Butter adding device for supporting ring of concrete truck

A technology for concrete transport vehicles and adding devices, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., and can solve problems such as easy wear, inconvenient adding lubricating oil, replacement and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

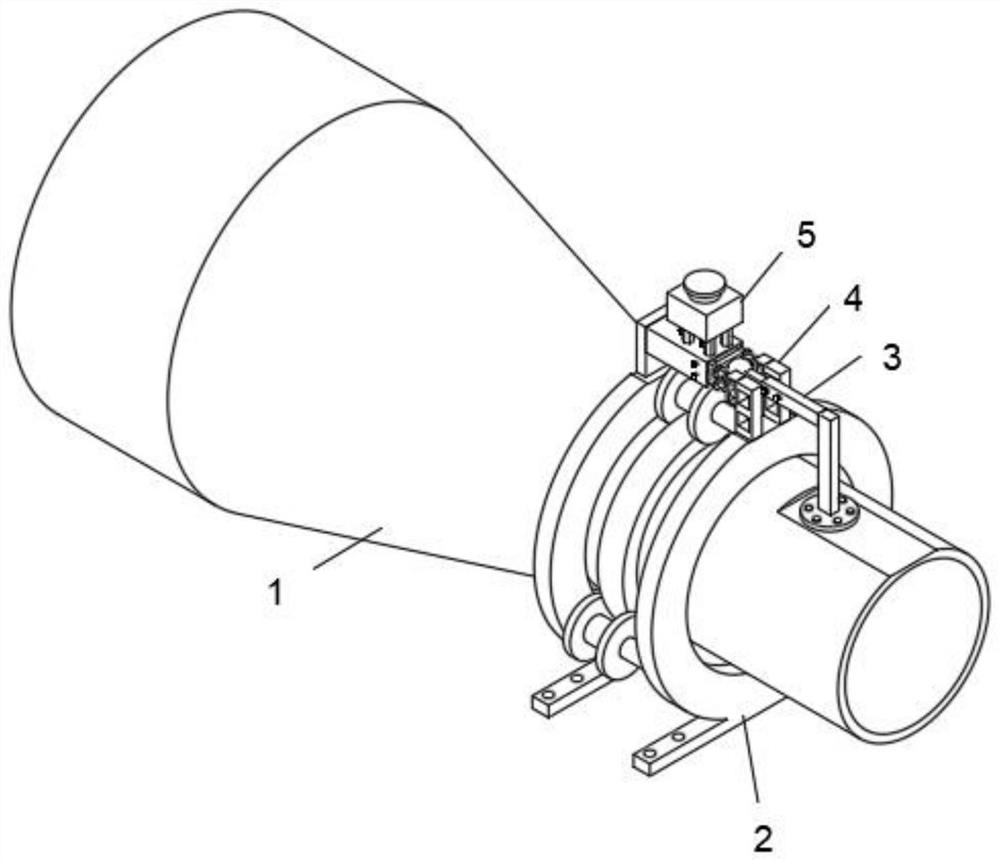

[0040] like figure 1 , a grease adding device for a support ring of a concrete transport vehicle, comprising a barrel 1, a limit support device 2, an automatic extrusion device 3, an auxiliary extrusion device 4 and an adding device 5, and one end of the barrel 1 is fixedly installed with a rotating A support snap ring 10, the rotating support snap ring 10 is rotated and clamped inside the limit support device 2, the automatic extrusion device 3 is fixedly connected to the outer end of the barrel 1, and the auxiliary extrusion device 4 is symmetrically fixed The adding device 5 is fixedly installed on the upper end of the other side of the limiting support device 2 . During the rotation of the barrel 1, the support snap ring 10 is rotated and clamped to the inside of the limit support device 2 to play a supporting role, and during the rotation of the barrel 1, the front end of the automatic extrusion device 3 and the addition The bottom of the device 5 is squeezed, so that th...

