Megawatt high-speed permanent magnet motor temperature rise calculation method

A technology of permanent magnet motor and calculation method, which is applied in calculation, computer aided design, design optimization/simulation, etc., can solve the problems that it is difficult to meet the actual needs, and can not take into account the calculation speed and accuracy at the same time, so as to avoid the effect of accuracy defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

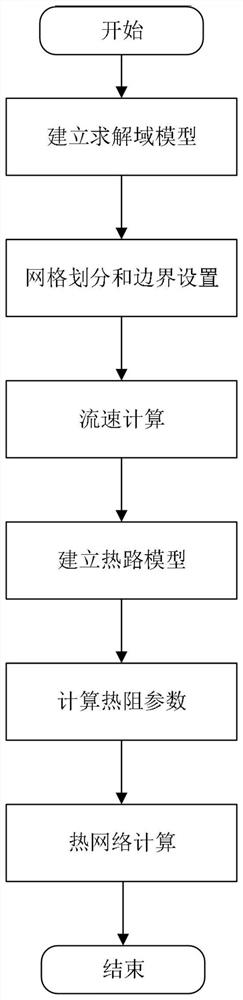

[0065] The following combined embodiments and accompanying drawings are proposed in detail a temperature rise calculation method suitable for megawatt-level high-speed permanent magnet motors proposed in the present invention. These include the following steps:

[0066] Step 1: Establish a physical model of the motor solution domain:

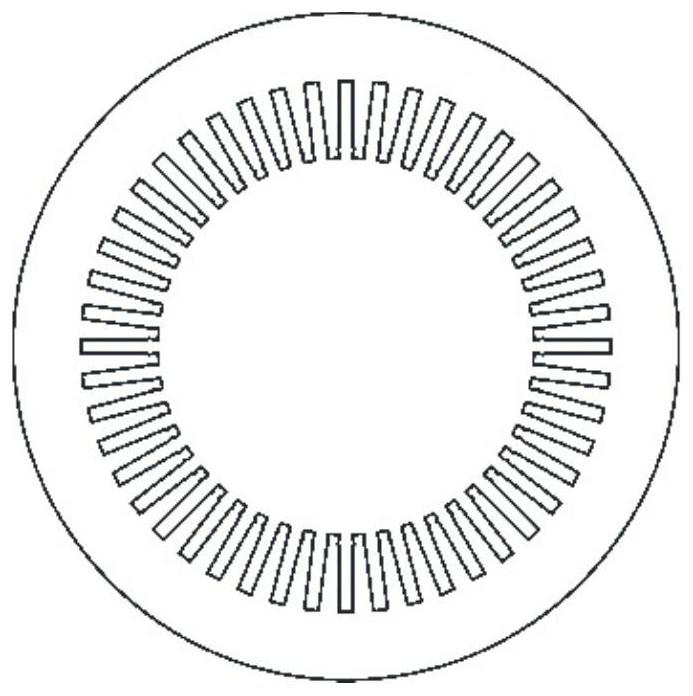

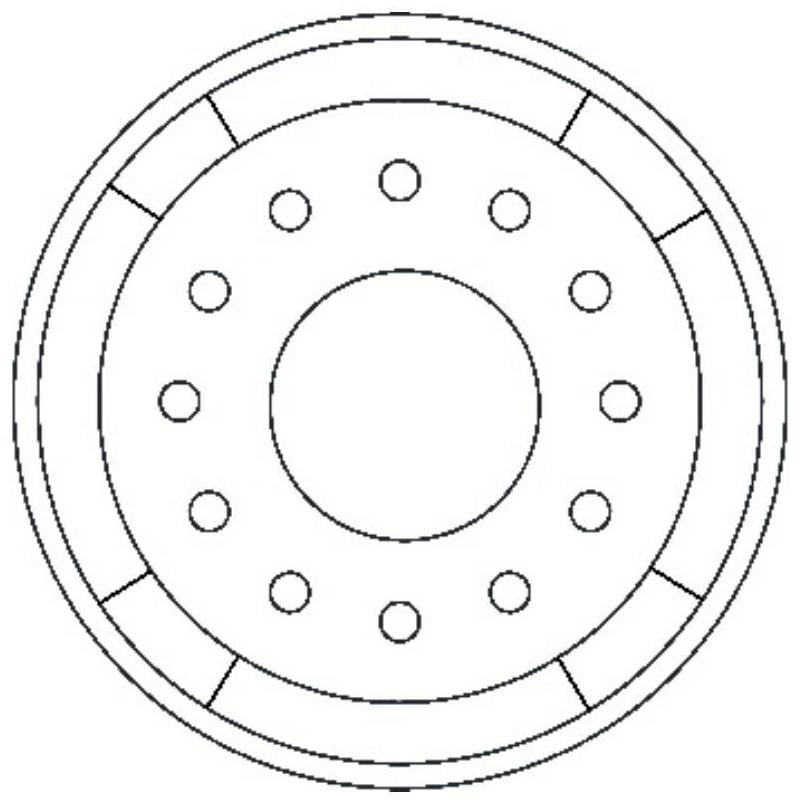

[0067] Taking a 1MW surface-mount high-speed permanent magnet motor as an example, the size parameters of the motor are shown in Table 1, the stator rotor structure is shown in Figure 2, and the stator core adopts a silicon steel sheet superimposed structure. The windings are double-layered and wrapped in insulating material embedded in the stator groove. The permanent magnet is a surface-mount structure, the material is NdFeB35EH, and the carbon fiber sheath is used to fix the permanent magnet with the permanent magnet interference.

[0068] Considering the symmetry of the motor structure in this example, one-twelfth of the motor structure domain is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com