Airtightness detection device for electronic control shell of new energy automobile

A new energy vehicle, air tightness detection technology, used in the liquid/vacuum degree for liquid tightness measurement, electric vehicles, workpiece clamping devices, etc. and other problems to achieve the effect of improving the use effect and preventing damage to the electric housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

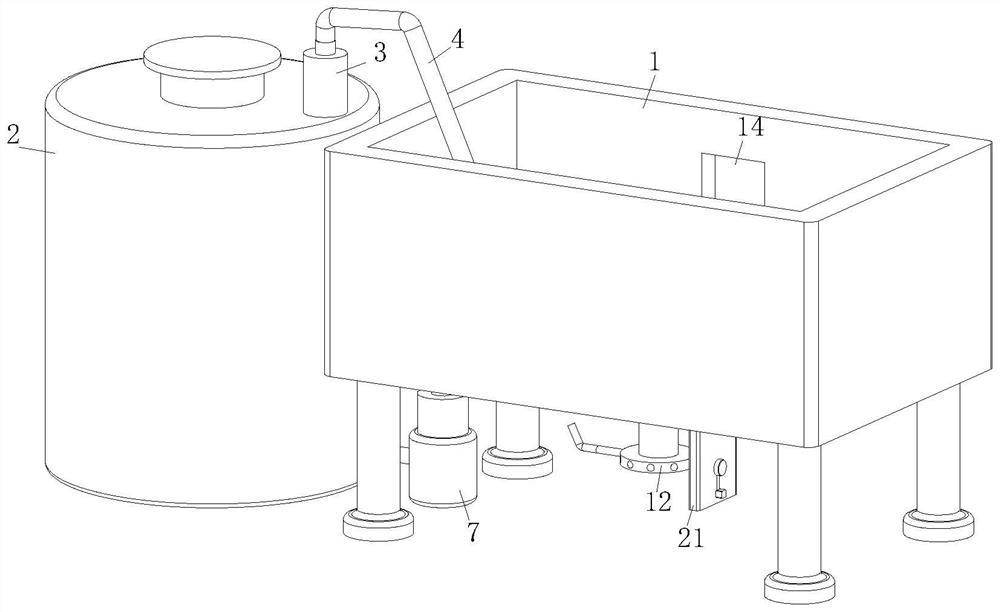

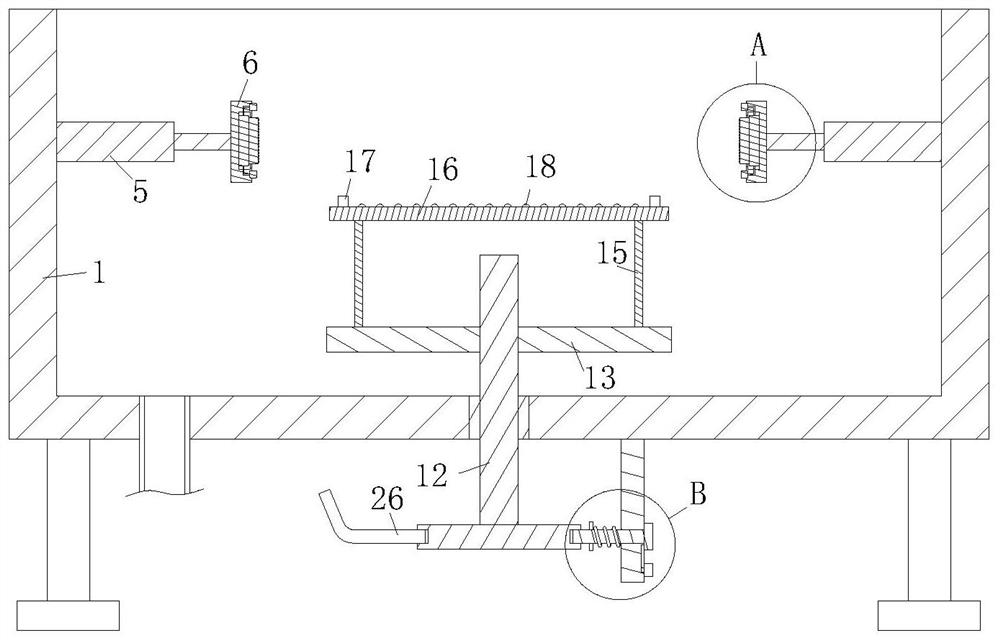

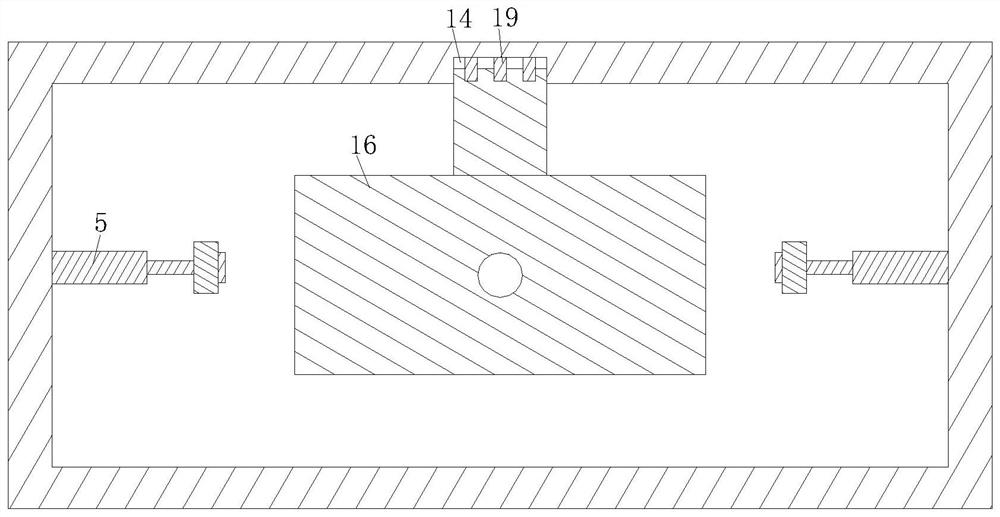

[0026] see Figure 1-5 As shown, an airtight detection device for an electric control housing of a new energy vehicle includes a device main body 1 and a circulating water tank 2 placed on one side of the device main body 1, and a No. 1 water pump 3 is fixed on the upper end of the circulating water tank 2. The upper end of the No. 1 water pump 3 is equipped with a guide tube 4, and the guide tube 4 is connected to the inside of the device main body 1, and the inside of the device main body 1 is equipped with an electric push rod 5, and the end of the electric push rod 5 A clamping plate 6 is fixed on the upper part, the surface of the clamping plate 6 is provided with a fastening structure, and the lower end of the main body 1 of the device is equipped with a No. 2 water pump 7; First place the electric control housing inside the main body 1 of the device, and simultaneously control two sets of electric push rods 5, use the clamping plate 6 to cooperate with the fastening str...

Embodiment 2

[0035] see Figure 6 As shown in Comparative Example 1, as another embodiment of the present invention, the surface of the extruded plate 9 is fixed with anti-slip strips 27, and the anti-slip strips 27 are arranged in a line array on the surface of the extruded plate 9; When the extrusion plate 9 fixes the electric control housing, it will squeeze the anti-slip strip 27, and the friction force between the extrusion plate 9 and the electric control housing can be increased through the anti-slip sleeve, thereby improving the fixing effect and making the electric control housing The body is more stably placed inside the main body 1 of the device.

[0036] Working principle, when testing the airtightness of the electric control housing of the automobile, it is necessary to place the electric control housing inside the main body 1 of the device, and by turning the threaded rod 12, the sliding plate 13 on the surface can be moved on the threaded rod 12, so that the The placing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com