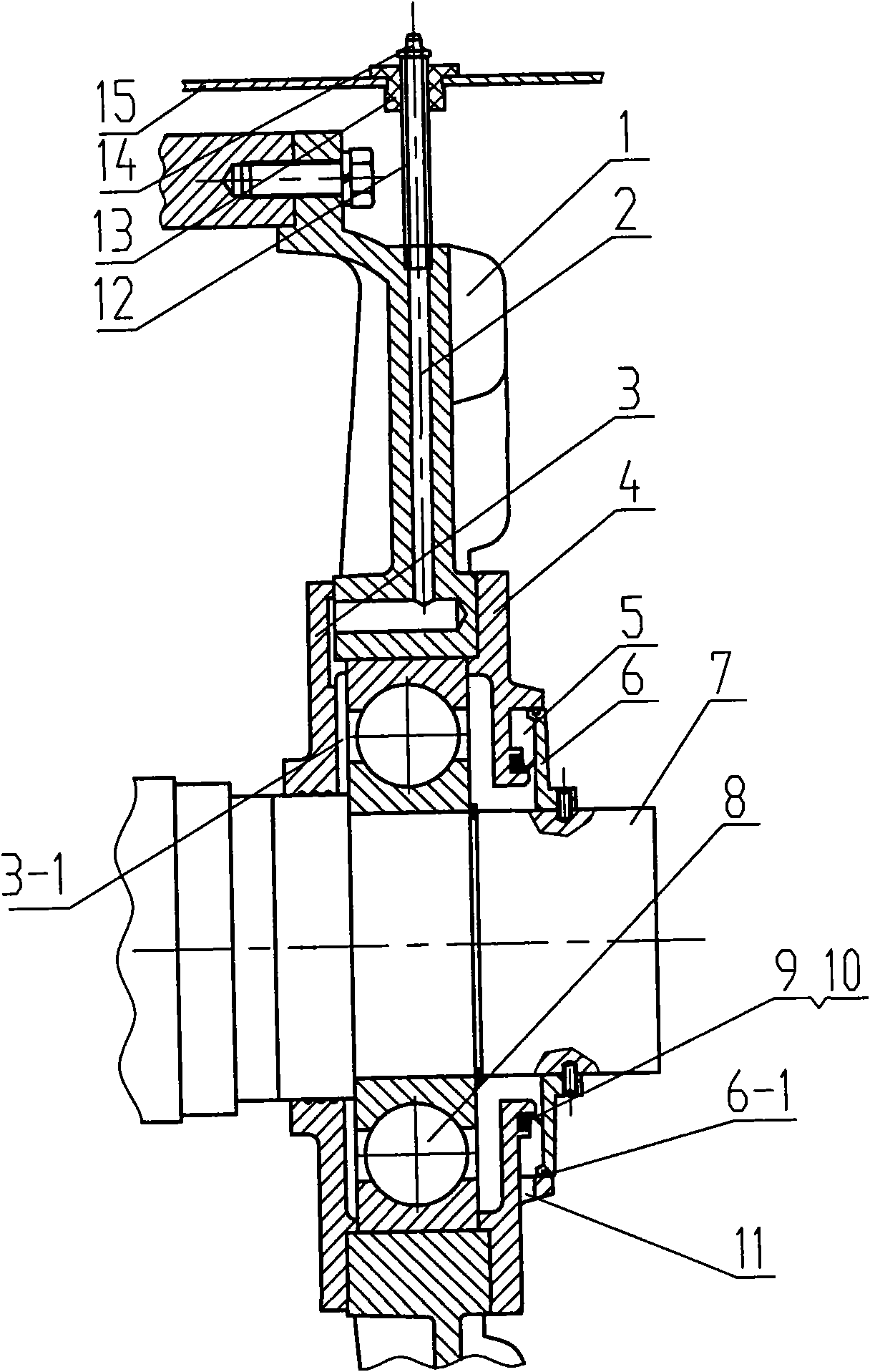

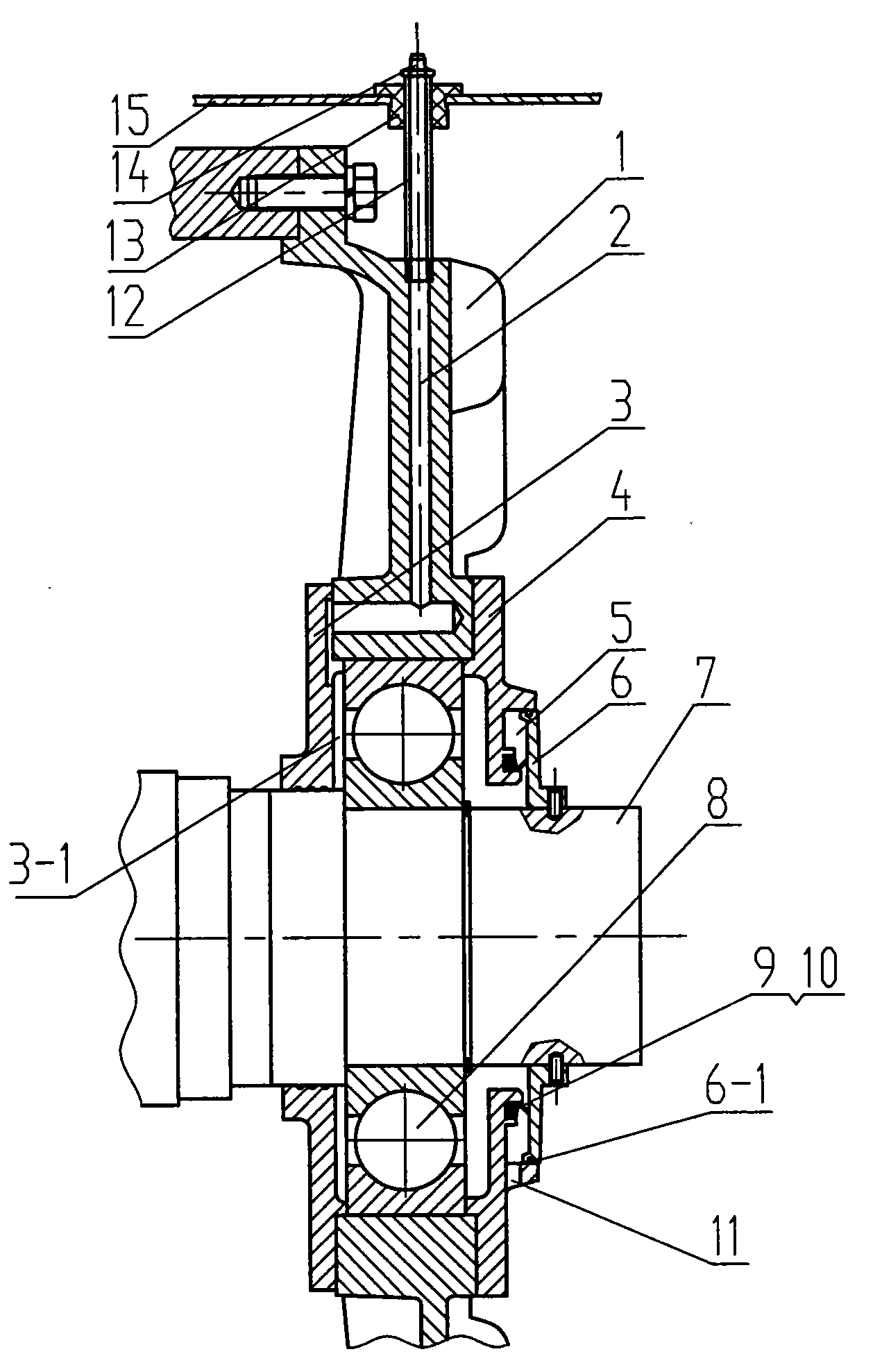

[0010] see figure 1 , the large-capacity motor rotor bearing lubricating oil injection and draining device of the present invention comprises a motor end cover 1, a bearing inner cover 3, a bearing outer cover 4, a motor shaft 7 and a motor bearing 8, wherein, on the top of the motor end cover 1 is provided Oil injection passage hole 2, the top of oil injection passage hole 2 is equipped with oil injection pipe 12 and oil injection nozzle 14, and oil injection pipe 12 is fixedly connected with motor fan cover 15 by flange sleeve 13. An annular oil groove 3-1 is provided on the bearing pressing end surface of the bearing inner cover 3, and the annular oil groove 3-1 communicates with the oil injection channel hole 2 on the top of the motor end cover 1 and the bearing 8, and constitutes the oil injection channel of the motor bearing 8. The outer end surface of the bearing cover 4 is provided with an annular opening oil discharge groove 5 that can communicate with the bearing 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com