Patents

Literature

35results about How to "Badly worn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

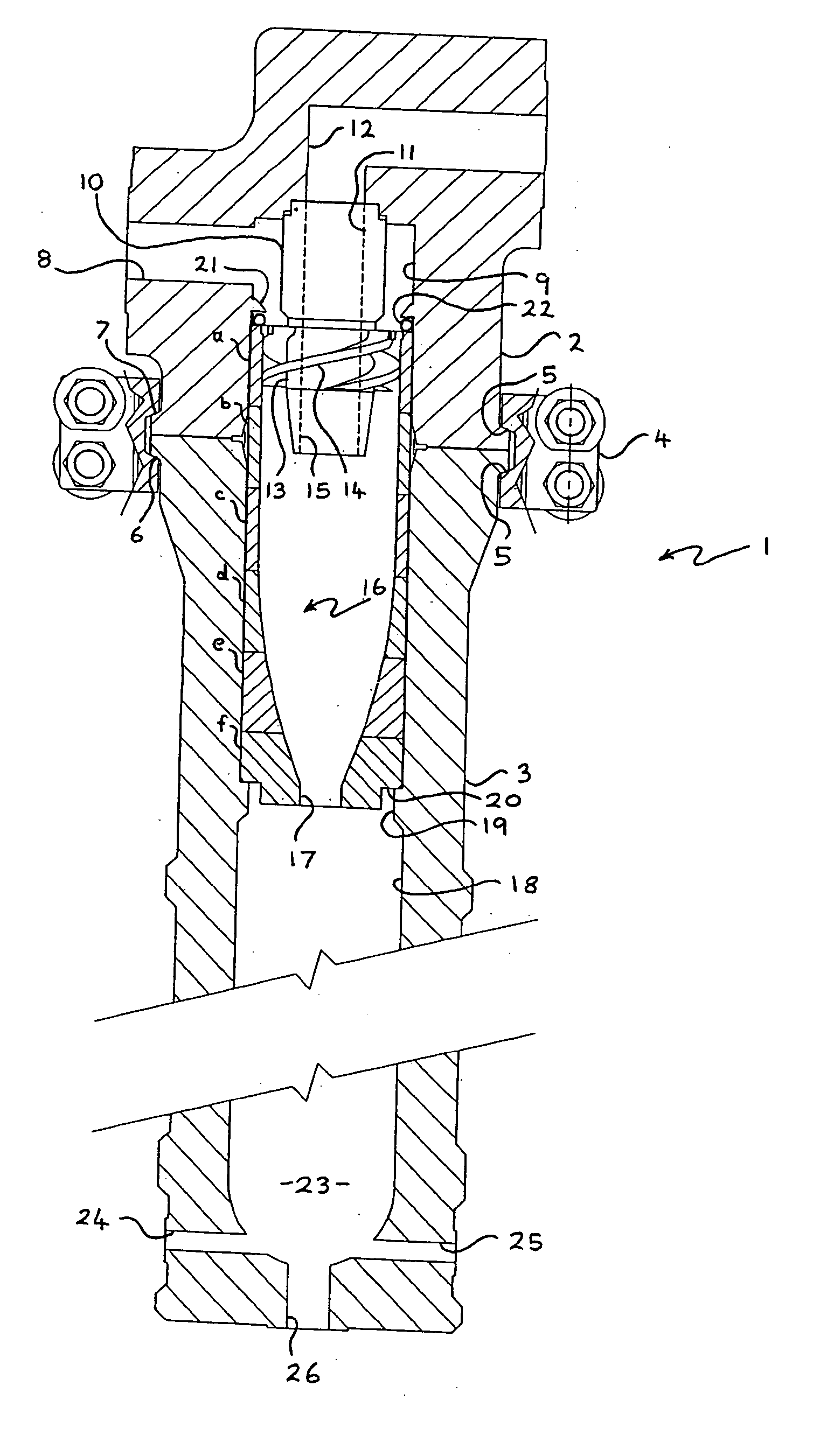

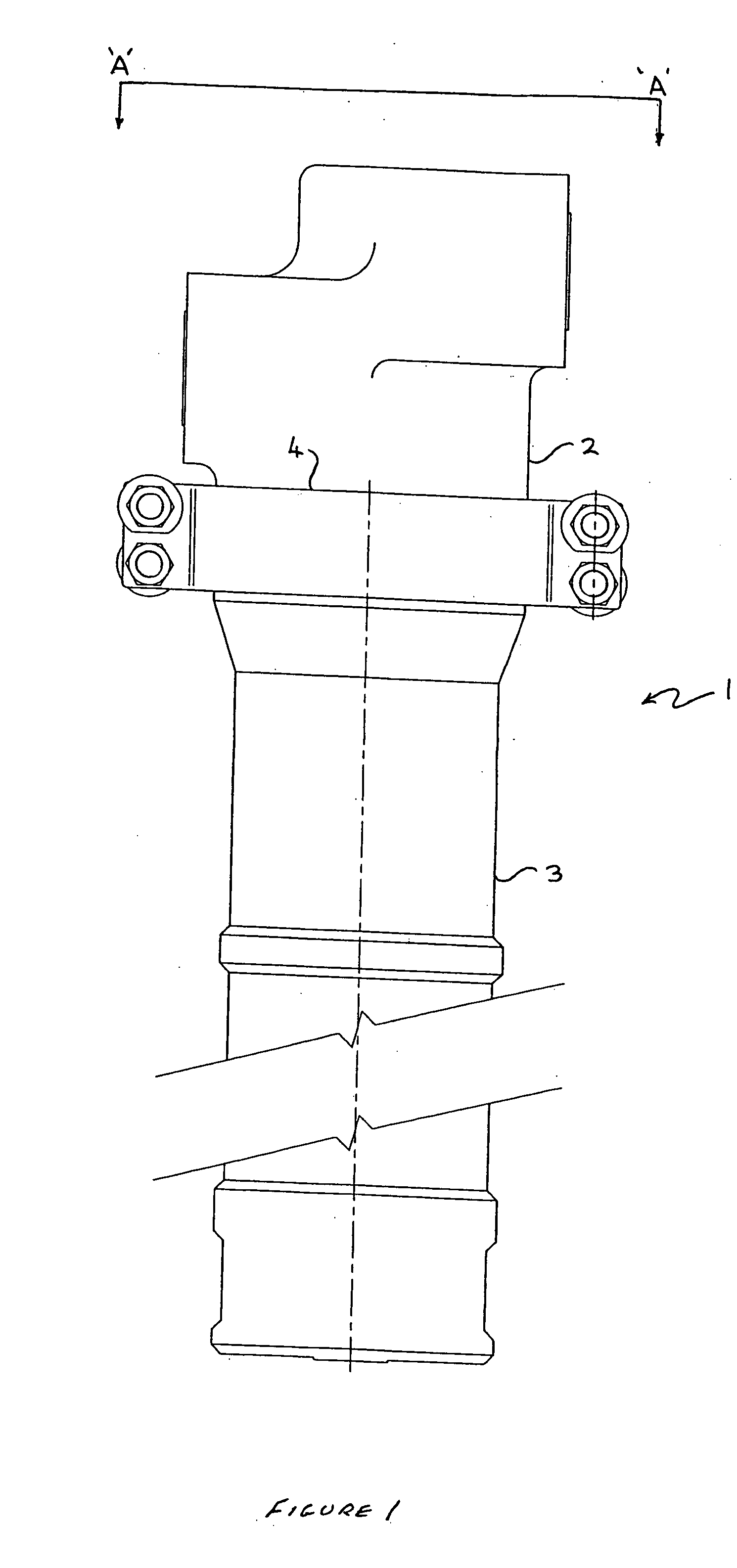

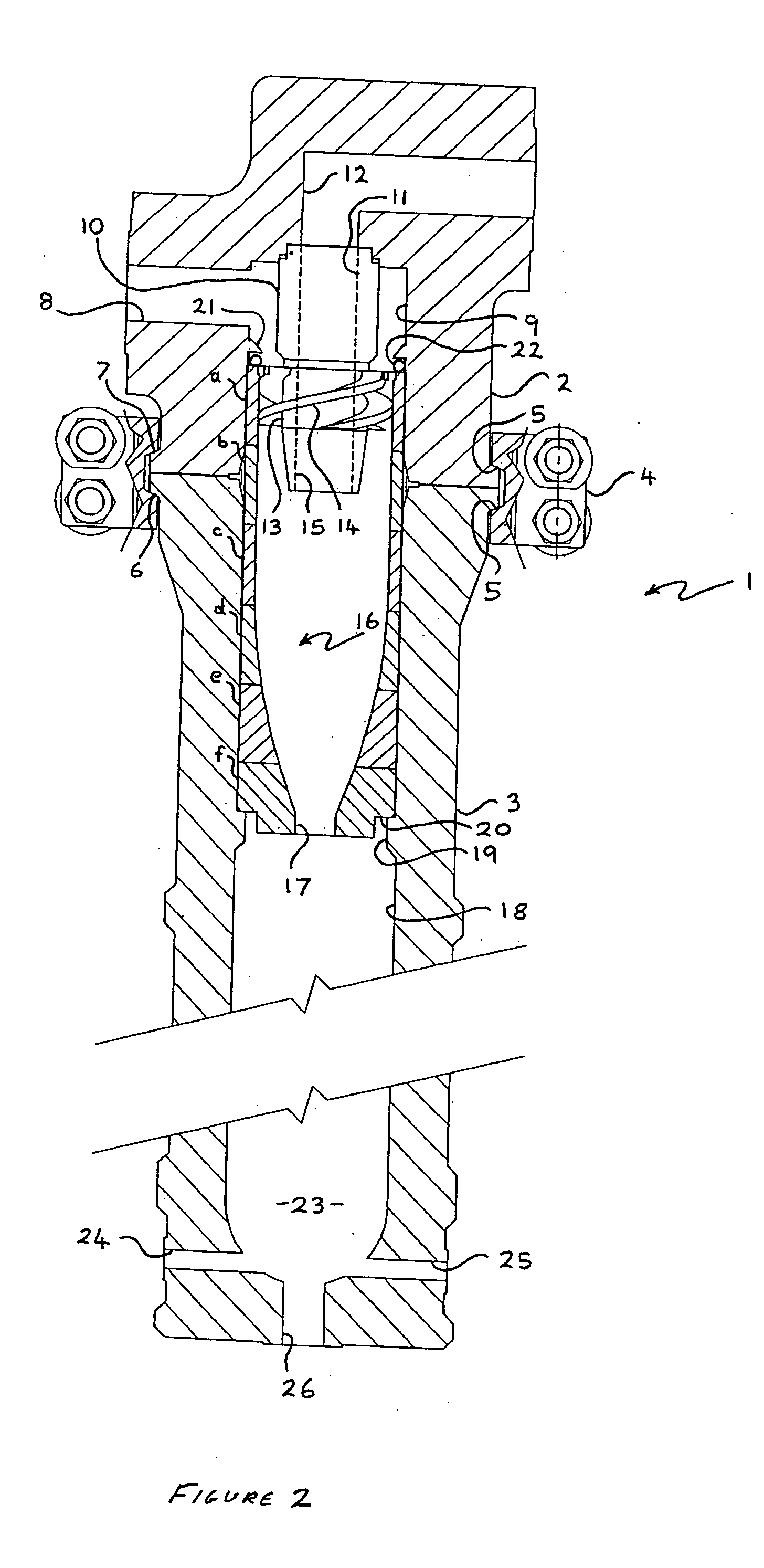

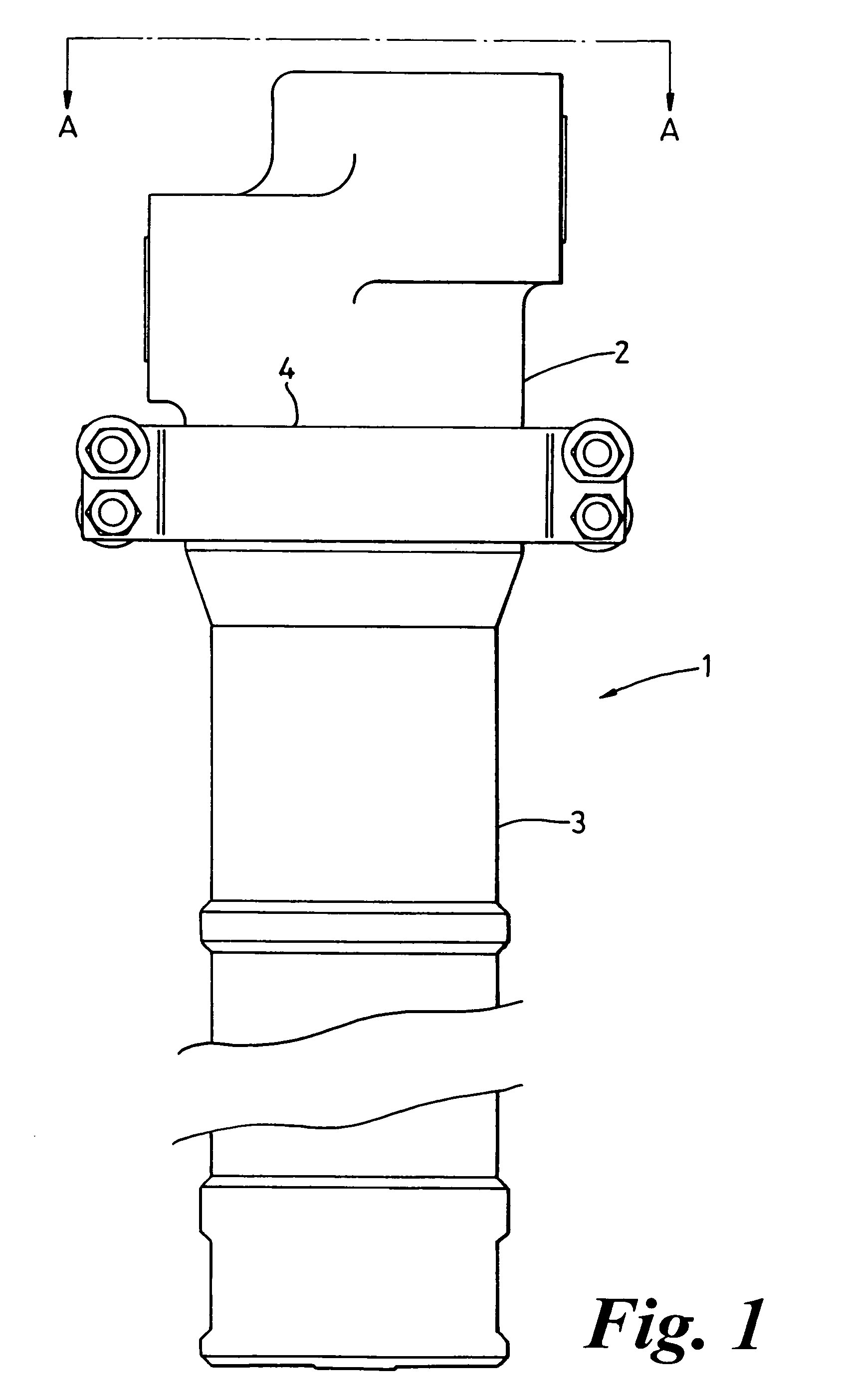

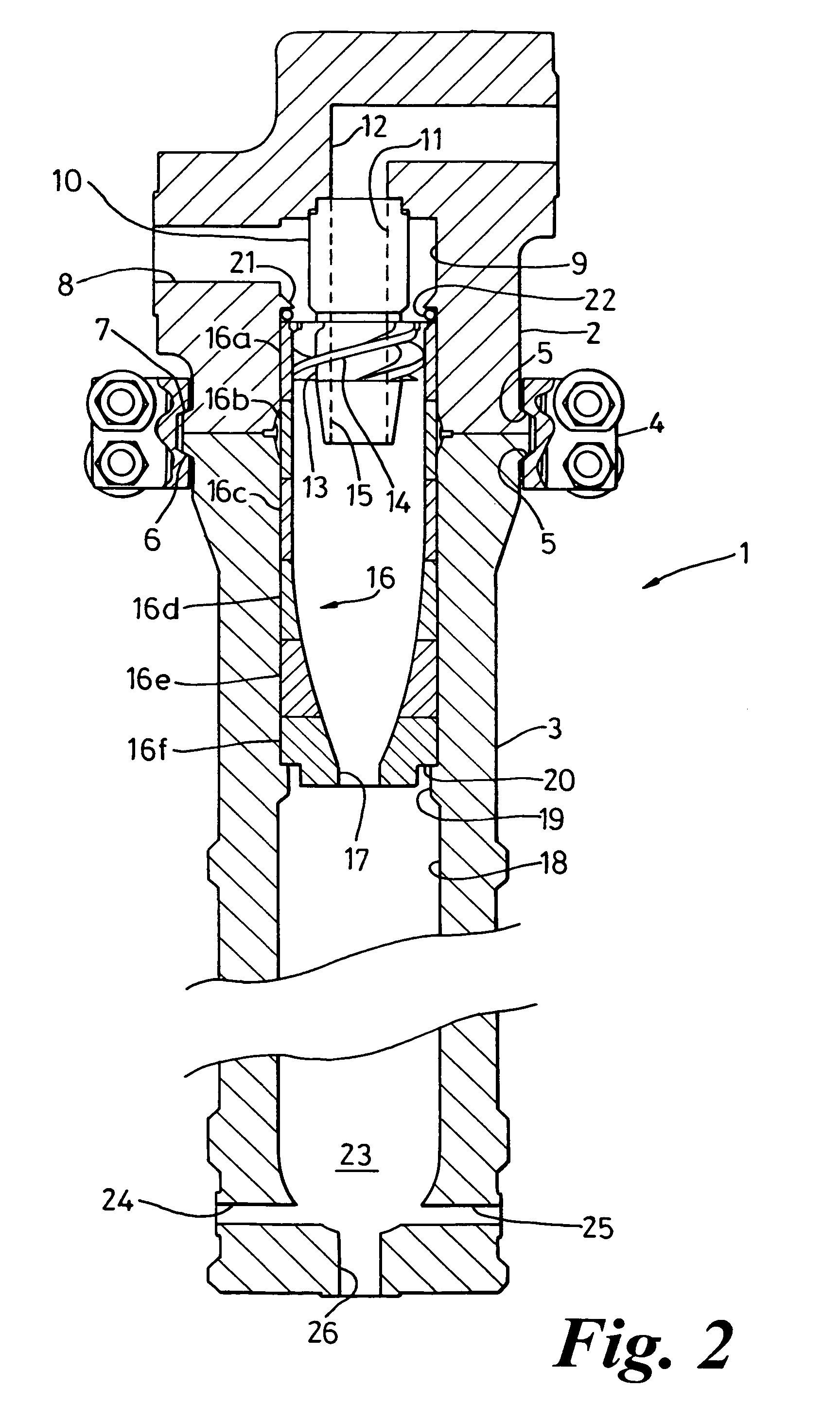

Relating to well head separators

ActiveUS20050236324A1Easy to shapeEconomising on manufacturing costWater/sewage treatment by centrifugal separationReversed direction vortexParticulatesCyclone

Well head hydrocyclone separators are typically used for separating particulates from fluids such as gas, oil and water and mixtures thereof. Well head separators are useful to prevent wear and blocking of choke valves, rupture of piping, damage to instruments and to prevent vessels from filling with particulate materials. In the present invention, the cyclone separator assembly includes an inlet, an overflow outlet and a segmented cyclone separator tube.

