Steel wire coil placing rack

A technology for steel wire coils and racks, which is applied to display devices, external frames, packaging, etc., and can solve problems such as worker injuries, steel wire coils that are heavy, easy to roll over and fall over, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

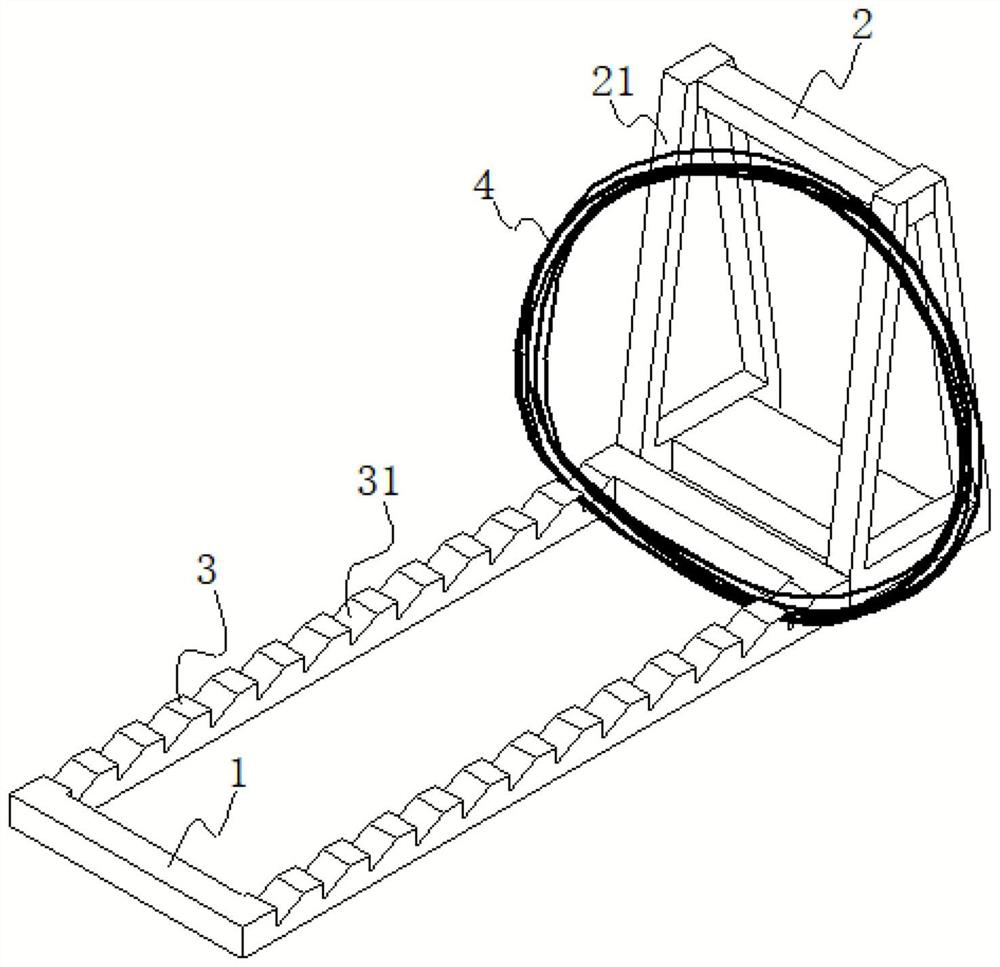

[0019] Example 1 is basically as attached figure 1 The specific implementation process is as follows:

[0020] The steel wire coil placement rack includes a horizontal frame body 1 placed on the ground and a vertical support frame 2. The support frame 2 is fixedly connected with the horizontal frame body 1. The horizontal frame body 1 is a rectangular frame, and the placement bar 3 is located in the length direction of the rectangular frame. On the two sides, the upper surface of the placing bar 3 is provided with a chute 31 for preventing the horizontal sliding of the wire coil, and the chute 31 includes a vertical surface for preventing the horizontal sliding of the wire coil 4; The diameter of the steel wire of coil 4 is 2 to 5 times. Between the two placing bars 3 , that is, inside the frame of the rectangular frame, a standing area for the wire coil 4 is formed; Among them, in order to improve the overall stability of the horizontal frame body 1, the four sides of the r...

