Particle precision seeding device of anti-winding no-tillage combined seed and fertilizer drill

A precision seeding and seeding technology, which is applied in the parts of seeding machine, sowing seeding machine, and sowing, can solve the problems of the effect of seeding effect, adjustment of seeding depth, time-consuming and laborious operation, etc., so as to improve the seeding effect, save labor, expand the The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

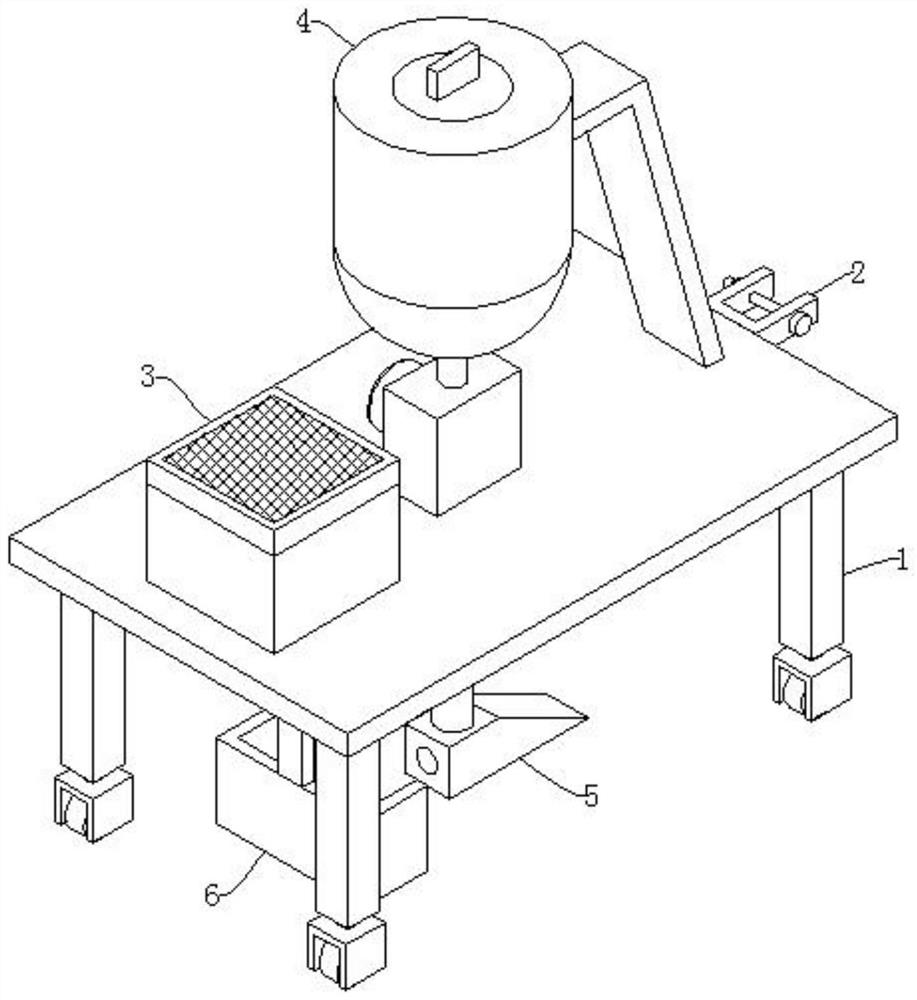

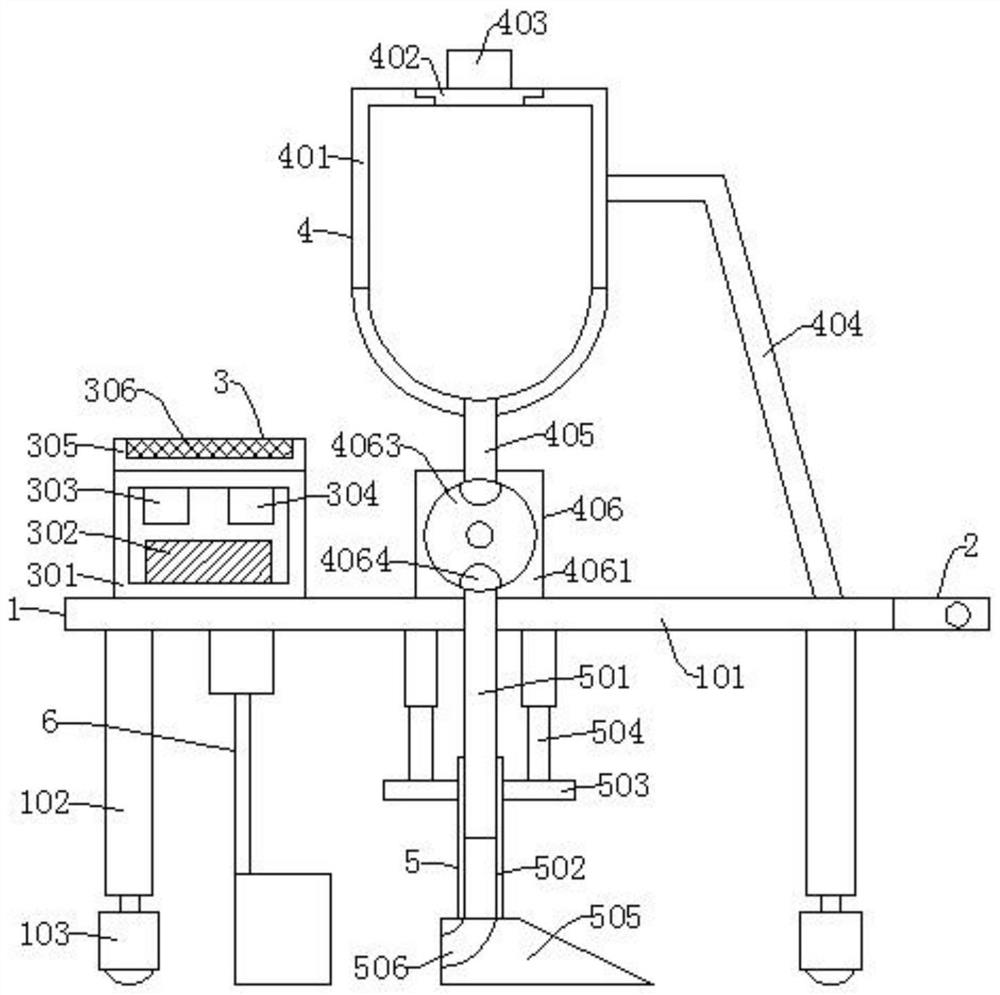

[0050] Such as figure 1 , image 3 , Figure 5 , Figure 7 , Figure 8 As shown, a particle precision seeding device of an anti-winding no-tillage fertilization seeder includes a moving mechanism 1 for driving the device to move, a connecting mechanism 2 for connecting the device with the driving equipment, and providing for the operation of the device. The energy supply mechanism 3 of electric energy, the connecting mechanism 2 is installed on the side of the mobile mechanism 1, the energy supply mechanism 3 is fixed on the top of the mobile mechanism 1, and also includes a feeding mechanism 4 for providing seeds for sowing, and a slotting mechanism for slotting the ground. Groove mechanism 5, the soil sealing mechanism 