Owner:AXSIA SERCK BAKER

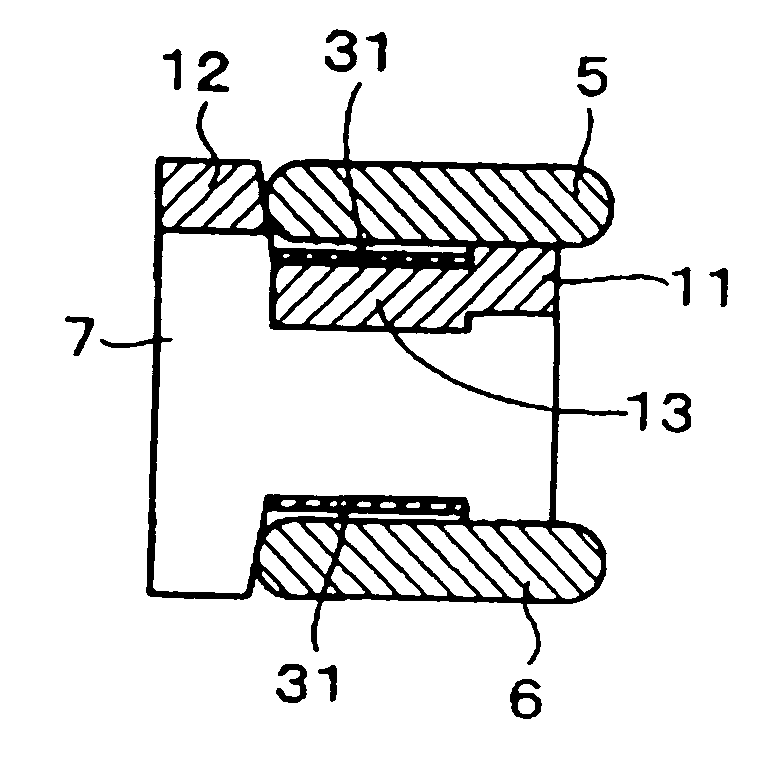

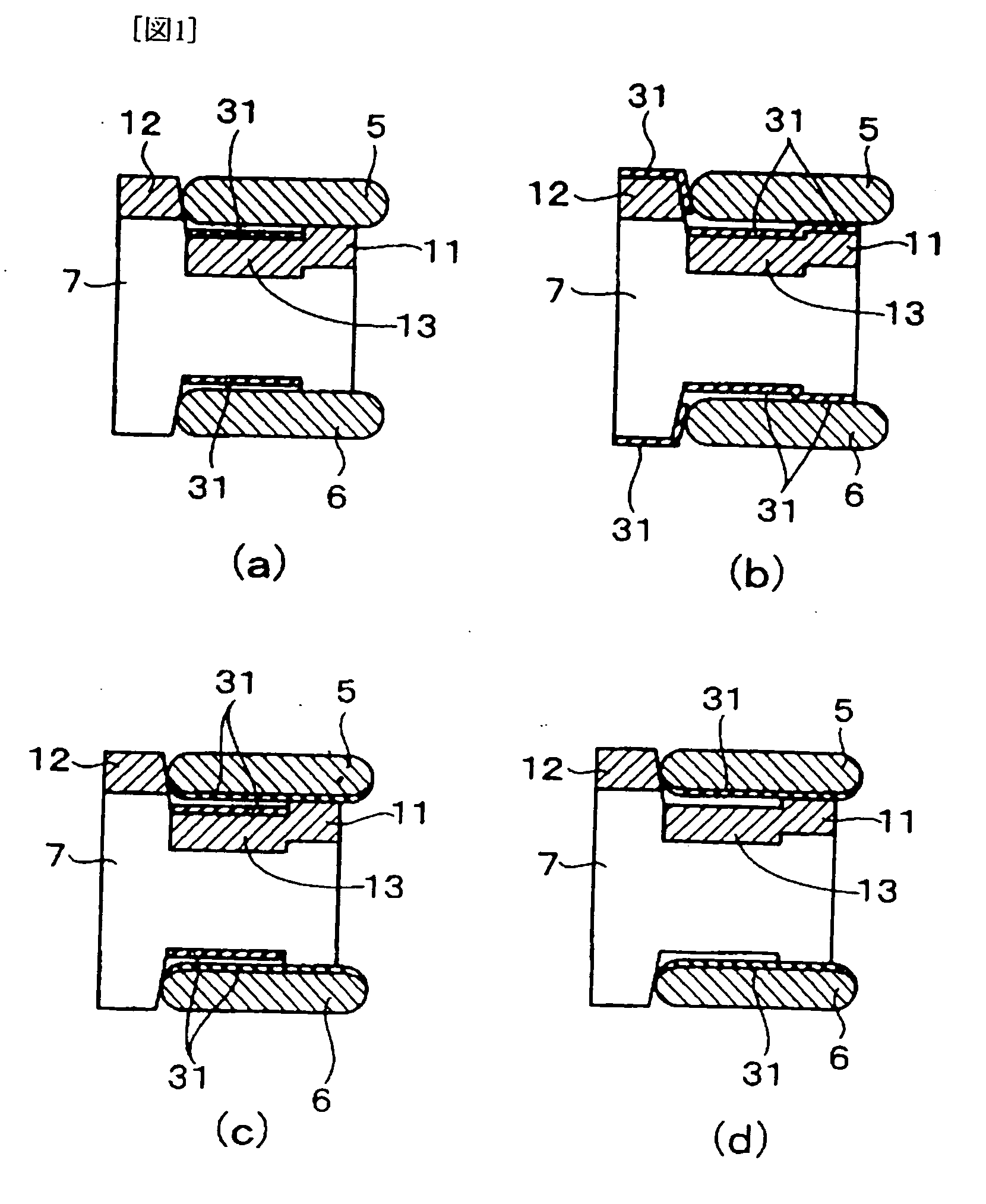

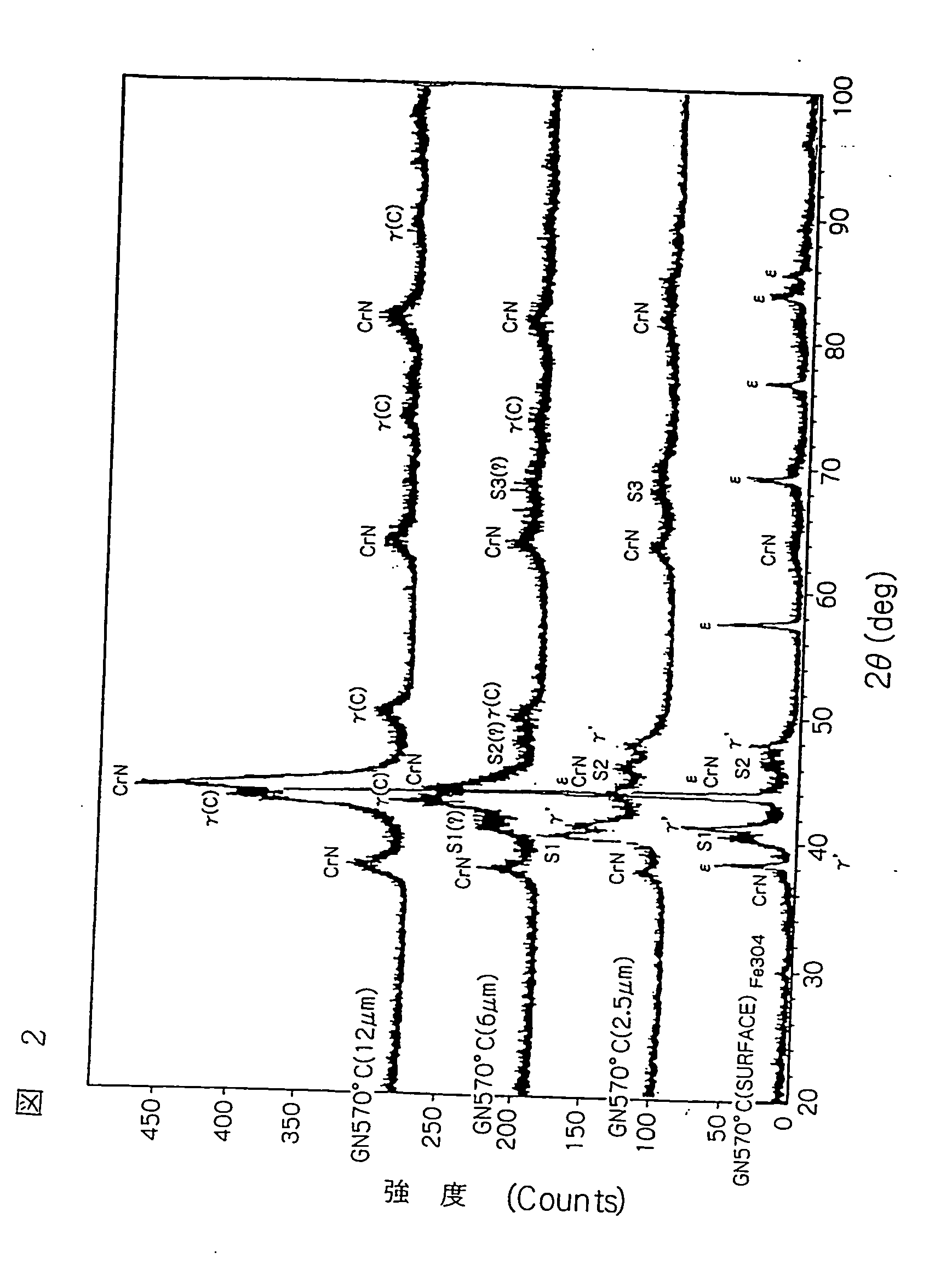

Three piece-combined oil ring

InactiveUS20060061043A1Poor corrosion-resistanceReduce tensionPiston ringsBraking action transmissionSurface layerX-ray

A three-piece combined oil-control ring comprises a pair of upper and lower side rails 222 in the axial direction and a spacer expander 224. The spacer expander is located between the side rails 222, and pushes the side rails from their inner peripheral side to generates the tension of the side rails 222. The ears of the spacer expander made of austenitic stainless steel in contact with inner peripheral surfaces of the side rails, are subjected to gas-nitriding at a temperature of 470° C. or higher to form a 10 to 60 μm thick gas-nitriding surface-layer comprising a phase having peaks at 2θ=40° and 2θ=46° by Cu—K α X-ray diffraction. In addition or alternatively, a resin coating film (31) is formed on at least surfaces of the spacer expander (7) faced to the side surfaces of the side rails or on at least surfaces of the side rails (5,6) faced to the spacer expander (7).

