Efficient garlic sowing machine

A planter and garlic technology, which is applied to potato planters, planting methods, agricultural machinery and tools, etc., can solve problems such as unsatisfactory soil covering effect and inconvenient trench excavation, so as to improve the sowing effect and make the process compact and orderly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

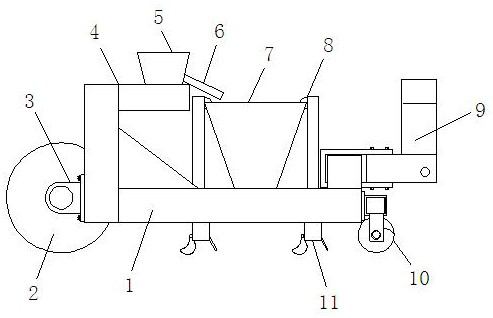

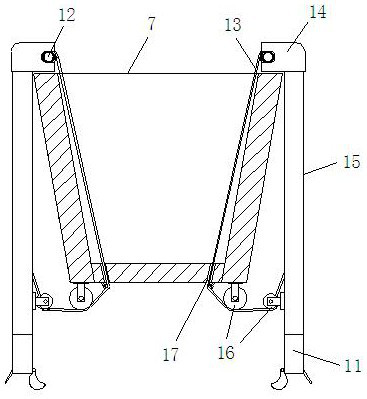

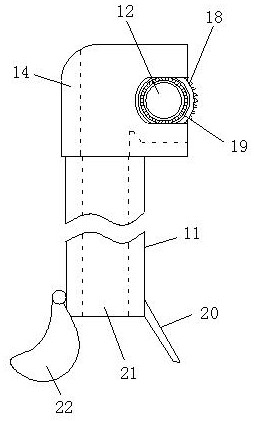

[0028] Example 1, please refer to Figure 1~4 And 6, a high-efficiency garlic seeder, including a chassis 1, the upper rear end of the chassis 1 is fixed with a soil pressure roller 2 through a fixed shaft seat 3, and in order to ensure the soil pressure effect, the soil pressure roller 2 uses a steel plate It is rolled into a cylindrical shape, and the inside is hollow to reduce the weight and avoid the situation that the soil is under pressure when it is too heavy to press the soil. The fixed shaft seat 3 is welded to the lower fixed iron 26, and the upper fixed iron 26 is provided with a There is an upper fixed iron 24, the upper fixed iron 24 is welded to the upper bottom position of the bottom frame 1, and the upper fixed iron 24 is screwed with an adjusting screw rod 25 between the lower fixed irons 26, and the corresponding lower fixed iron 26 position on the bottom frame 1 is also A fixed plate 30 is welded, and the fixed plate 30 is fixed between the lower fixed irons...

Embodiment 2

[0031] Example 2, please refer to Figure 1-7, a high-efficiency garlic seeder, comprising an underframe 1, the upper rear end of the underframe 1 is fixed with a soil pressure roller 2 through a fixed shaft seat 3, and in order to ensure the soil pressure effect, the soil pressure roller 2 is rolled into a steel plate It is made in a cylindrical shape, and the inside is hollow to reduce the weight and avoid the situation that the soil is under pressure when it is too heavy to press the soil. The fixed shaft seat 3 is welded to the lower fixed iron 26, and an upper Fixed iron 24, the upper fixed iron 24 is welded on the bottom position of the bottom frame 1, the upper fixed iron 24 is screwed with an adjusting screw rod 25 between the lower fixed irons 26, and the corresponding lower fixed iron 26 position is also welded on the bottom frame 1 The fixed plate 30, the fixed plate 30 is fixed with the fixed bolts 27 staggered with the adjusting screw rod 25 between the lower fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com