Blocky quicklime doped powder lime mortar for repairing ancient buildings and preparation method ofblocky quicklime doped powder lime mortar

A technology of quicklime and fossilized lime, applied in the field of ancient building repair materials, can solve the problems of not reducing performance, safety hazards, resource waste, etc., and achieve the effect of avoiding deterioration and waste, avoiding safety hazards, and increasing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In order to study the rationality of different slaking methods, the present invention first adopts the slaked lime produced by two slaking methods to compare the macroscopic appearance of the sample. The water-cement ratio of the two methods is difficult to unify. The mortar adopts a uniform fluidity, and the detailed information of the samples is shown in Table 1.

[0043] Table 1 Specimen Details

[0044]

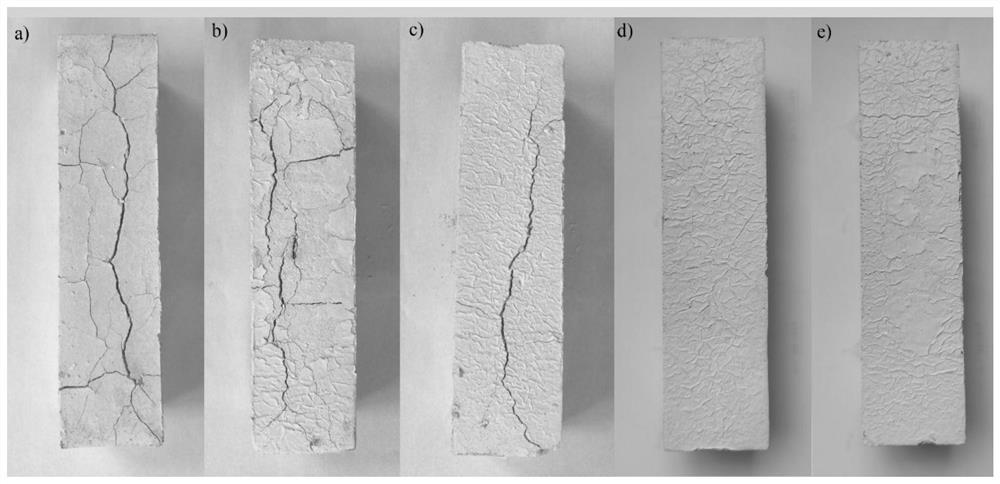

[0045] figure 1 The macroscopic morphology of the samples after sample preparation and curing by different dusting methods. It can be seen from the figure that CT-7, CT-15, and CT-28 have relatively serious cracks, which shows that there are still many chronic ash after 28 days of lime stacking in the traditional method, and the reaction will continue to cause swelling and cracking after sample preparation. After 56 days, this cracking phenomenon will disappear, and the construction period will obviously be delayed during construction. To shorten the construct...

Embodiment 2

[0047] The detailed ratio of raw materials when table 2 is stuffy;

[0048] Table 3 detailed proportioning of raw materials during sample preparation;

[0049] Table 4 Mortar sample 60-day density, open porosity and water absorption;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com