Owner:RIKEN CO LTD

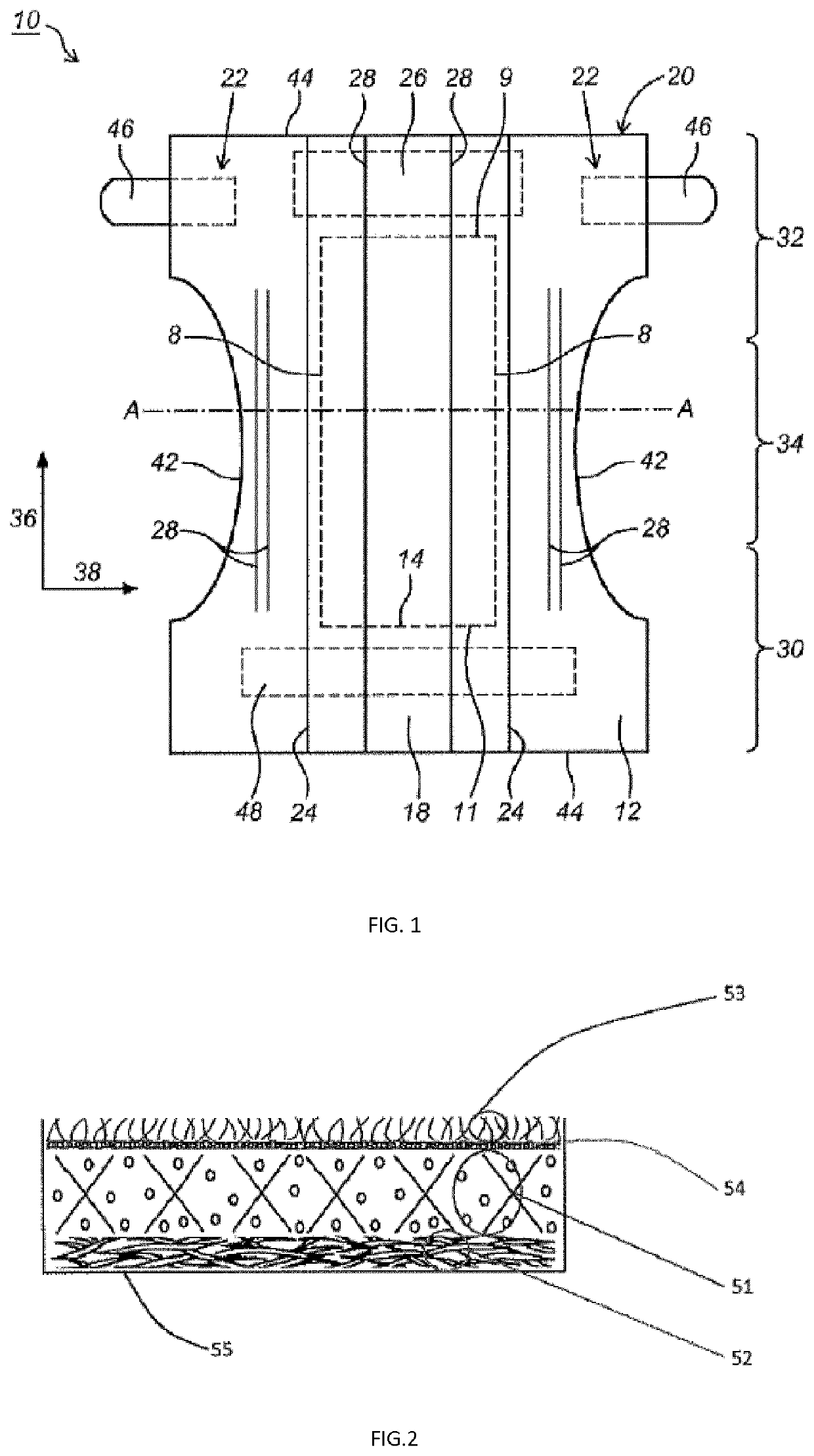

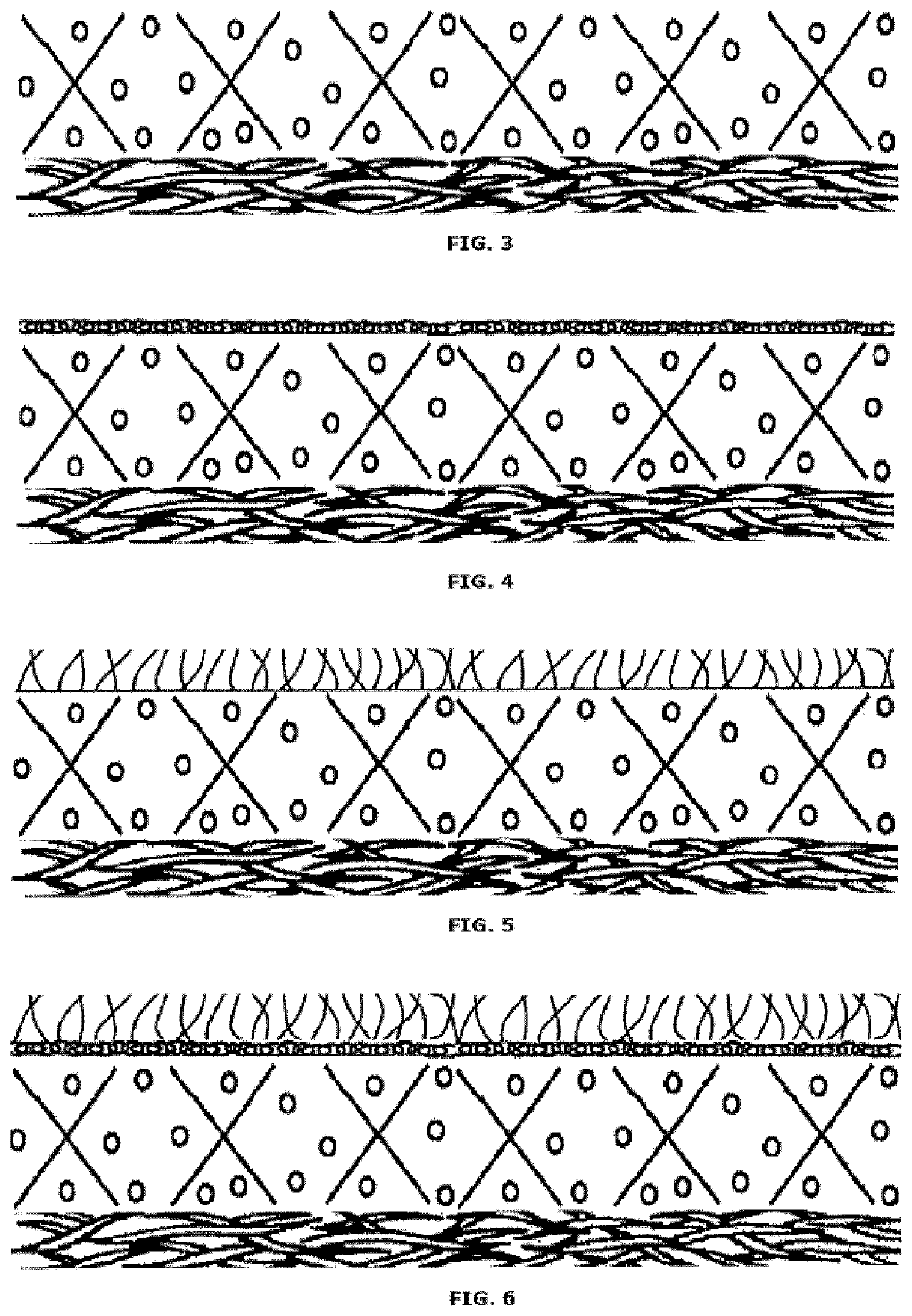

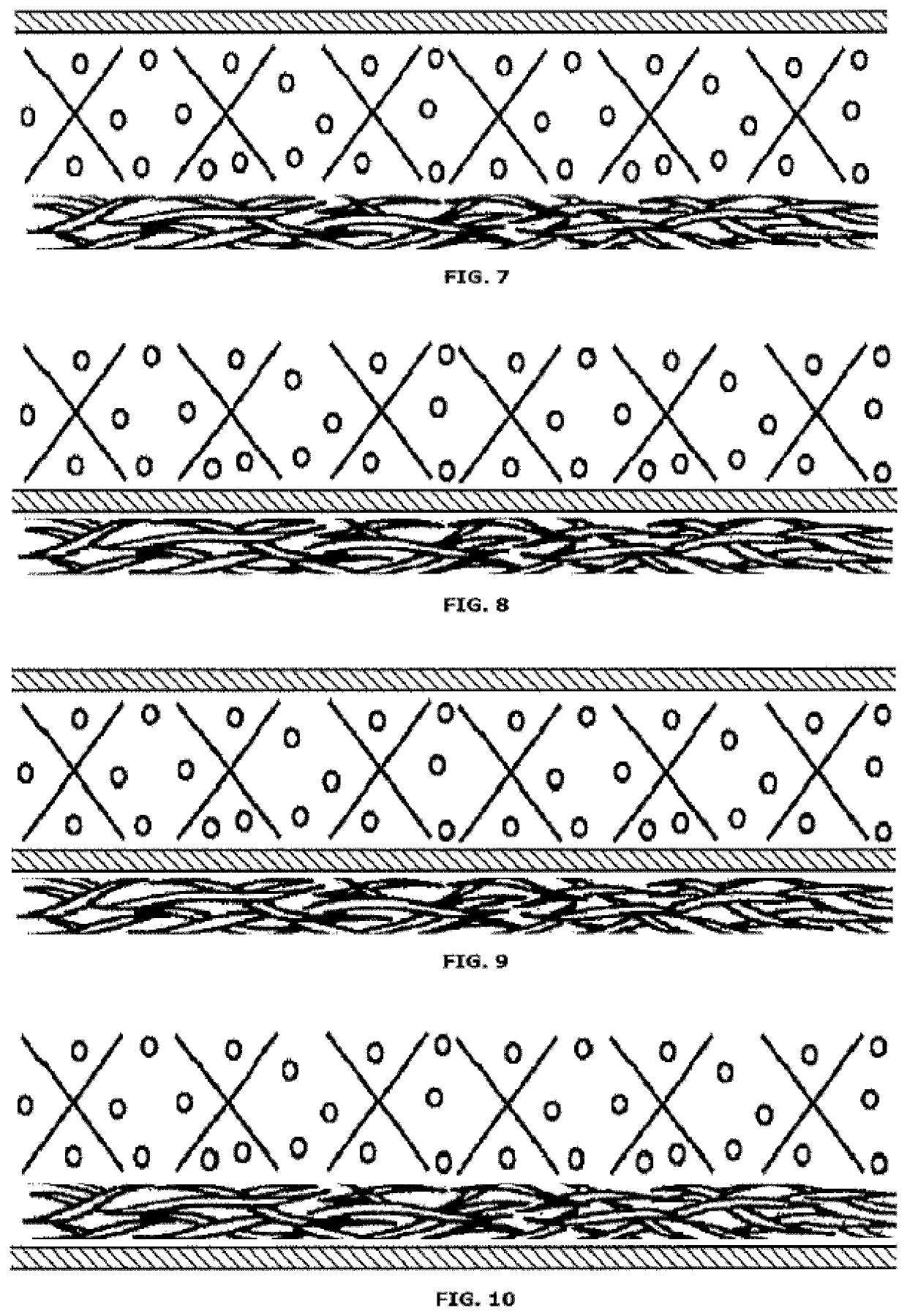

Carpets with improved fuzz-resistance

Tufted carpets bonded with thermoplastic binders and having improved resistance to fuzz formation due to removal of pile yarn filaments from tuft bundles comprise one or more backings, face yarn that forms a pile on one side and stitches on an opposite side, a thermoplastic binder that binds stitches and the backing or backings, and an organic polymer that bonds filaments of the stitches. Processes for making carpets comprise applying to a stitched side of a tufted backing a liquid stitch bind composition comprising an organic polymer component, removing a liquid component of the composition to bond filaments of the stitches and bonding stitches and one or more backings with a thermoplastic binder that is melted or applied as a melt in contact with the stitched side and the backing or backings and solidified.

Owner:PROPEX OPERATING

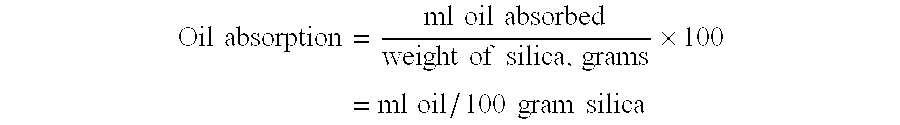

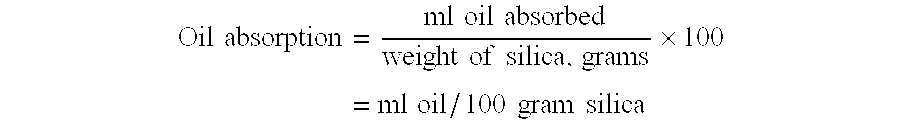

High-cleaning silica materials made via product morphology control under high shear conditions

InactiveUS20070224133A1Desirable abrasiveIncrease brightnessCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