Embodiment 2

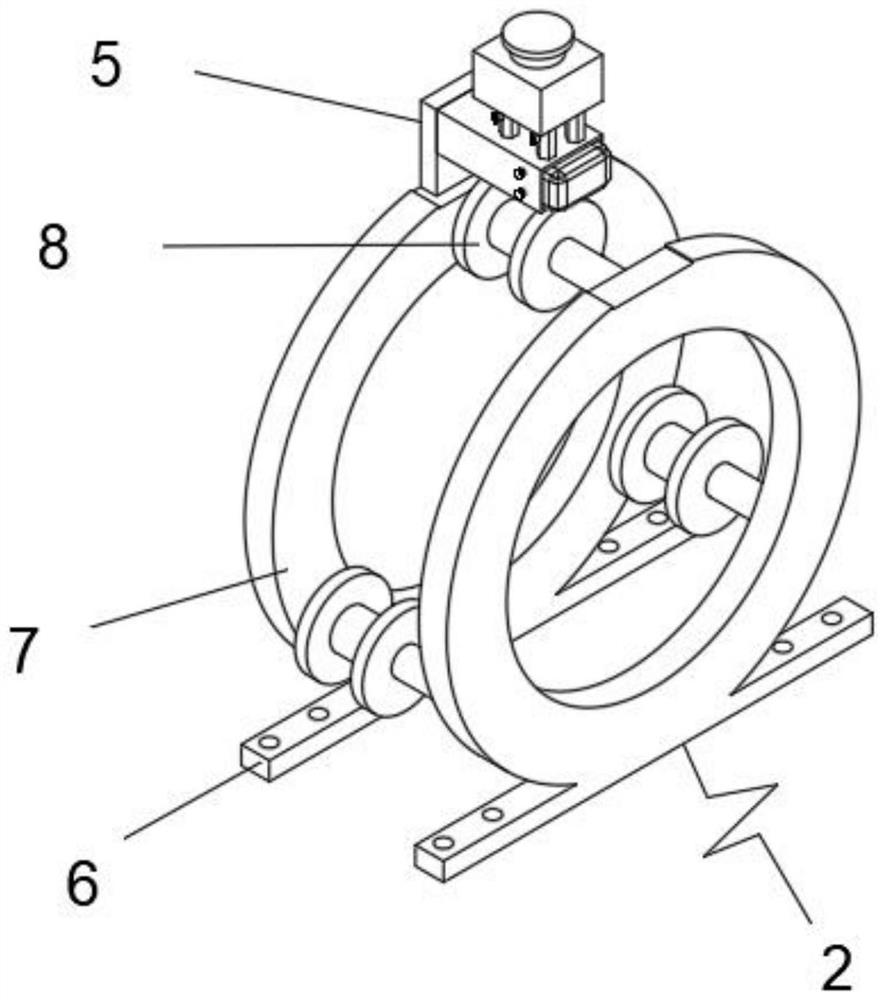

[0042] like figure 2 , as a further optimization scheme of the above-mentioned embodiment: a grease adding device for the support ring of a concrete transport vehicle, including a barrel 1, a limit support device 2, an automatic extrusion device 3, an auxiliary extrusion device 4 and an addition device 5, the described One end of the barrel 1 is fixedly installed with a rotating support snap ring 10, the rotating support snap ring 10 is rotatably clamped inside the limit support device 2, and the automatic extrusion device 3 is fixedly connected to the outer end of the barrel 1, The auxiliary pressing device 4 is symmetrically and fixedly installed on one upper end of the limiting support device 2 , and the adding device 5 is fixedly mounted on the other upper end of the limiting support device 2 . The limit support device 2 includes a fixed plate 6, a support ring 7 and a rotating support shaft 8. There are two support rings 7, and the fixed plate 6 is fixedly connected to t...

