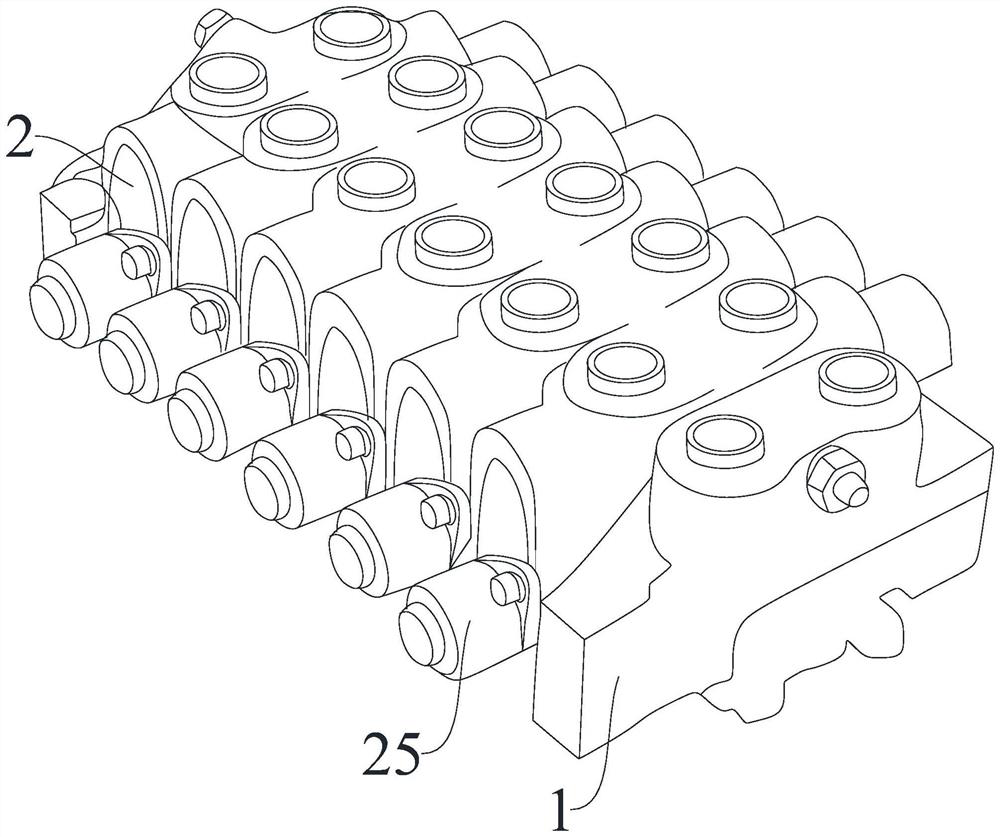

Angle-adjustable multi-way reversing valve

A multi-way reversing valve and adjustable technology, applied in the field of sealing control valves, can solve the problems of high installation position requirements of multi-way reversing valve, fixed angle of multi-way reversing valve, complicated control operation, etc., to avoid internal Oil leakage, various installation methods and positions, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