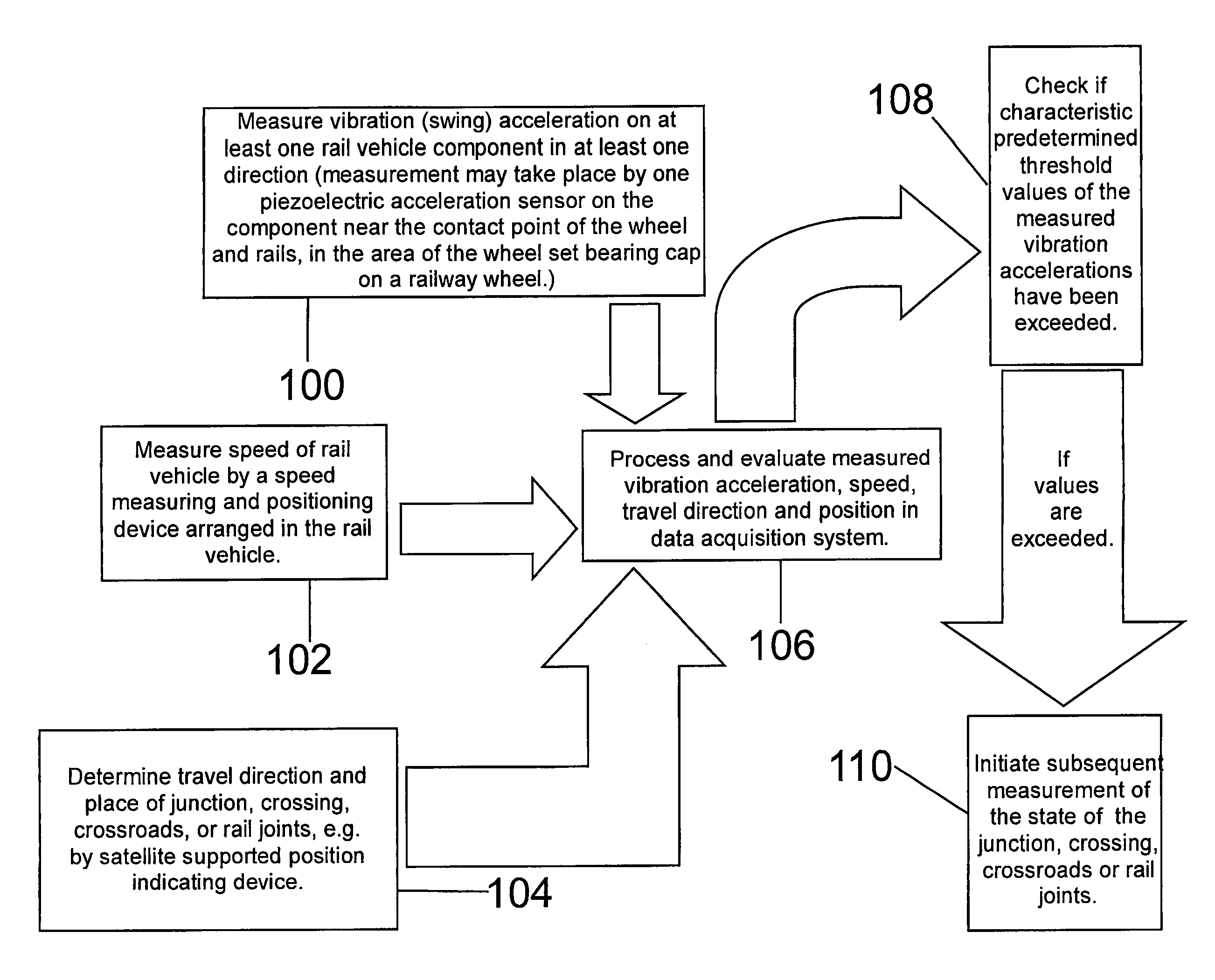

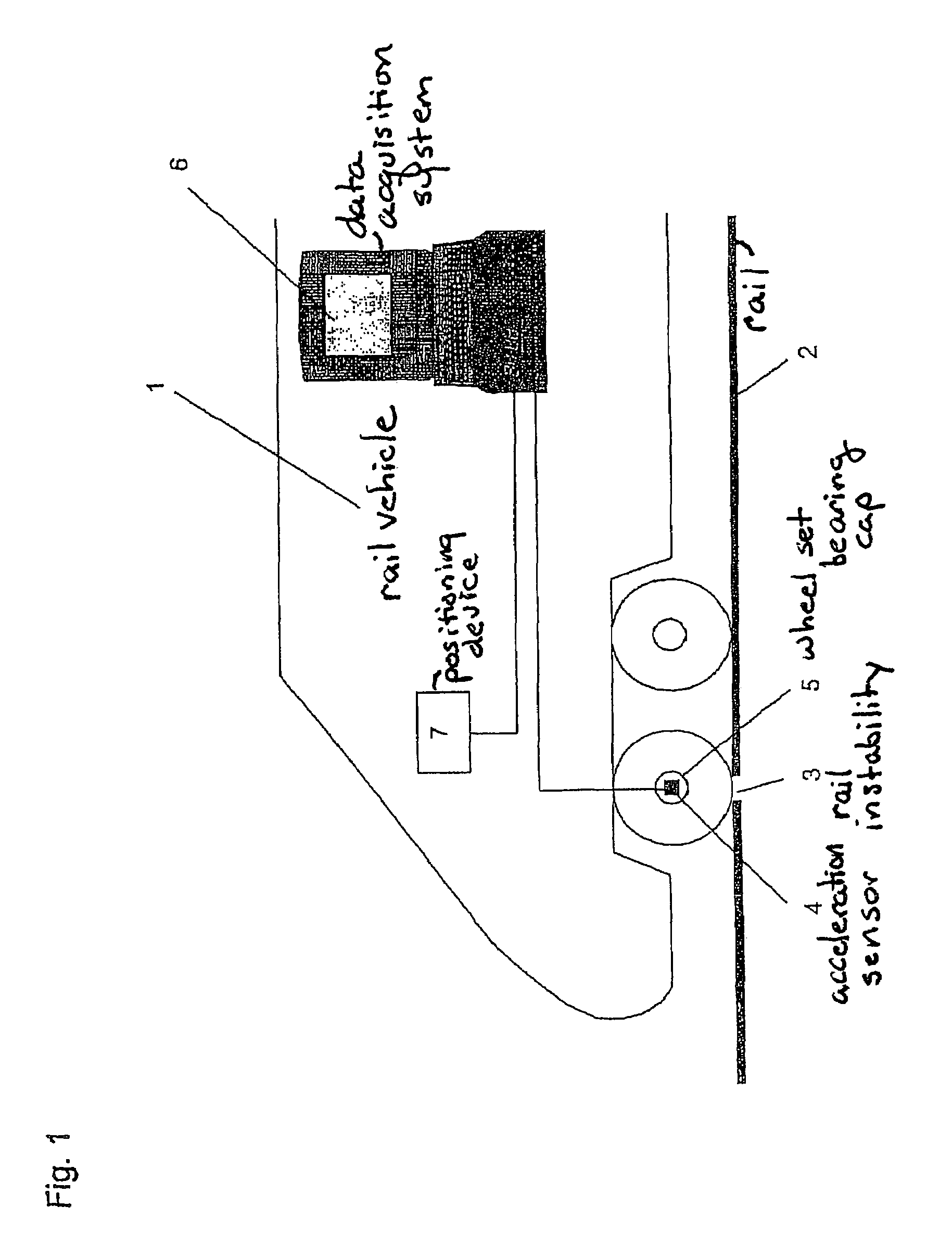

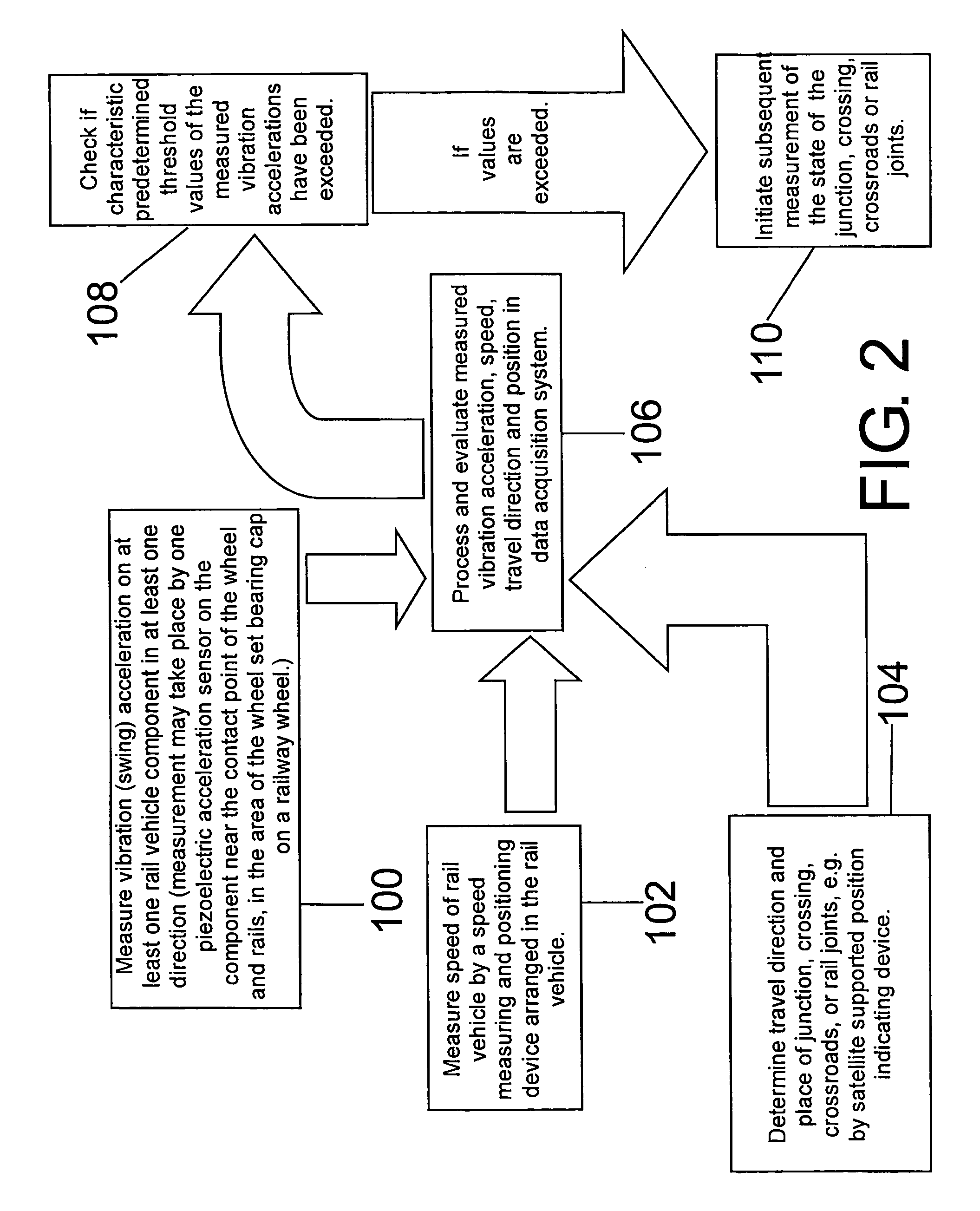

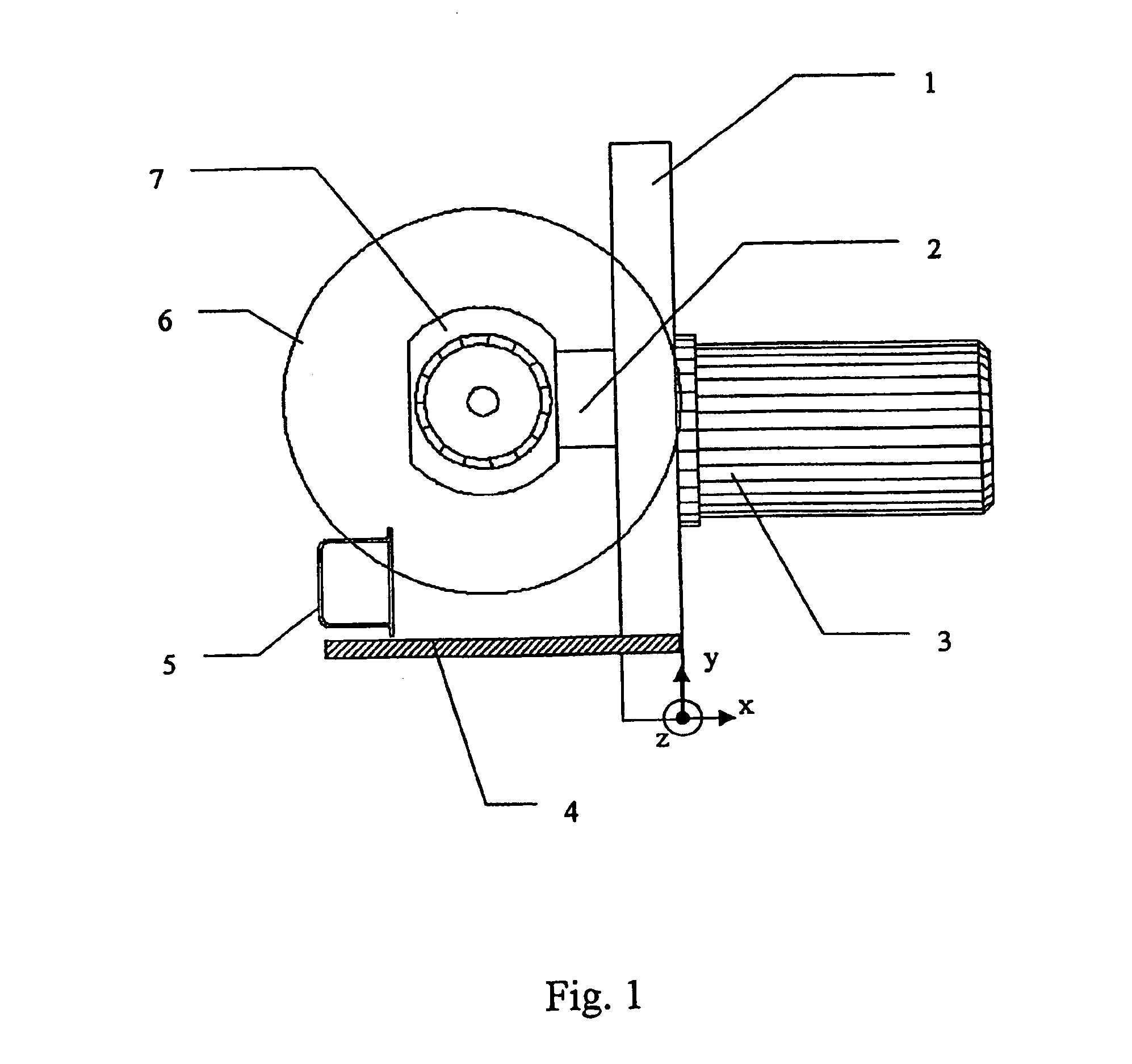

Diagnosis and state monitoring of junctions, crossings, crossroads or rail joints by means of a rail vehicle

ActiveUS7539596B2Accurate directionPromote and accelerate advancingPlug gaugesDigital computer detailsAutomotive engineeringCondition monitoring

A method and a device for diagnosis and state monitoring of a wear and functional state of a junction, a crossing, a crossroads, rail joints, and / or track nonuniformities of a rail traffic path made of several tracks measures and stores swing acceleration in at least one direction when overtaking a rail vehicle on a junction, crossings or crossroads, in addition to rail joints or track nonuniformities on at least one rail vehicle component, the swing acceleration being produced on the rail vehicle component when overtaking the rail vehicle at the junction, crossing or crossroads, rail joints, track nonuniformites. The method also measures and stores the rail vehicle speed and determines and stores the travel direction and the place of the junction, crossing or crossroads, rail joints, track nonuniformities, carries out a control as to whether characteristic, predetermined threshold values of the measured swing accelerations have been exceeded.

