Method and device for recovery of energy from media containing combustible substances even at low concentration

A technology for recovering energy and substances, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of high energy cost and difficult thermal energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

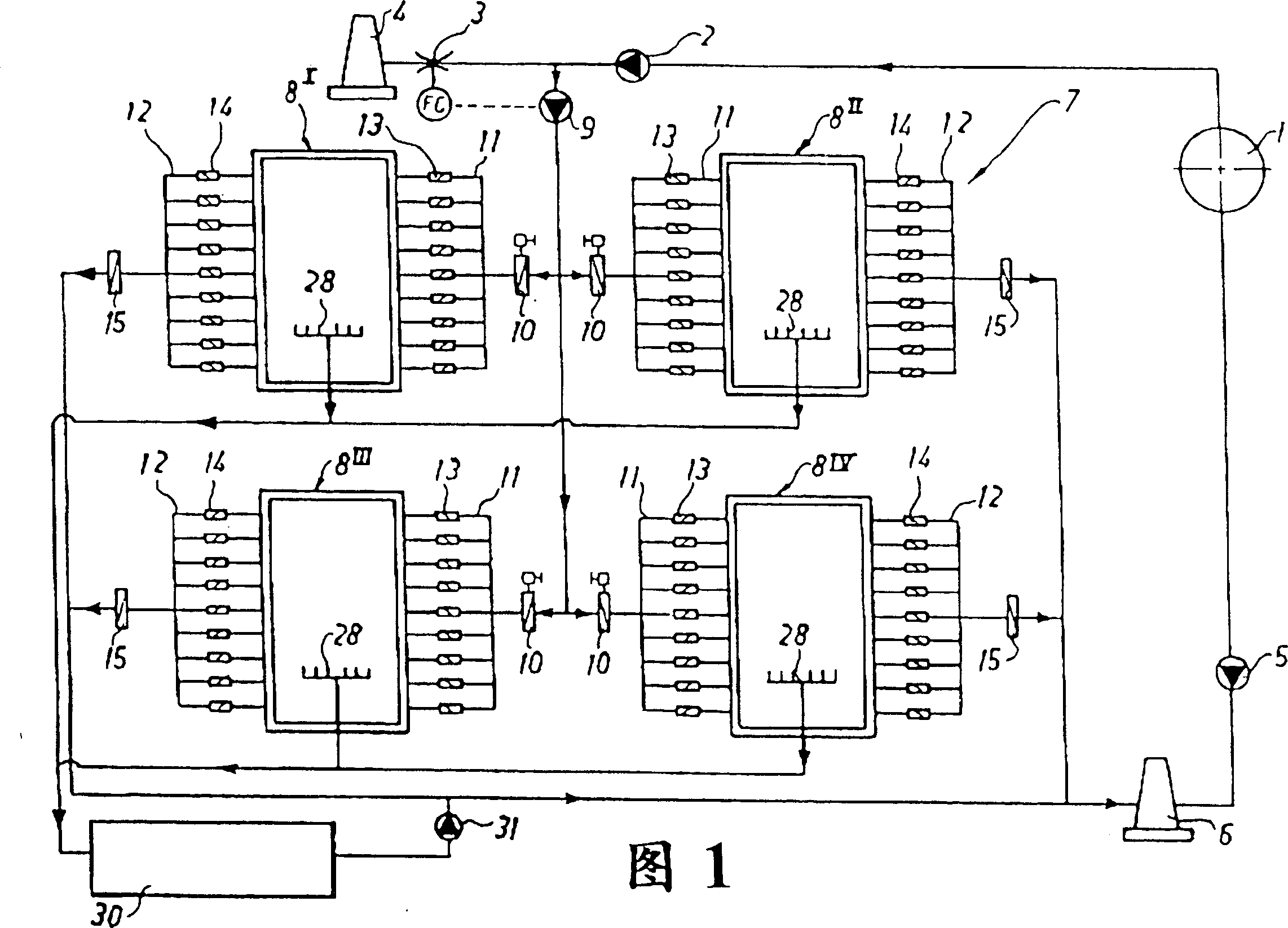

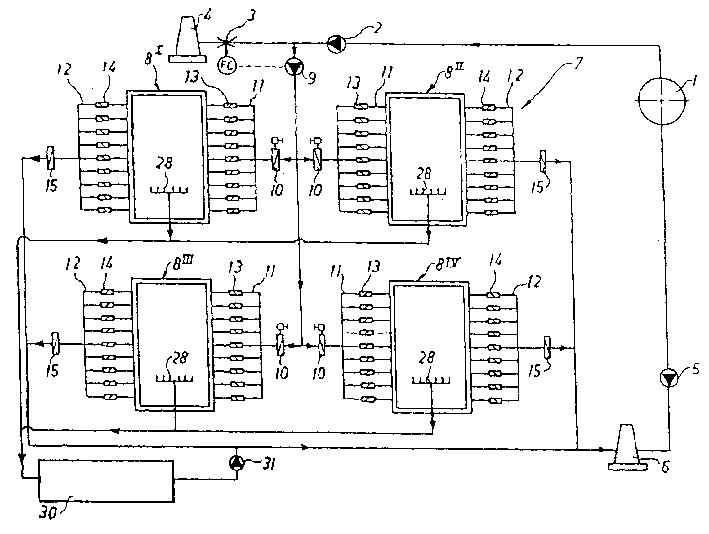

[0014] The device shown in FIG. 1 is used to purify a medium, in this case gas discharged or exchanged from a coal mine. Such exhaust gases often contain flammable substances, flammable methane gas. When the inventive device indicated generally at 7 is not in use, the waste air in the mine 1 is sent to the flue 4 by the fan 2 and the valve 3 or to the flue 6 by the fan 5 .