6 that is used to seal the seed in the soil, the feeding mechanism 4 is arranged on the side of the energy supply mechanism 3, the slotting mechanism 5 is fixed on the moving mechanism 1, and the soil sealing mechanism 6 is arranged on the slotting mechanis...

Embodiment 2

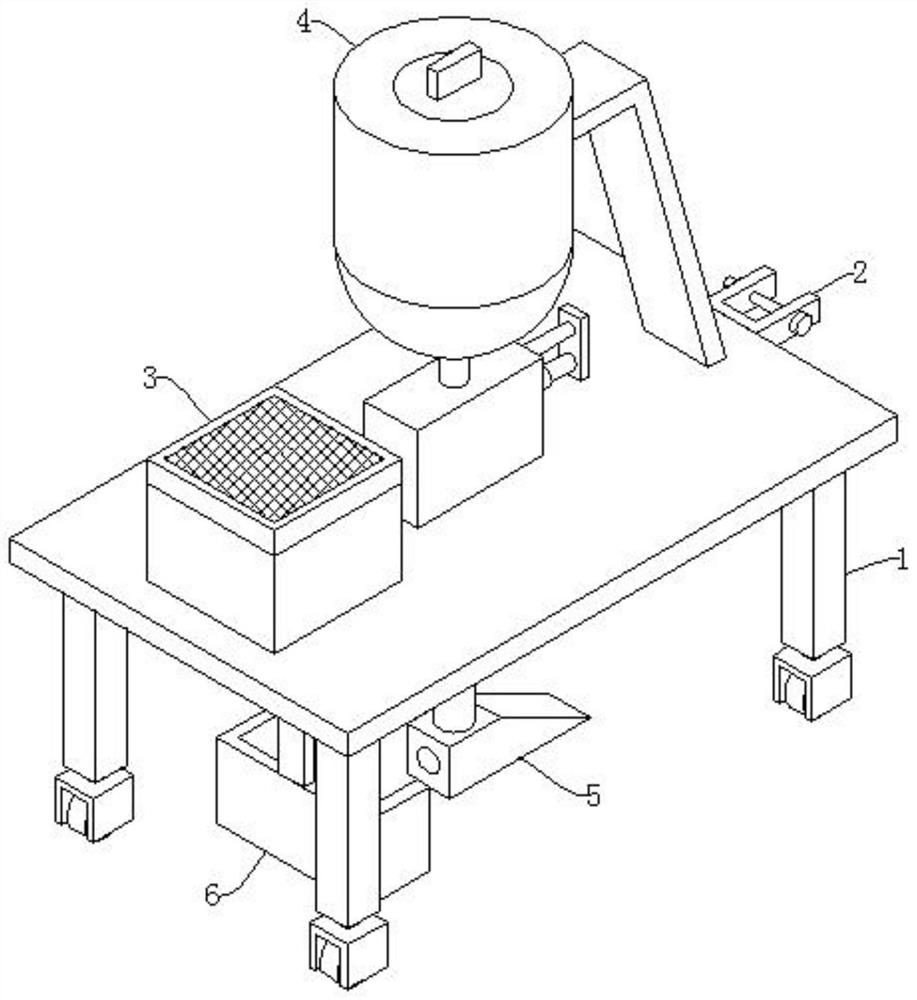

[0057] Such as figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the first fixed shell 4061, the motor 4062, the lower tray 4063, and the lower chute 4064 are replaced by the second fixed shell 4065, the stopper 4066, and the first electric push rod 4067, movable plate 4068, movable rod 4069, blanking plate 40610, and blanking hole 40611. When sowing, the driving device drives the device to move, and the plowshare 505 moves to slot the ground, and the seeds in the storage tank 401 pass through the feeding pipe 405 Entering the blanking hole 40611, the first electric push rod 4067 shrinks and drives the movable plate 4068 to move, the movable plate 4068 drives the blanking plate 40610 to move to the left through the movable rod 4069, and when the blanking plate 40610 moves to the left to a certain position, the blanking hole The seeds in 40611 are completely discharged, and the discharged seeds e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com