Owner:DEUTSCHE BAHN

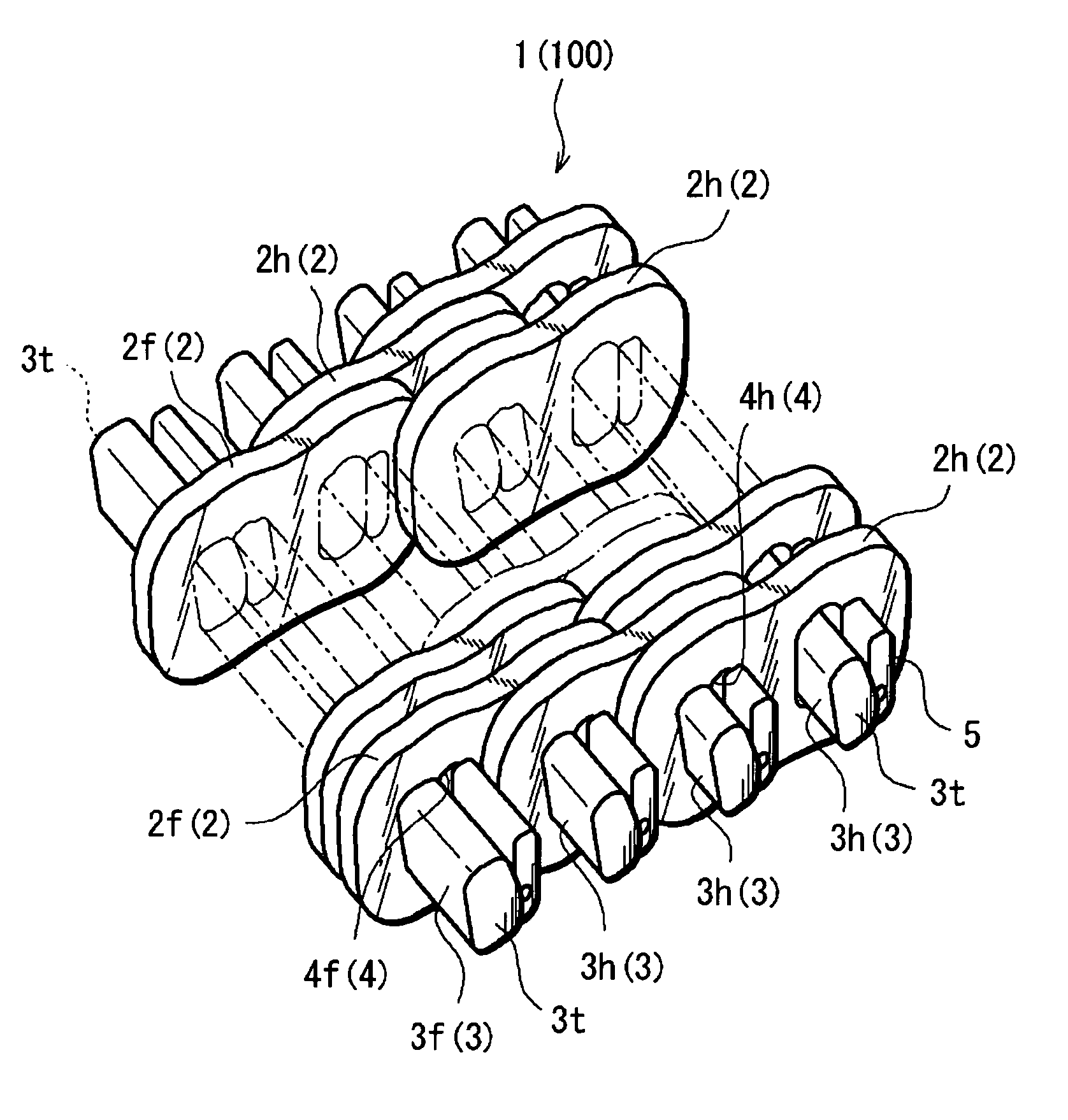

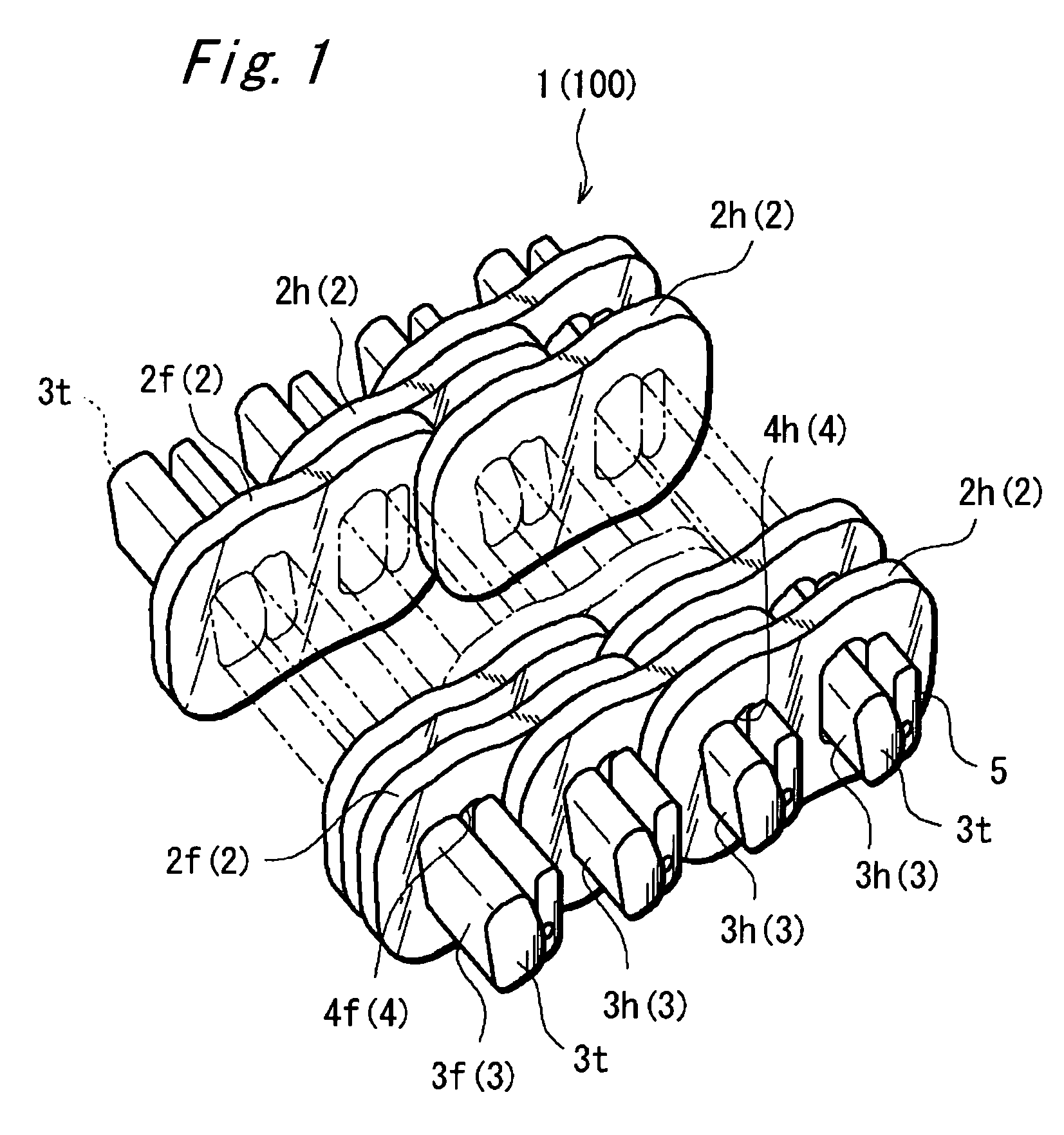

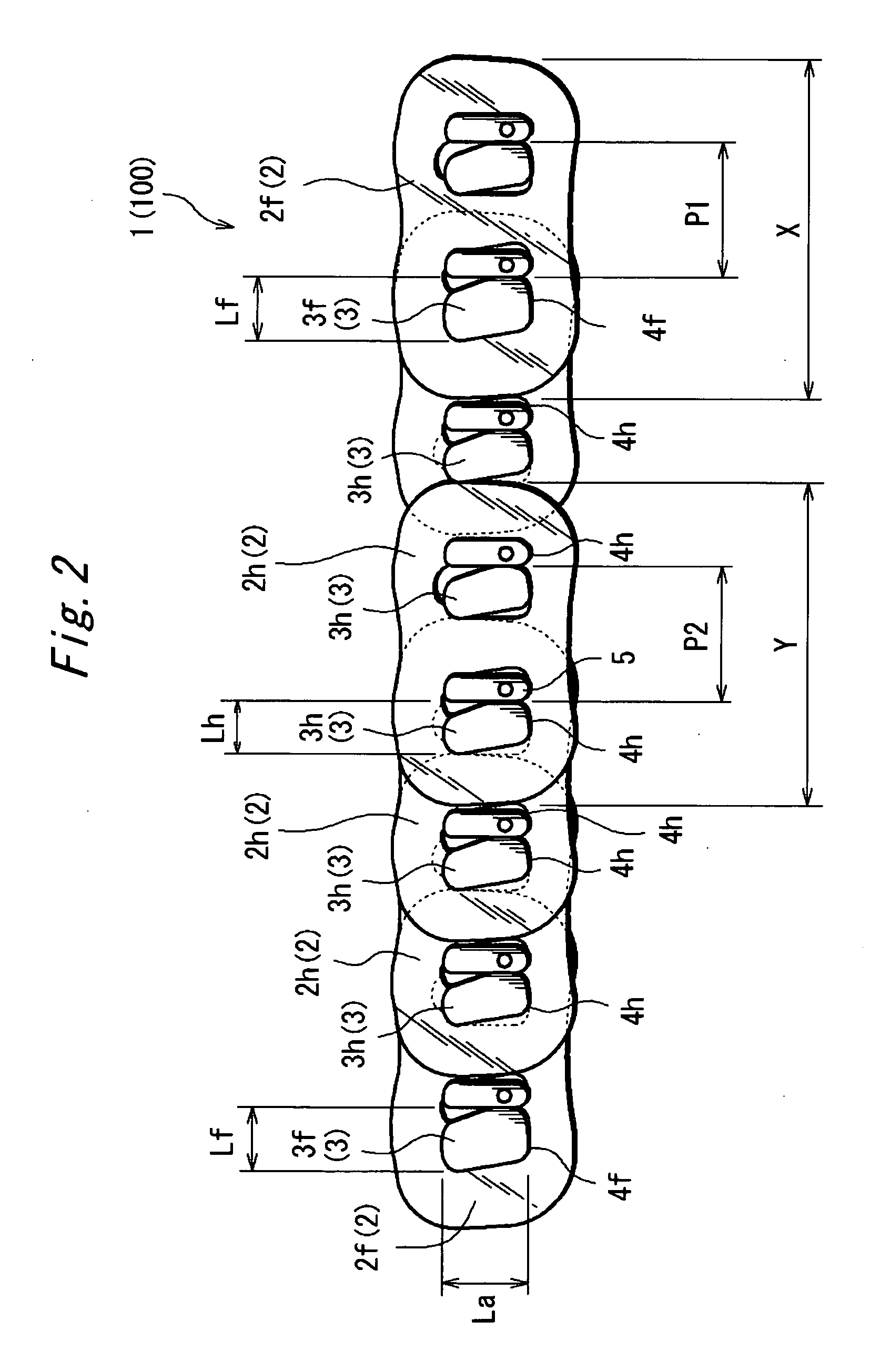

Power transmission chain and power transmission assembly using the same

An object of the invention is to provide a power transmission chain capable of effectively reducing noises and a power transmission assembly using the same. In the power transmission chain including plural links each possessing through-holes and plural pins inserted through the through-holes for interconnecting the plural links, all the plural pins substantially have the same longitudinal length while the plural pins include plural types of