Connector pressure test equipment based on electric power safety

A pressure test and power safety technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc. Deviation and other problems to achieve the effect of improving test efficiency, increasing endurance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

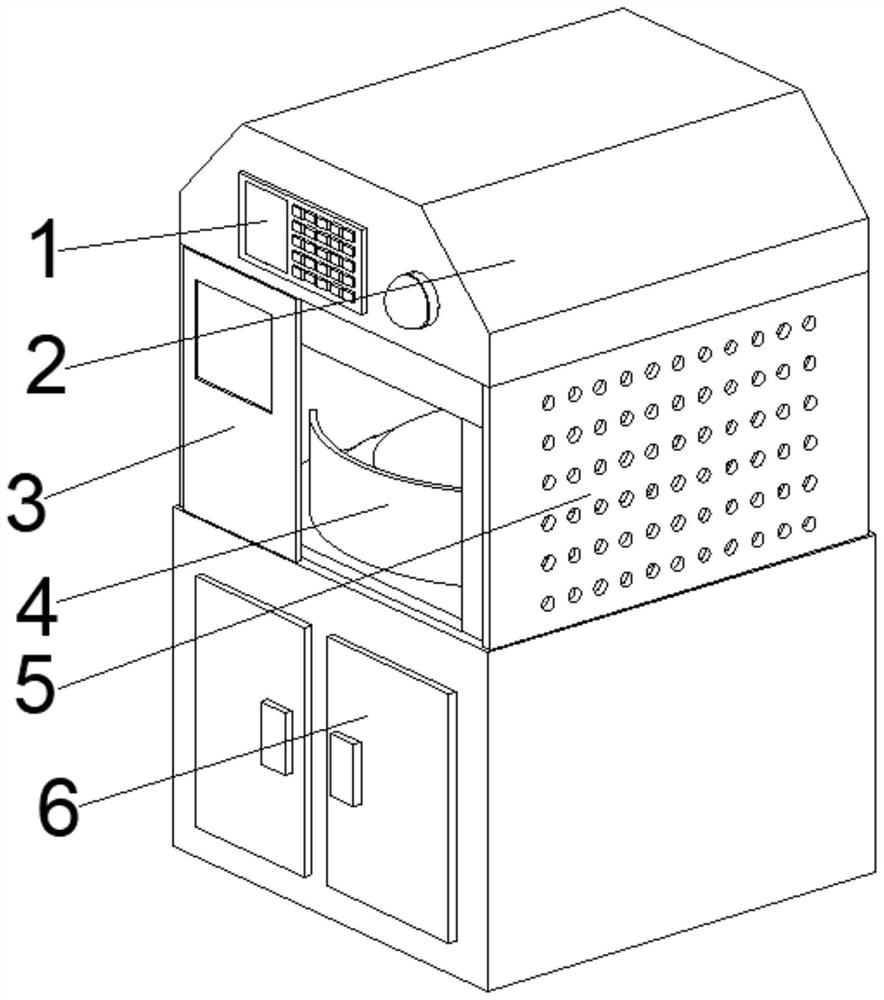

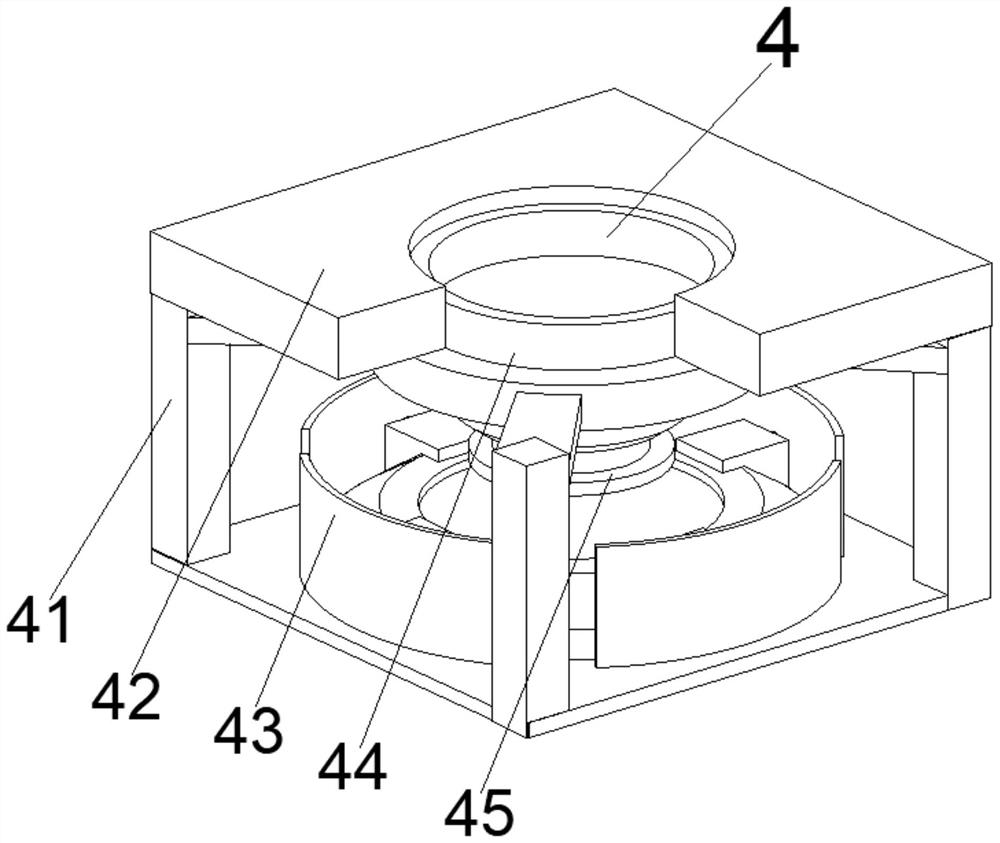

[0038] see Figure 1-Figure 6 , the present invention provides a technical solution: a connector pressure testing device based on electric power safety, including a device main body 6, a detection device 4 is fixedly connected to the top middle of the device body 6, and the detection device 4 is driven by the power box 2 Work from the ground down, and transmit the detected data to the operation panel 1, which is convenient for the staff to observe, thereby avoiding the repeated testing of the qualified connections. The top of the equipment body 6 is located on both sides of the detection device 4 and is fixedly connected Frame 5, the power box 2 is fixedly connected to the top of the frame 5, the operation panel 1 is fixedly connected to the front of the power box 2, and the barrier box door 3 is slidingly connected to the left side of the front of the frame 5. Sliding to make it seal the frame 5 during detection, thereby avoiding the splashing of some impurities during detect...

