Rotating shuttle anti-lock mechanism

A technology of shuttle guard and rotary hook frame, which is applied in the direction of sewing machine collar mechanism, sewing machine components, sewing machine control device, etc., can solve the problems affecting work efficiency and cumbersome operation, so as to improve production efficiency, avoid impact and reduce damage. Effect of chance of getting stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

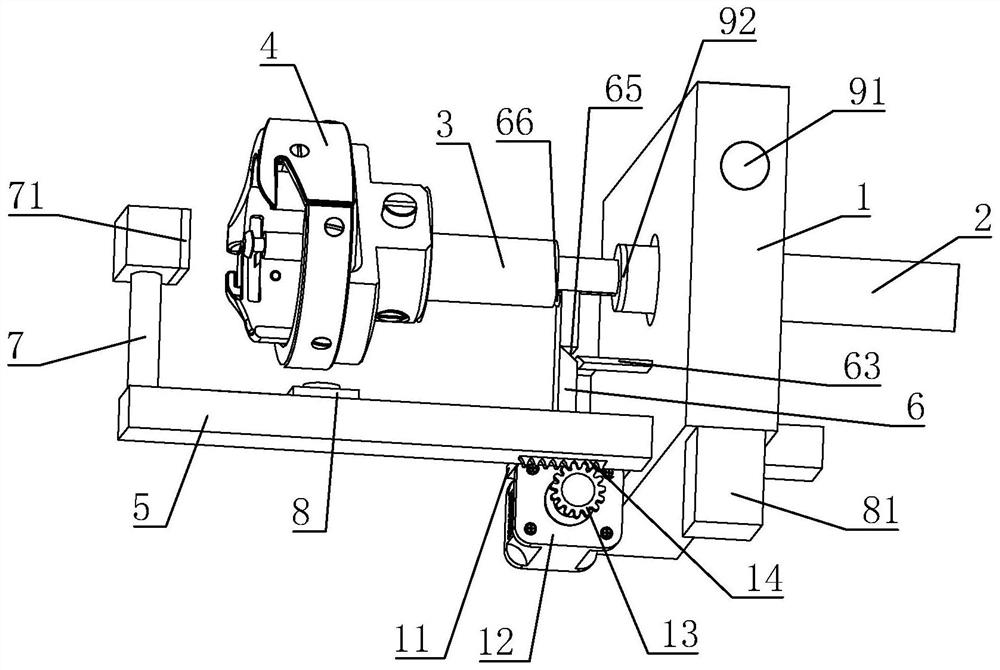

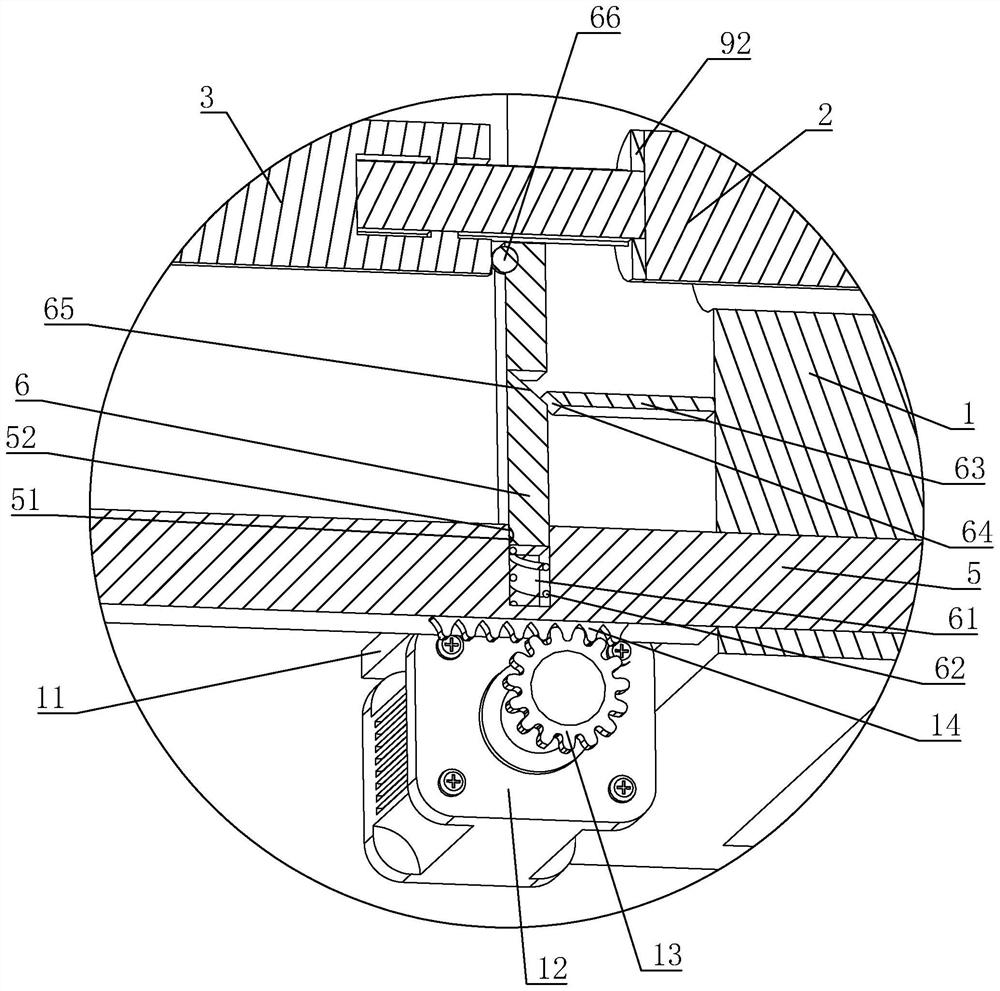

[0026] The present application will be further described in detail below with reference to the accompanying drawings.

[0027] This embodiment: a rotary hook anti-lock mechanism, refer to figure 1 and figure 2 , including: a rotary hook frame 1 and a first rotary shaft 2 rotatably connected to the rotary hook frame 1 through a bearing, the end of the first rotary shaft 2 is slidably connected with a second rotary shaft 3 along the extension direction of the first rotary shaft 2, and the end of the first rotary shaft 2 is slidably connected The second shaft 3 is provided with a guide groove for sliding, the end of the second shaft 3 away from the first shaft 2 is installed with a rotary hook 4, and the sewing machine is installed with a clutch motor for driving the first shaft 2 to rotate.

[0028] When the sewing machine is working, the clutch motor drives the first rotating shaft 2 to rotate at a constant speed, the first rotating shaft 2 drives the second rotating shaft 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com