Water storage device for industrial production

A water storage tank and water pump technology, which is applied to the configuration of drinking water installations, water supply installations, and water supply pools, etc., can solve the problems of insufficient resource movement and inconvenient cleaning, so as to improve the cleaning effect, simplify the cleaning process, and ensure the cleaning quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

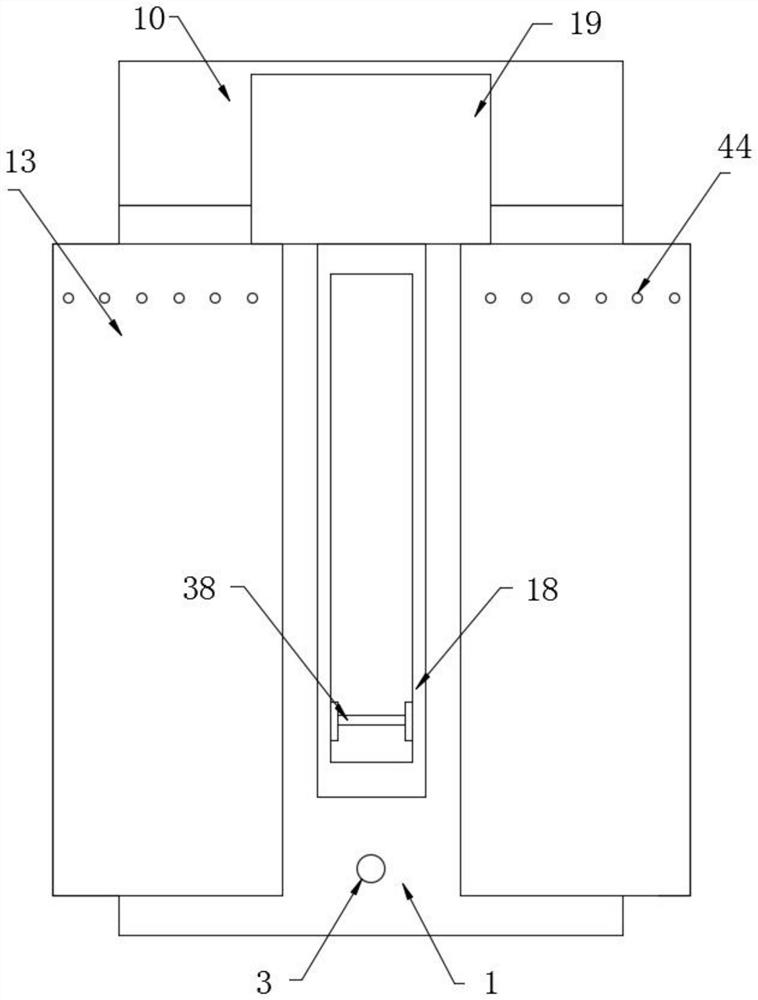

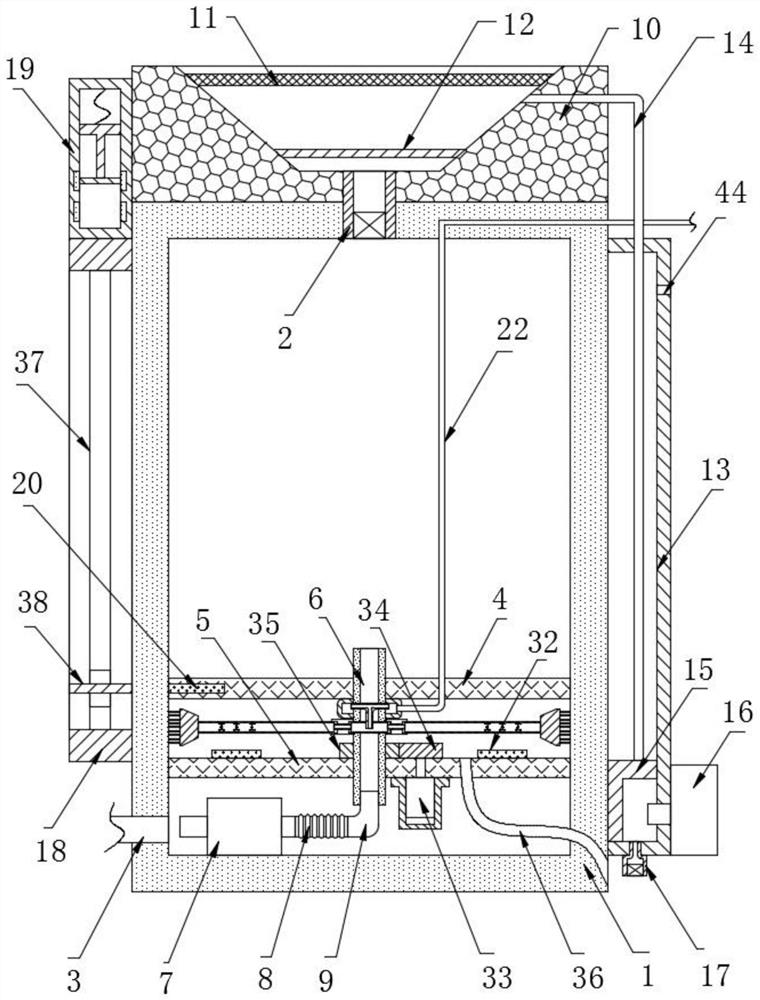

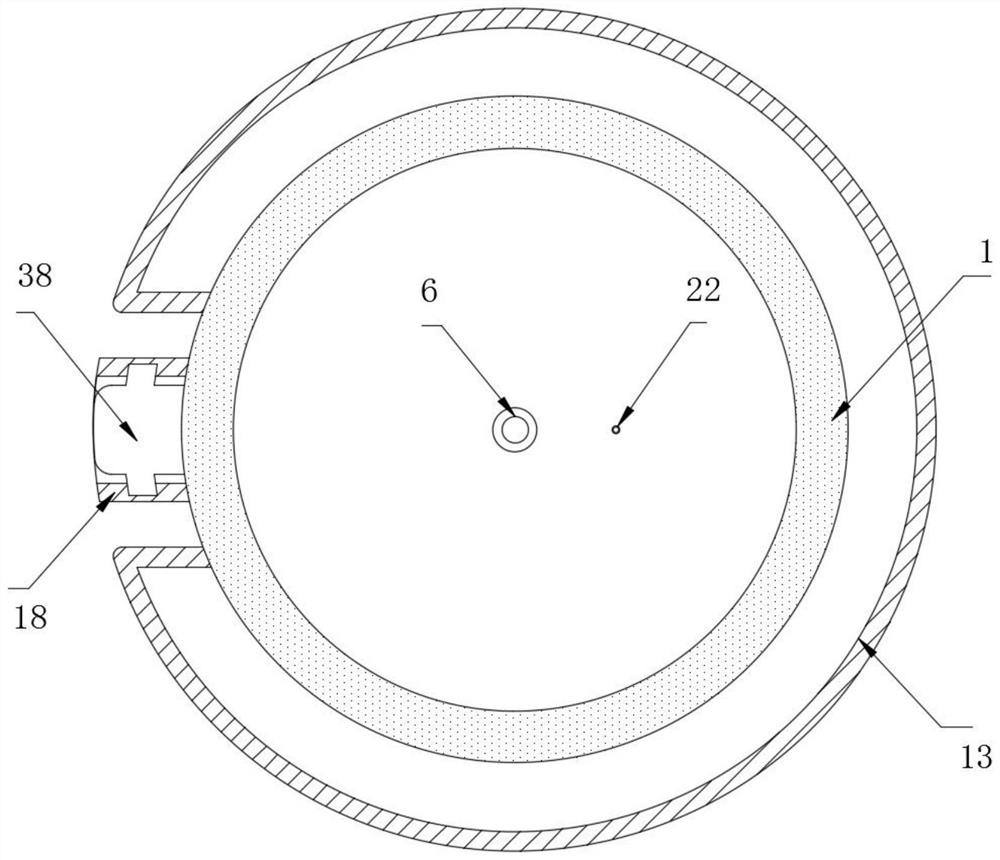

[0030] refer to figure 1 , figure 2 and Figure 7 , a water storage device for industrial production, comprising a water storage tank 1, the upper end of the water storage tank 1 is inserted with a water injection pipe 2, the lower side wall of the water storage tank 1 is inserted with a drainage pipe 3, and the inner wall of the water storage tank 1 The upper clapboard 4 and the lower clapboard 5 are sealed and slidingly connected. The inner bottom of the water storage tank 1 is fixed with a water pump 7. The port of the water pump 7 is connected with a transfer pipe 9 through a telescopic pipe 8. The telescopic pipe 8 is a corrugated pipe and can be extended. Thereby, the transfer of the upper clapboard 4 and the lower clapboard 5 is matched, and the end of the transfer pipe 9 is sealed and rotatably connected with the transition pipe 6. 4 and the lower partition plate 5 are connected by the transition pipe 6 to form a whole, the side wall of the transition pipe 6 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com