Embodiment 3

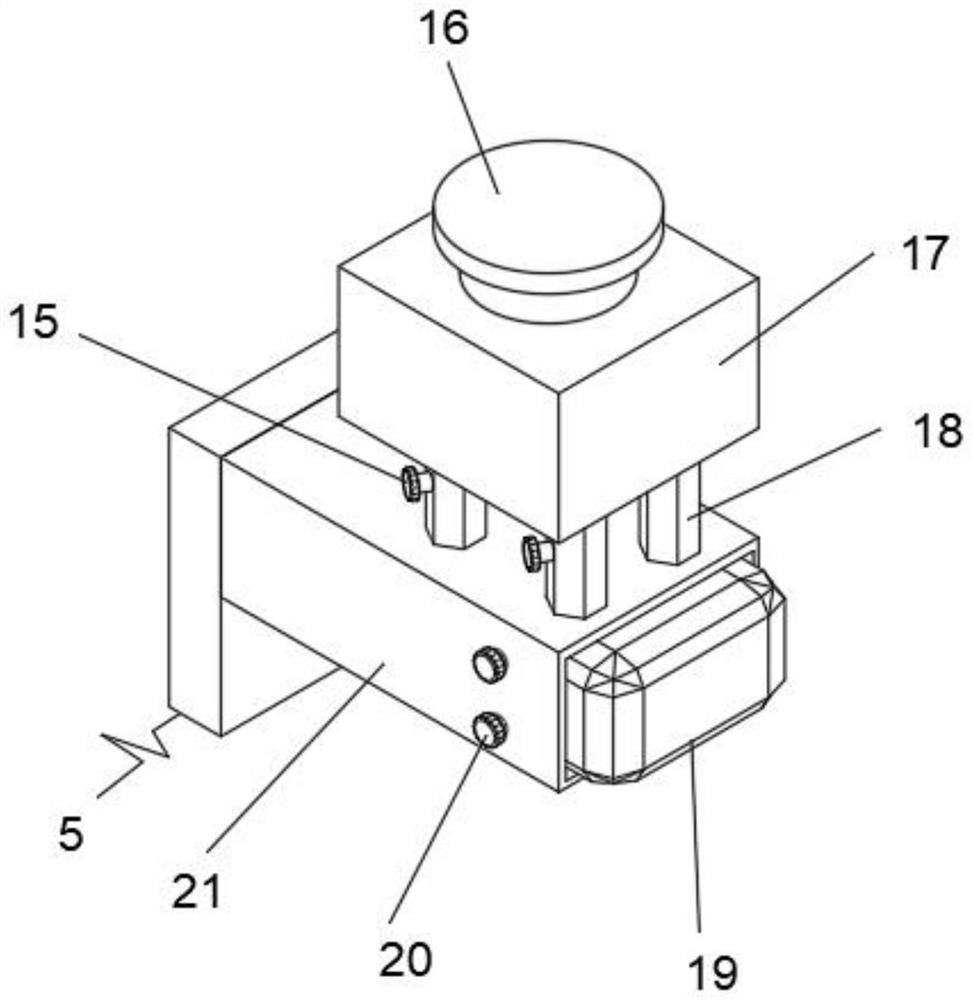

[0044] like Figure 3-4 , as a further optimization scheme of the above-mentioned embodiment: a grease adding device for the support ring of a concrete transport vehicle, including a barrel 1, a limit support device 2, an automatic extrusion device 3, an auxiliary extrusion device 4 and an addition device 5, the described One end of the barrel 1 is fixedly installed with a rotating support snap ring 10, the rotating support snap ring 10 is rotatably clamped inside the limit support device 2, and the automatic extrusion device 3 is fixedly connected to the outer end of the barrel 1, The auxiliary pressing device 4 is symmetrically and fixedly installed on one upper end of the limiting support device 2 , and the adding device 5 is fixedly mounted on the other upper end of the limiting support device 2 . The limit support device 2 includes a fixed plate 6, a support ring 7 and a rotating support shaft 8. There are two support rings 7, and the fixed plate 6 is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com