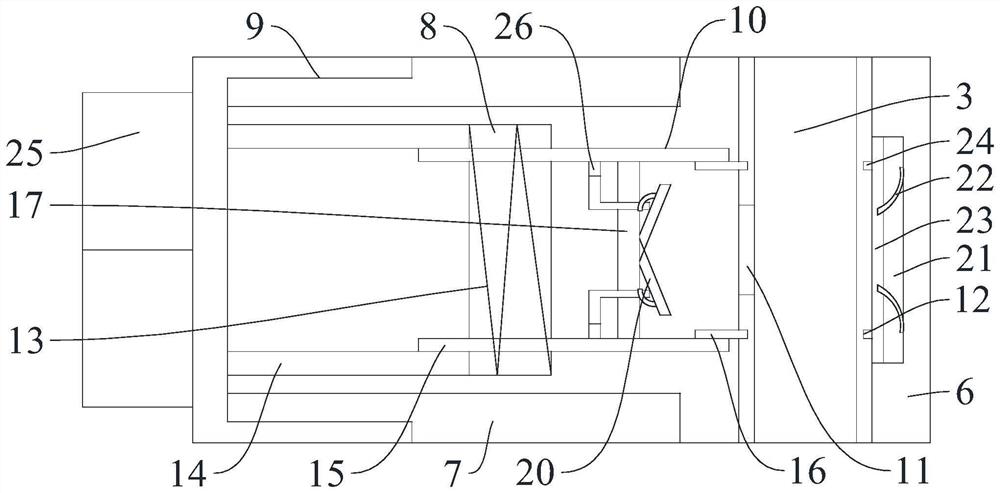

[0042] Embodiment 1: When connecting, it is only necessary to disassemble the internal thread assembly sealing cover 25. At this time, the anti-return plate 20 in the internal linkage self-closing frame is turned outward, and there is a non-return plate on the inner wall of the internal installation frame 18. 20 cooperates with the limit closing frame of the integrated structure, the non-return plate 20 is closed, and the outer opening of the external oil delivery conduit 7 is controlled to be closed. The internally threaded oil guide pipe extrudes the external extruding frame 14, and the external extruding frame 14 will synchronously control the inward extrusion of the arc-shaped limit tooth frame 16, and synchronously control the inward turning of the check plate 20, so that the outer oil delivery conduit 7 The opening remains open.

Embodiment 2

[0043] Embodiment 2: as Figure 4 As shown, an arc-shaped sealing closing plate can be fixed on the inner side of the arc-shaped limit tooth frame 16 through an inner connecting rod, so that the internal linkage self-closing frame is not needed, and the arc-shaped discharge can also be located inside the inner material guide tube 3. The openings on both sides of the port 11 are movable and equipped with a sideways flip closing plate matched with an arc-shaped sealing closing plate. When the arc-shaped sealing closing plate is pulled outward, it can automatically close the flow inside the internal material guide pipe 3, so that it can be The on-off circuit of the internal material guide pipe 3 is controlled as required.

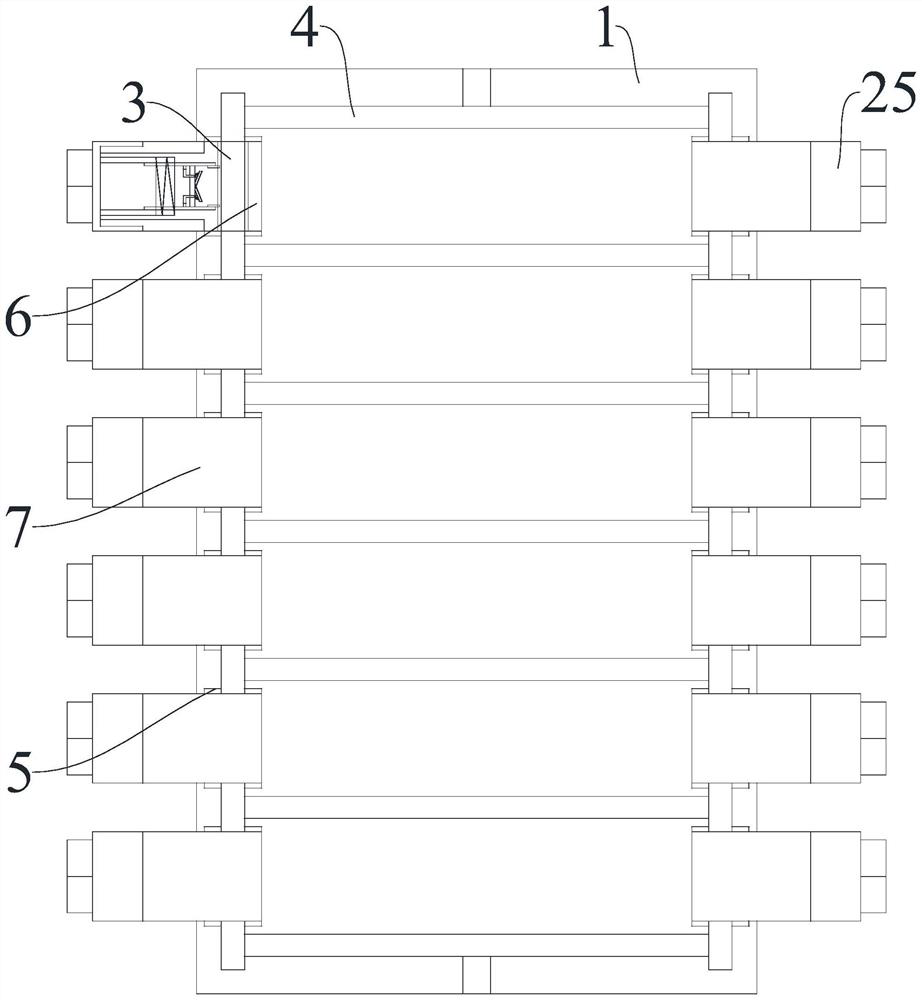

[0044] An angle-adjustable multi-way reversing valve of the present invention is provided with a lateral bottom assembly groove 2 with a built-in external oil delivery adjustment device on both sides of the lower surface of the main valve body 1, through which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com