Rope head sliding warning device with pressing plate for fixing tail end of steel wire rope

A warning device and wire rope technology, which is applied in hoisting devices, clockwork mechanisms, sea area projects, etc., can solve the problems of not being able to observe the fixing of the rope head in time, related to the safety of project operation, and existing safety hazards, etc., to achieve easy installation and disassembly, ensuring the safety of equipment and engineering, and avoiding the effect of rope slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

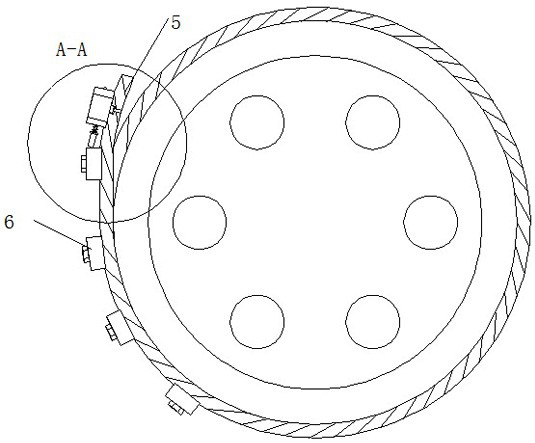

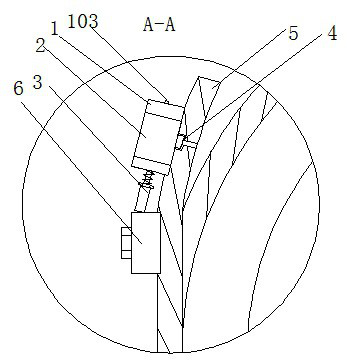

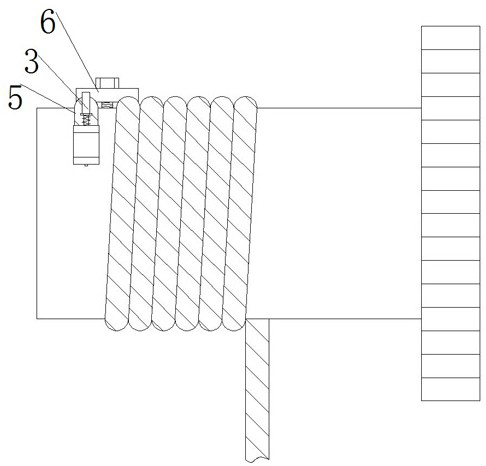

[0027] Such as figure 1 , 2 , shown in 3, the wire rope is wound around the drum and fixed by the drum pressing plate 6, and the rope head sliding warning device at the end of the wire rope tail end is fixed on the wire rope rope head 5 by the contact housing 201 of the elastic contact assembly 2.

[0028] Such as Figure 4 As shown, the pressure plate fixes the rope end sliding warning device at the end of the steel wire rope, including an audible and visual warning assembly 1, an elastic contact assembly 2 and a top pressure switch assembly 3. It is connected in a rotating and separate manner. The top pressure switch assembly 3 is movably plugged into its inner end through the socket on the elastic contact assembly 2. The elastic contact assembly 2 is fixed on the wire rope head 5 through the buckle 4. The other end of the pull-down switch assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com