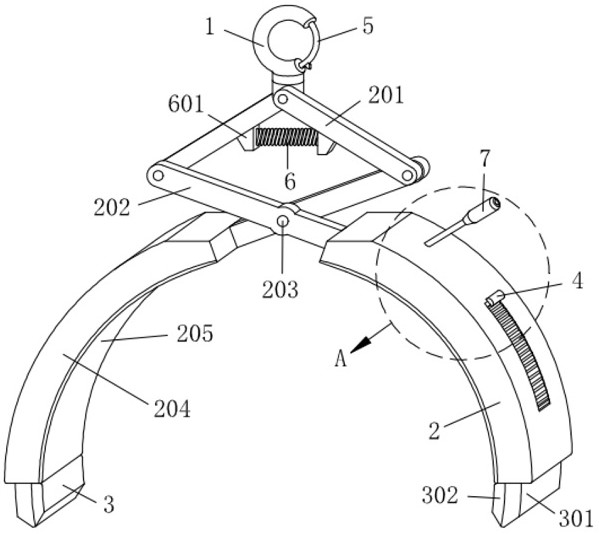

Goods loading and unloading device for glass fiber plastic pipe transportation

A technology of cargo handling and glass fiber, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inconvenient operation, reduced efficiency, cumbersome disassembly, etc., and achieve convenient lifting and handling, convenient operation, and firm and stable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

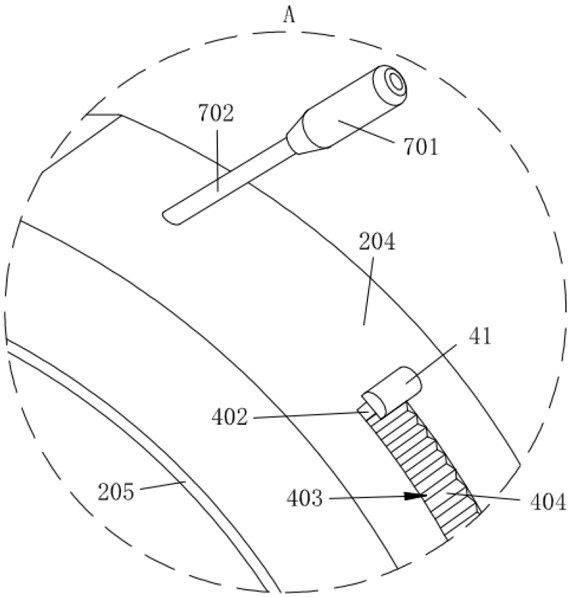

[0028] Specifically, the pressure rod 402 is an "L"-shaped structure, and a pressure plate 401 is fixedly connected to the pressure rod 402, and the pressure plate is

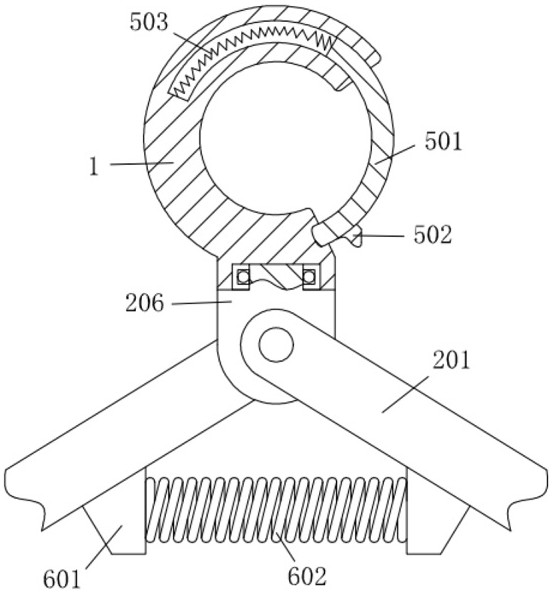

[0029] Specifically, the snap mechanism 5 includes a snap 501, one end of the hook 1 is installed with a snap 501, and the snap

[0031] Specifically, the protection mechanism 7 includes a gear plate 706, wherein a gear is installed inside one of the drive rods 202

[0032] Specifically, the screw 702 is provided with an anti-skid sleeve 701, and the anti-skid sleeve 701 is a truncated cone-shaped structure.

[0034] It will be apparent to those skilled in the art that the invention is not limited to the details of the above-described exemplary embodiments, but also

[0035] Furthermore, it should be understood that although this specification is described in terms of embodiments, not every embodiment includes only

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com