A prefabricated concrete wall panel steel structure connecting device

A connecting device and concrete technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of low correction accuracy, inability to install and correct concrete wall panels and foundations, and cumbersome operations, so as to improve structural stability and improve Precise stability and enhanced connection tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

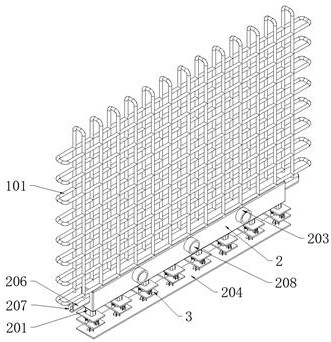

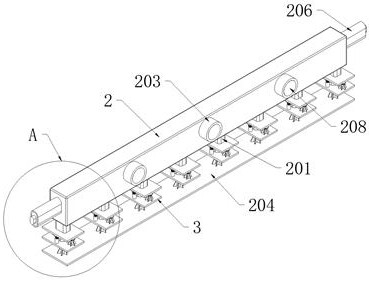

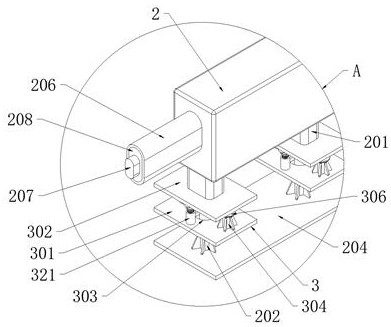

[0048] see Figure 1-12 , a prefabricated concrete wall panel steel structure connection device, comprising a foundation, a wall panel main body 1 and a reinforced frame 101 fixedly installed therein, the bottom of the reinforced frame 101 is fixedly connected with a connection box 2 embedded in the wall panel main body 1, And the bottom of the connection box 2 is evenly fixed with a plurality of plugs 201 extending to the outer end wall of the bottom of the wall panel main body 1. The interior of each plug 201 is vertically inserted with a connecting rod 202, and the bottom of the connecting rod 202 is connected to the foundation. Fixed connection, the front of the connection box 2 is fixedly installed with a plurality of filling ports 203 extending to the outer end wall of the wall panel main body 1, the outer side of each connecting rod 202 is sleeved with a calibration component 3, the interior of the connection box 2 and the calibration The outside of the module 3 is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com