Novel drilling machine for machining and using method thereof

A new type of mechanical processing technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of drilling machine processing efficiency and accuracy, complex adjustment, etc., to avoid force displacement and reduce resistance , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

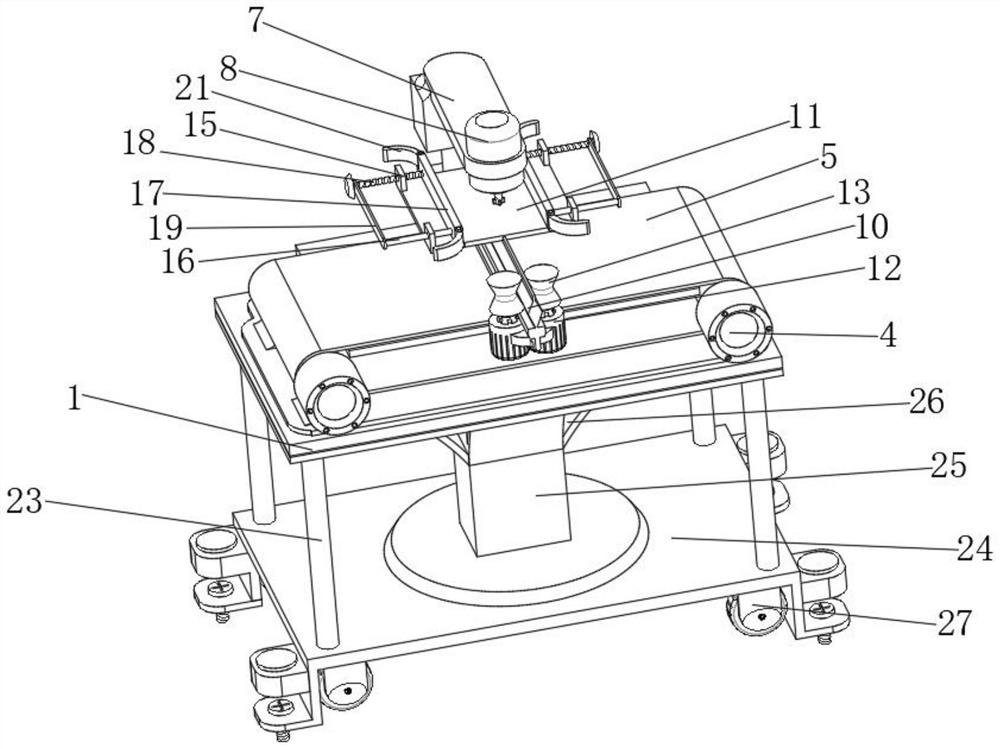

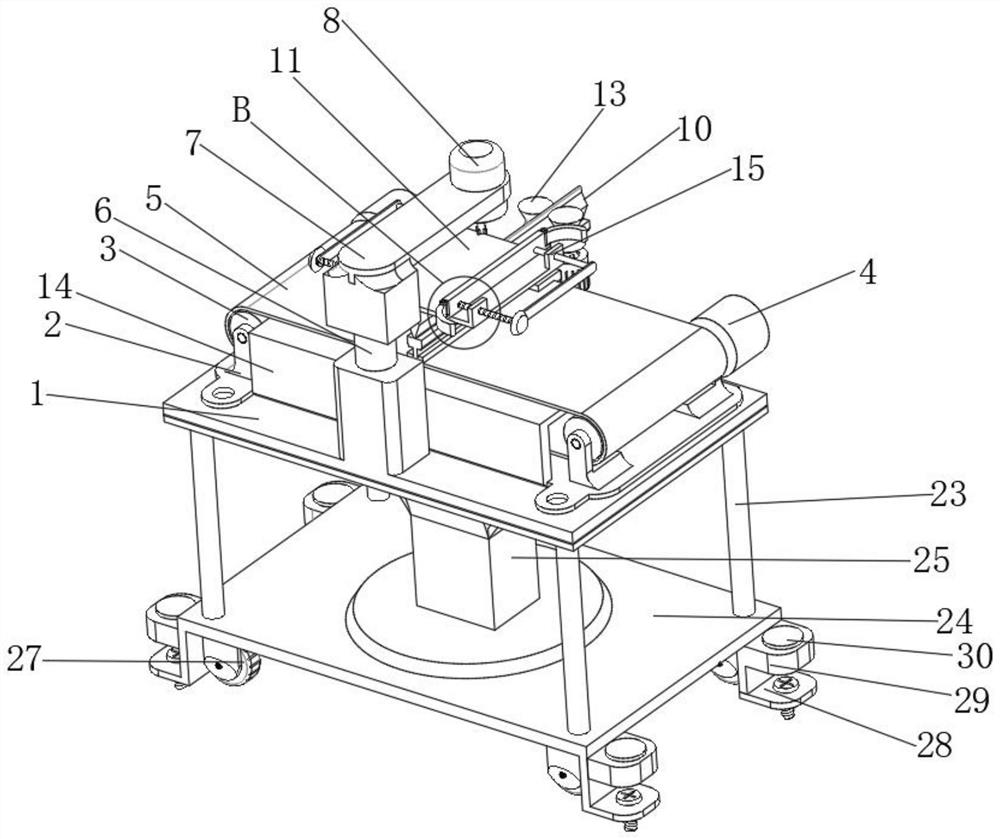

[0034] see Figure 1-4 , the present invention provides a technical solution: a new type of drilling machine for machining and a method of using the same, comprising a table board 1, the upper surface of the table board 1 is equipped with a hydraulic rod 6, and the top of the hydraulic rod 6 is equipped with a bracket 7, The inner side of the bracket 7 is equipped with a drilling rig 8. The expansion and contraction of the hydraulic rod 6 can drive the bracket 7 to adjust the height, and thus drive the drilling rig 8 to adjust the height. Through the operation of the drilling rig 8, the machine can be drilled. The four corners of the upper surface of the table board 1 are equipped with a support frame 2, which can provide stable support for the support frame 2 through the table board 1. The inner side of the support frame 2 is rotatably connected with a roller 3, and the rotation of the roller 3 can be provided by the support frame 2. Support and fix the rotation track of the ...

Embodiment 2

[0036] see image 3 and 6 , the four corners of the upper surface of the placing plate 11 are equipped with support plates 15, which can provide stable support for the structure of the support plate 15 through the placement plate 11. There is a splint 17, and the other end of the limit rod 16 is equipped with a limit plate 