Metal material melting traction equipment for improving comprehensive performance of copper plate

A comprehensive performance and metal material technology, applied in the field of metal material melting traction equipment, can solve problems such as potential safety hazards, instability in the traction process, fluctuations in liquid metal materials, etc., and achieve the effects of improving power support, improving containment effect, and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

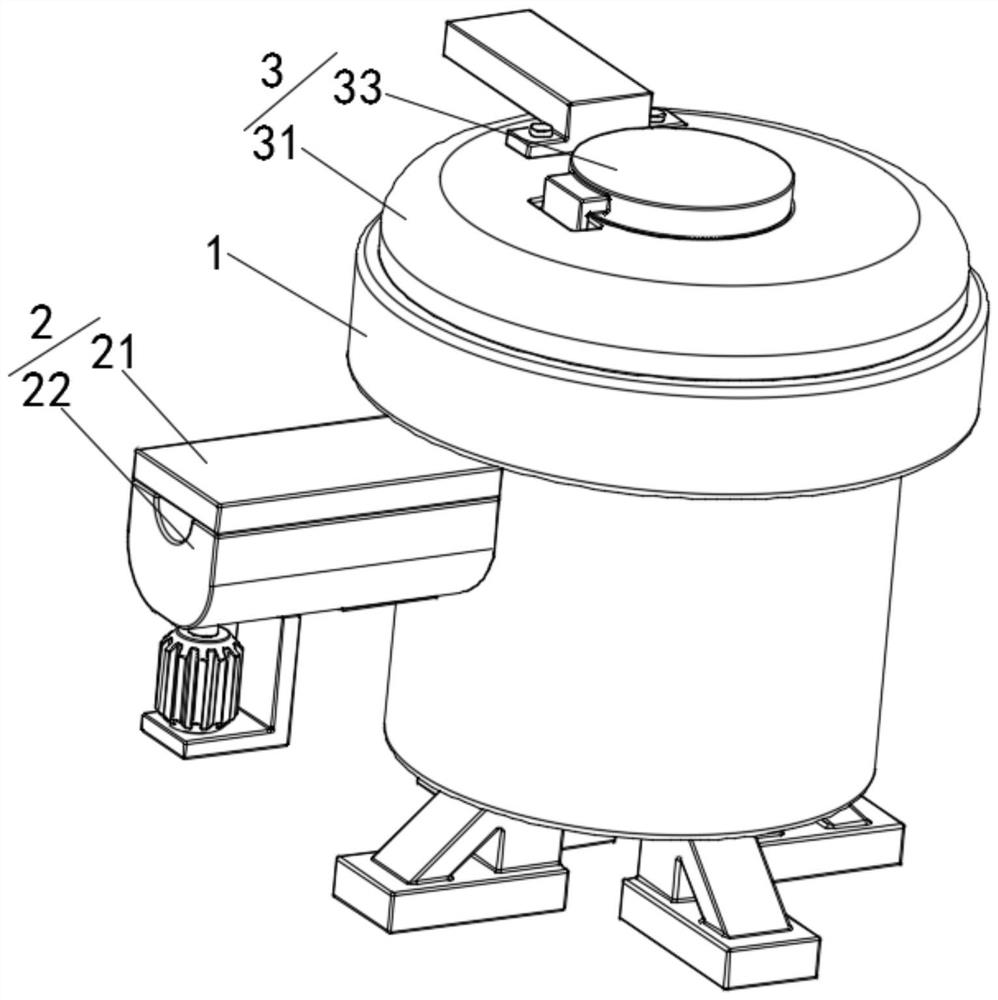

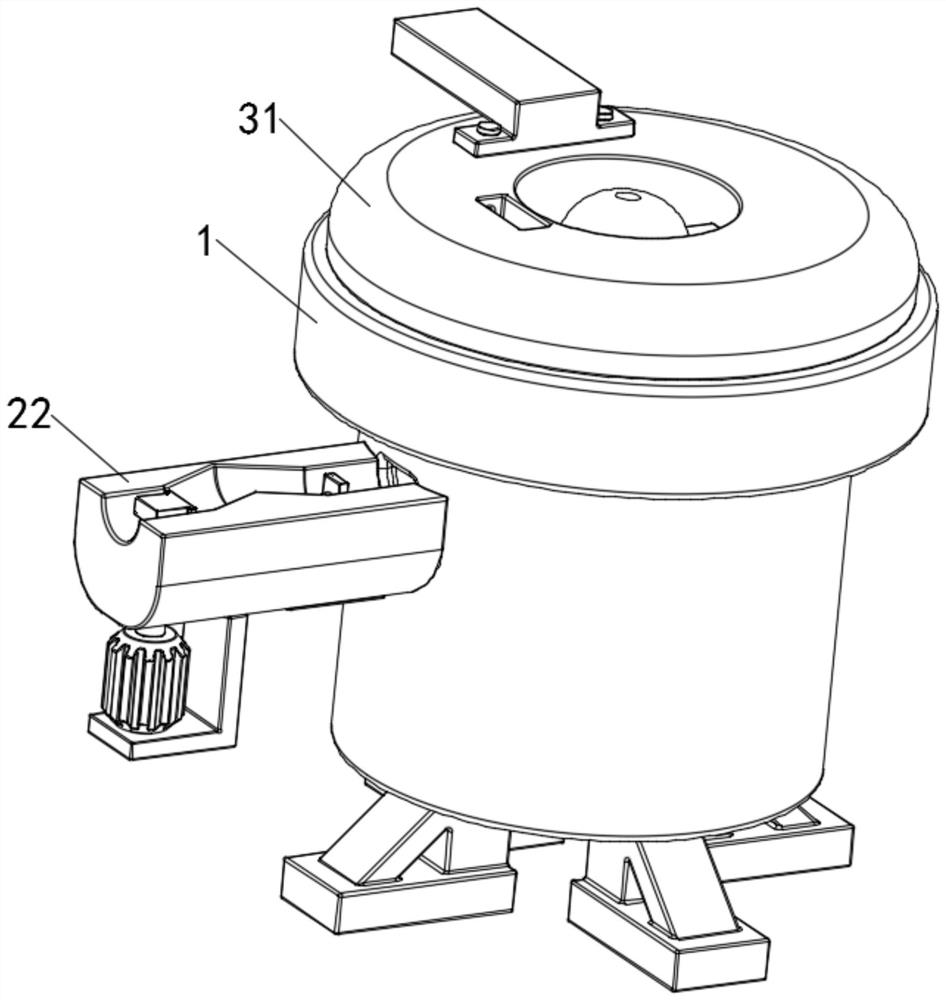

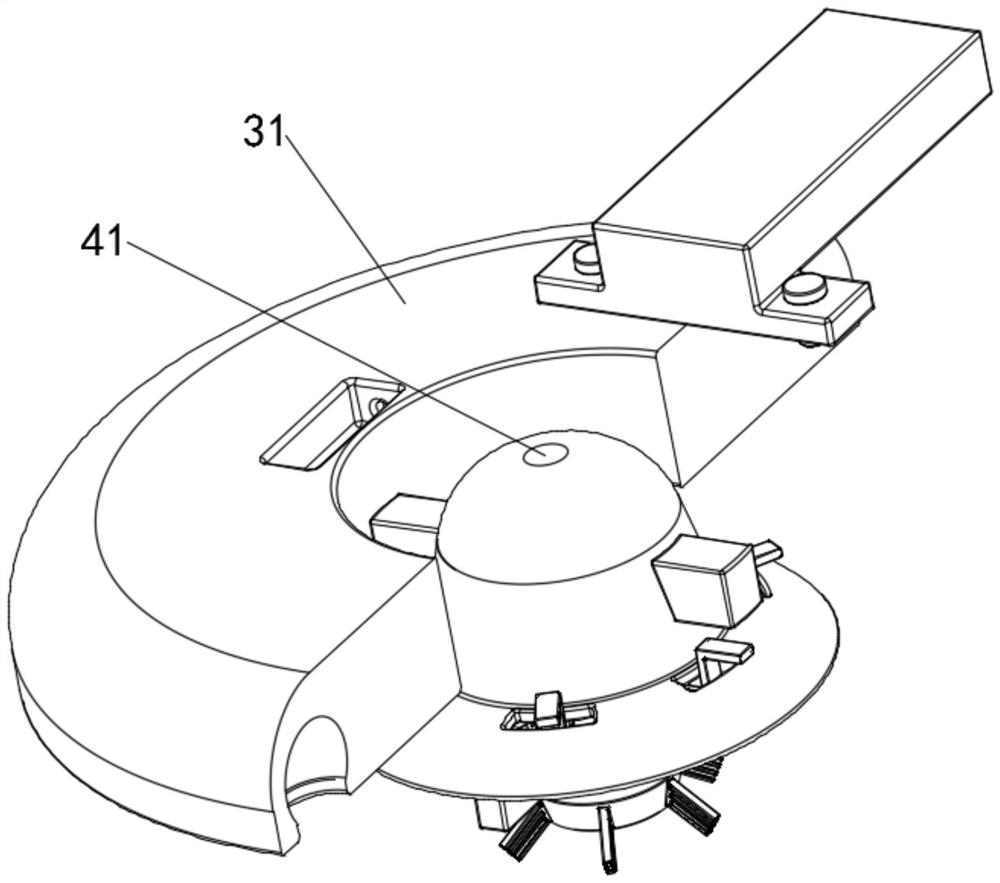

[0042] see Figure 1-Figure 12 , a metal material melting and pulling equipment for improving the comprehensive performance of copper plates, including a melting furnace 1, a pulling device 2 is fixedly installed on the axial outer side of the melting furnace 1, a matching assembly 3 is arranged on the upper side of the melting furnace 1, and the shaft of the matching assembly 3 is provided A discharging device 4 is fixedly installed inward, and an anti-blocking device 5 is fixedly installed on the discharging device 4;

[0043] The pulling device 2 includes a sealing plate 21 , a pulling block 22 , a control device 23 , and a measuring device 24 . The sealing plate 21 is fixedly connected to the axial outer side of the melting furnace 1 , and the axial outer side of the melting furnace 1 is fixed to the lower side of the sealing plate 21 . The traction block 22 is connected. When the melted liquid metal material is dumped and pulled, since the traction block 22 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com