Embodiment 2

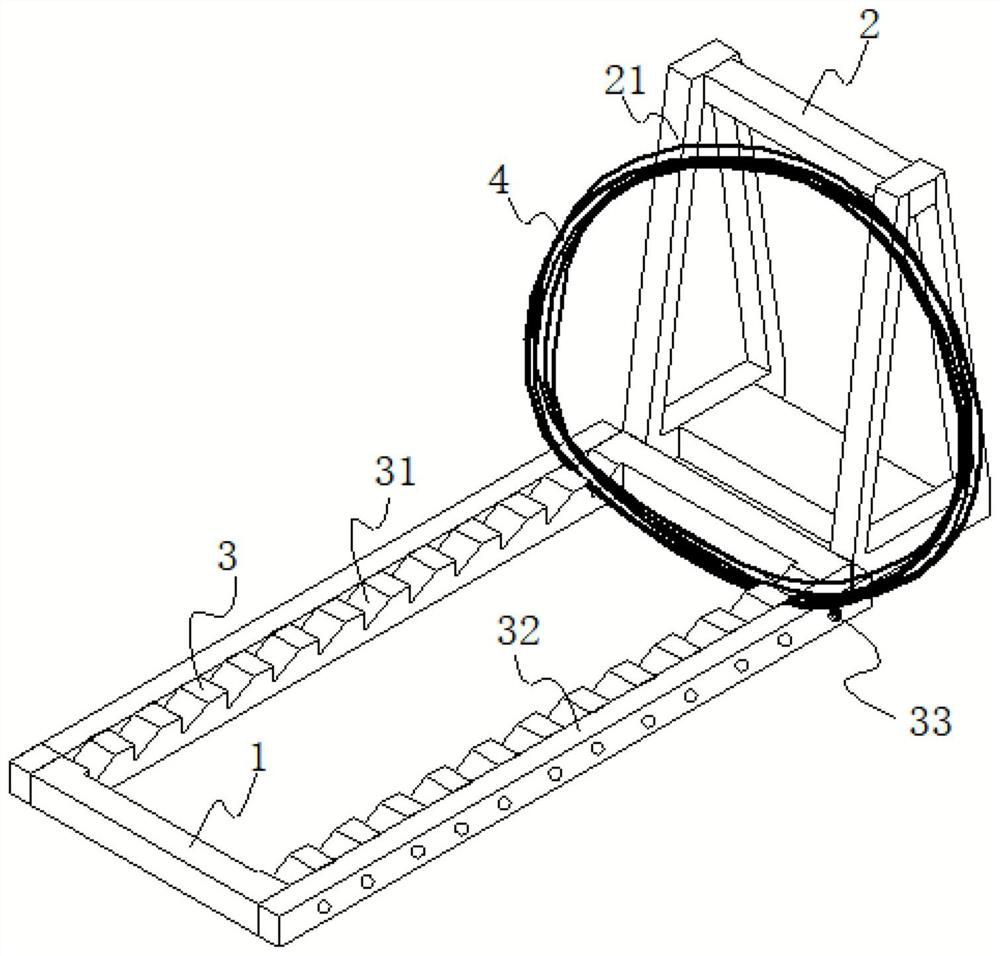

[0022] Example 2 is basically as attached figure 2 The specific implementation process is as follows:

[0023] The steel wire coil placement rack includes a horizontal frame body 1 placed on the ground and a vertical support frame 2. The support frame 2 is fixedly connected with the horizontal frame body 1. The horizontal frame body 1 is a rectangular frame, and the placement bar 3 is located in the length direction of the rectangular frame. On the two sides, the upper surface of the placing bar 3 is provided with a chute 31 for preventing the horizontal sliding of the wire coil, and the chute 31 includes a vertical surface for preventing the horizontal sliding of the wire coil 4; The diameter of the steel wire of coil 4 is 2 to 5 times. Between the two placing bars 3 , that is, inside the frame of the rectangular frame, a standing area for the wire coil 4 is formed;

[0024] The upper surface of the placing bar 3 is divided into two areas along the length direction, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com