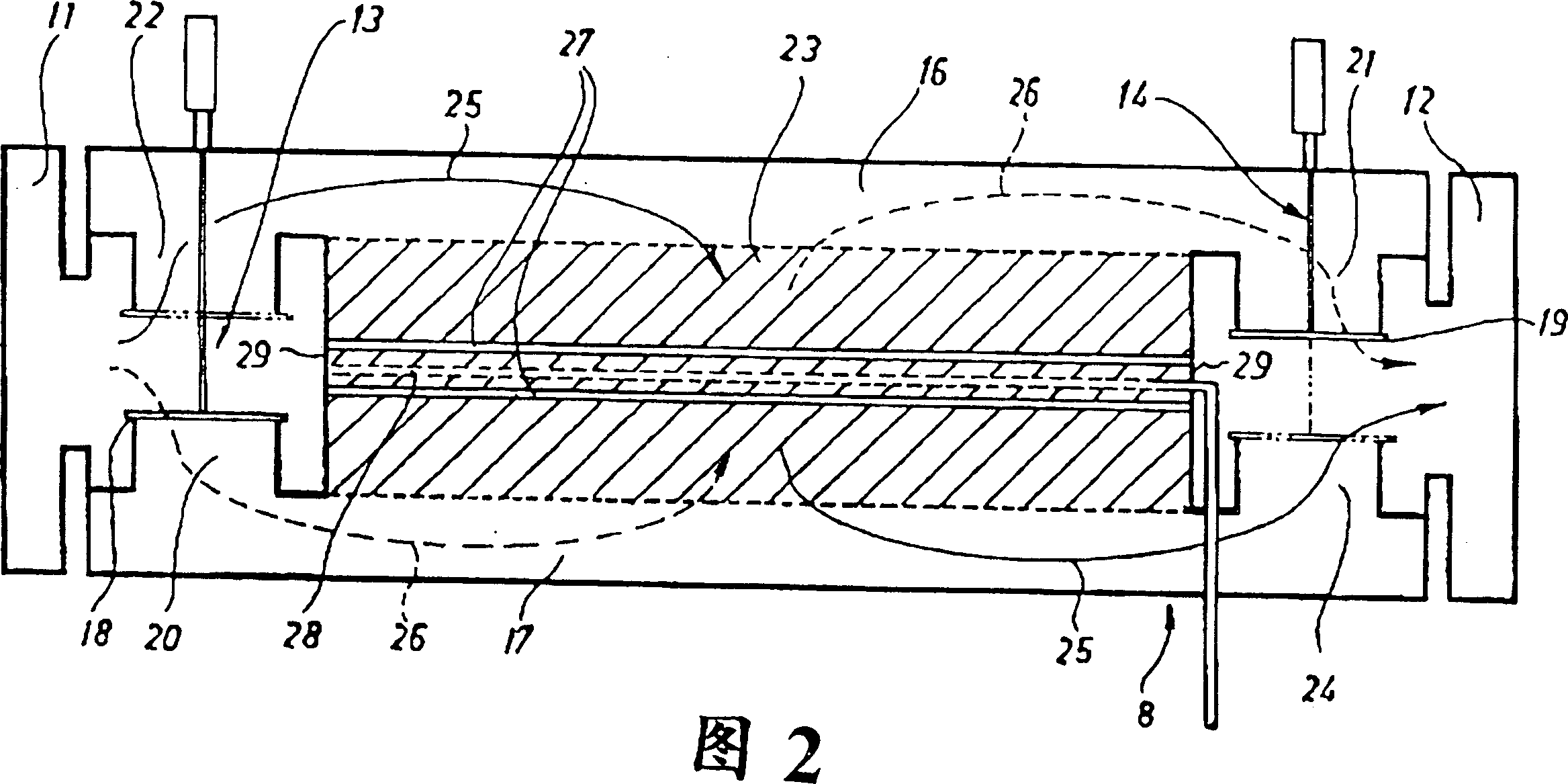

[0015] According to the embodiment shown, the device 7 proposed by the invention comprises four combustion exchangers, which are generally designated 8, 8 I ,8 II ,8 III ,8 IV Indicates that, of course, depending on the field of application, it may also include more or less combustion exchangers. Each combustion exchanger 8 is connected with a plurality of inlet pipes 11 and a plurality of outlet pipes 12 through a process fan 9 shared by all combustion exchangers and a valve 10 provided for each combustion exchanger. According to the embodiment shown, there are 9 inlet conduits and 9 outlet conduits,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com