Embodiment 2

[0045] see Figure 1-Figure 6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using a connector pressure testing device based on electric safety, Step 1: Install the device, and fix the device main body 6 and the frame 5 Connecting, the power box 2 is fixedly connected with the detection device 4, so that the power box 2 drives the detection device 4 to perform detection work, and the equipment main body 6 is connected to the power supply;

[0046] Step 2: The pressure detection of the piece to be tested is carried out by installing the detection cavity generated by the top plate 42 and the fixed column 41, and as the lifting detector 45 is lifted in the vertical direction on the fixing device 44, the fixed column 41 is installed on the top plate 42. Fixedly connected, and fixedly connected the fixed column 41 and the fixing device 44;

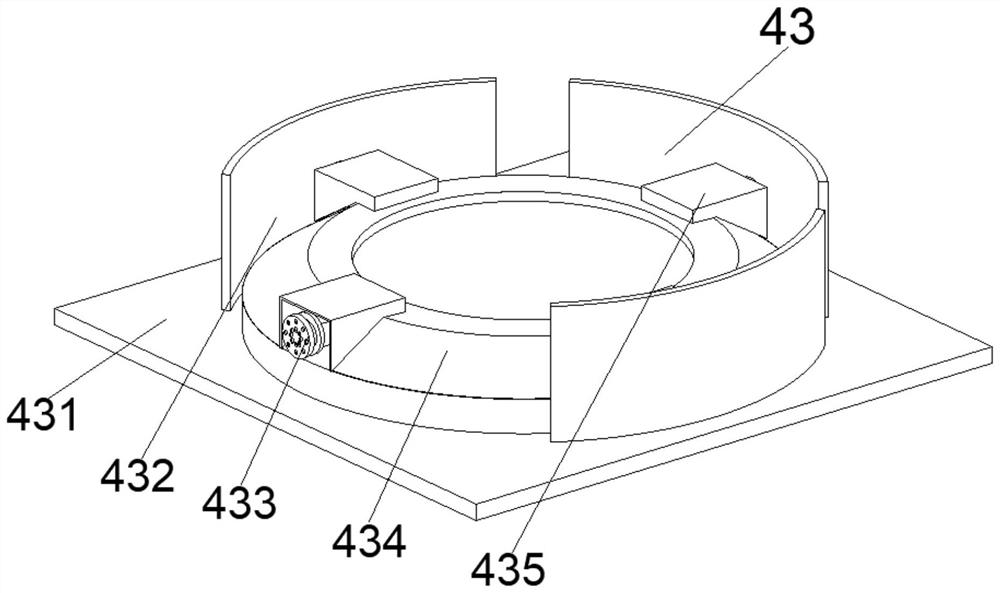

[0047] Step 3: Use the insulating arc plate 432 to slide and lift in the vertical directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com