19. By sliding the limit rod 16 on the inner side of the support plate 15, the movement track of the splint 17 can be fixed, and the structure of the limit plate 19 can avoid the limit. The position rod 16 is separated from the support plate 15, which further restricts the movement range of the clamp plate 17. A screw 18 is rotatably connected between the clamp plate 17 and the limit plate 19, and the outer surface of the support plate 15 is provided with screw holes. The hole is rotatably connected with the screw 18. The purpose of this design is to enable the rotation of the screw 18 to cooperate with the screw hole, so that the screw 18 can move along th...

Embodiment 3

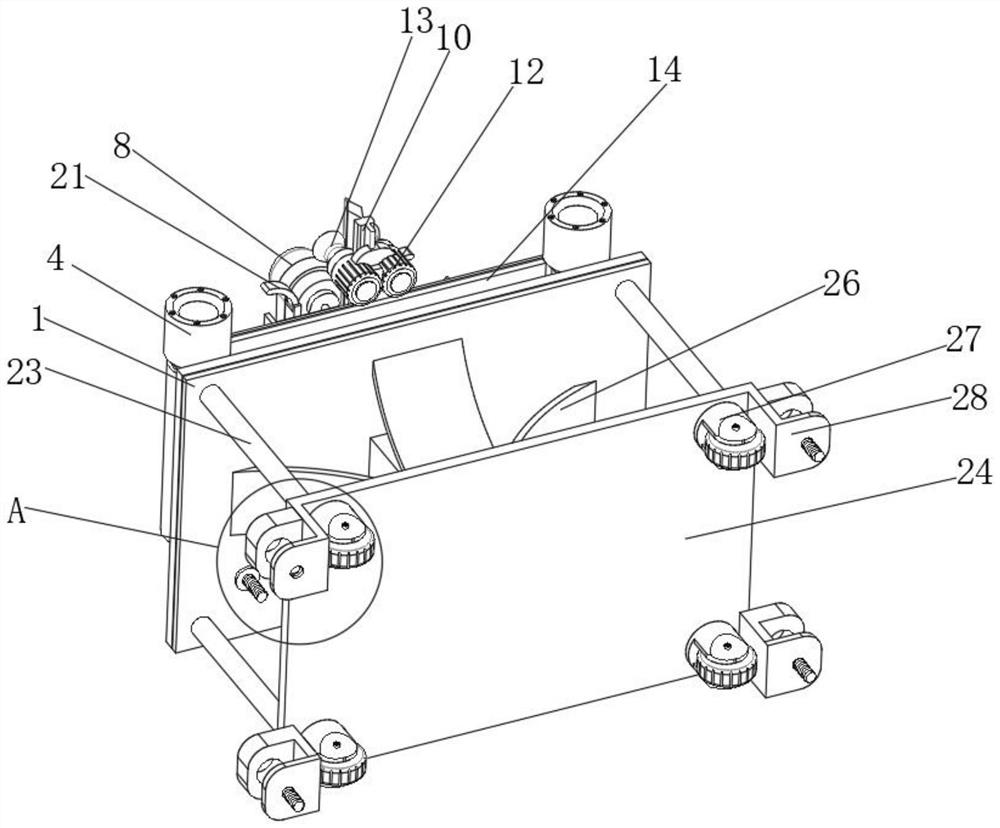

[0038] see figure 2 , 3 And 5, the four corner positions of the lower surface of the table board 1 are all equipped with table legs 23, the bottom end of the table legs 23 is equipped with a bottom plate 24, and between the bottom plate 24 and the table board 1 is equipped with a pillar 25, through the pillar 25 and the table leg 23, The connection function between the table board 1 and the bottom plate 24 can be realized, and a reinforcement plate 26 is installed between the pillar 25 and the table board 1. The reinforcement plate 26 can make the structure between the pillar 25 and the table board 1 more stable, and then realize the stability of the table. The stable support function of the plate 1, the four corners of the bottom surface of the bottom plate 24 are connected with a universal wheel 27, and the rotation of the universal wheel 27 can reduce the resistance to the movement of the bottom plate 24. The frame 28, the lower surface of the fixing frame 28 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com