pins which have mutually different rigidities against force acting in the pin longitudinal direction. Furthermore, a locus of contact position between the pin and a strip is defined by an involute of a circle. The pins and strips are combined to form two or more types of pairs which provide the involutes of base circles having different radii.

Owner:JTEKT CORP

High-cleaning, low abrasion, high brightness silica materials for dentrifices

InactiveUS7270803B1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethSilica gel

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

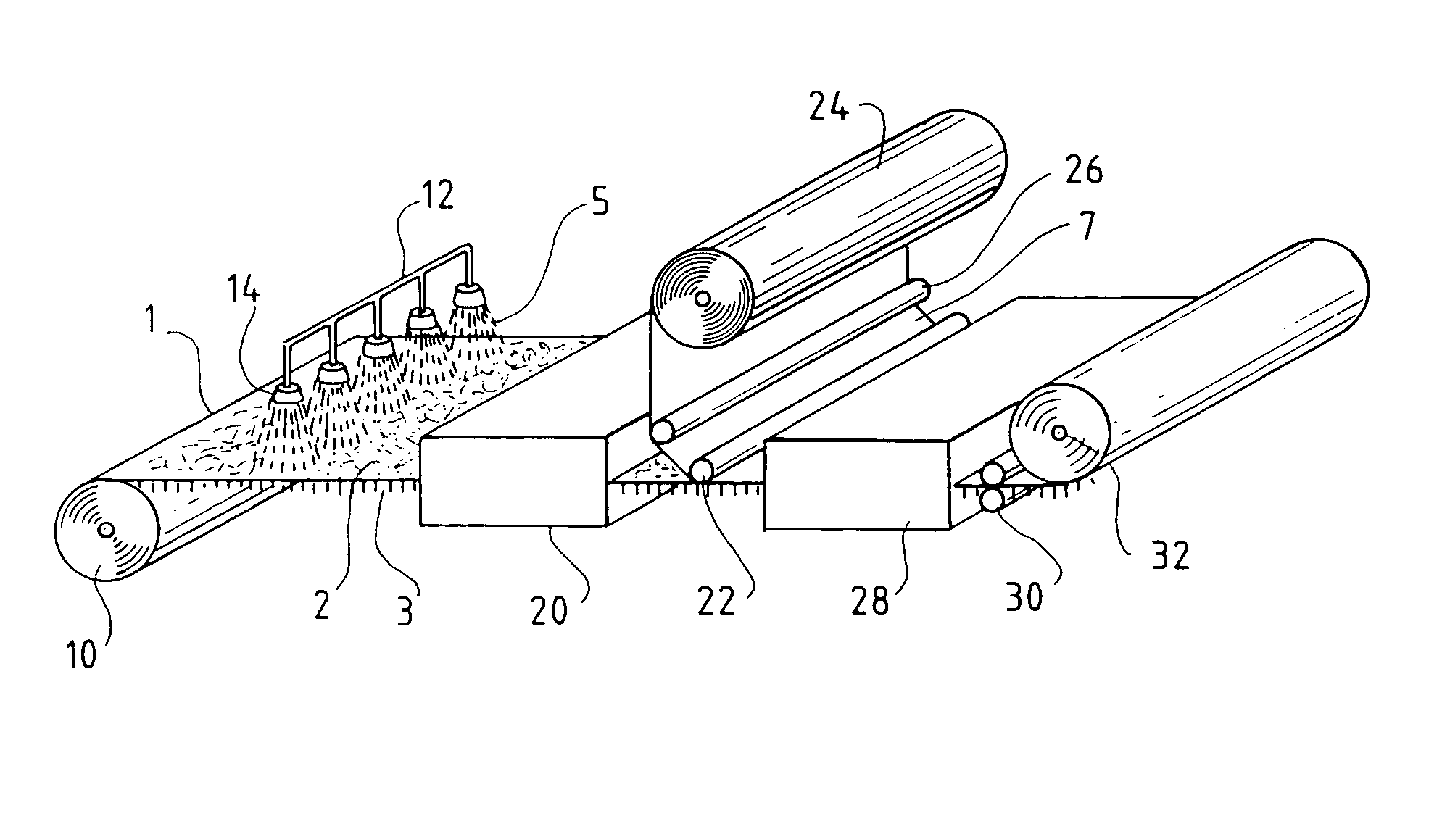

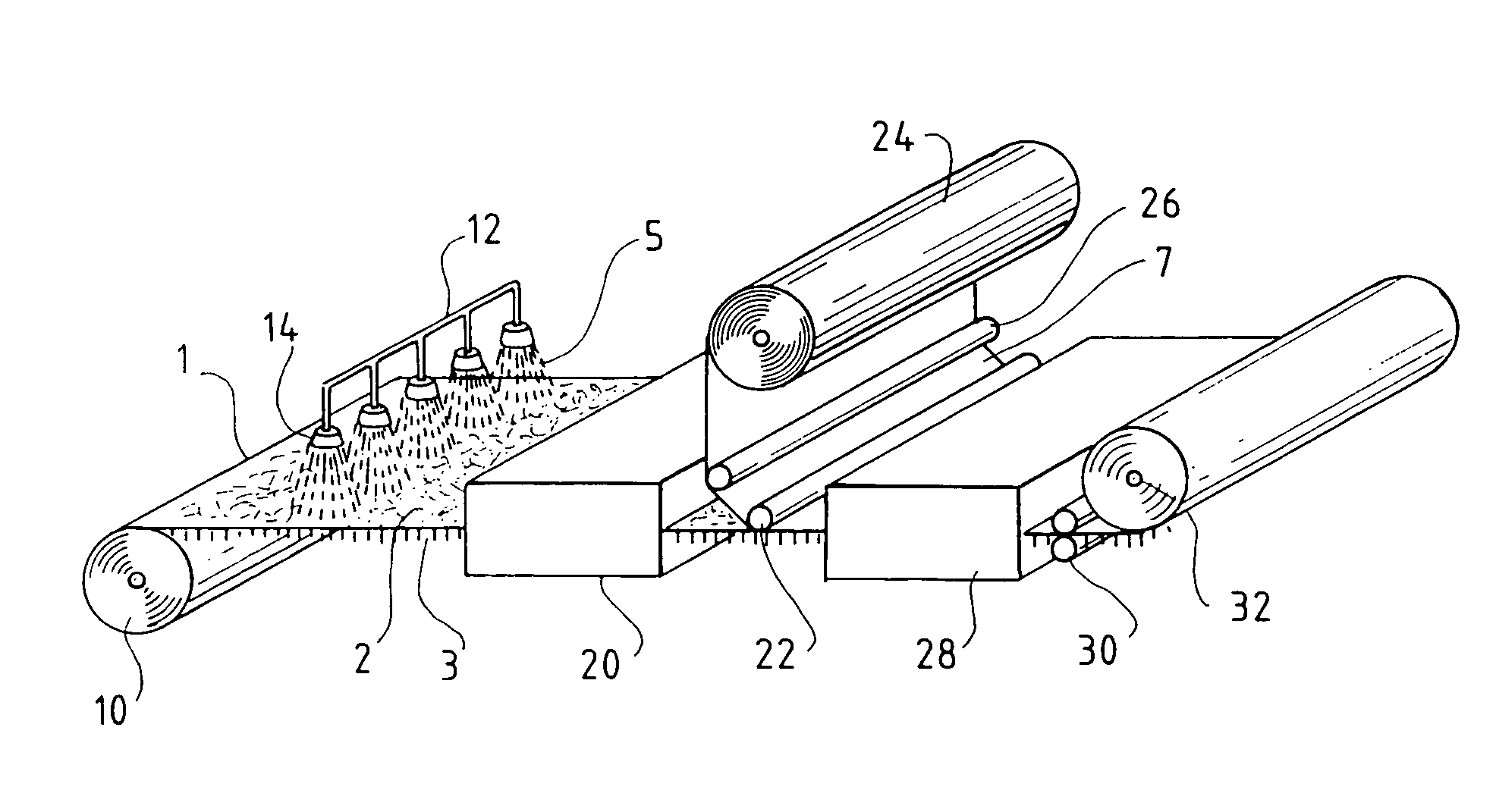

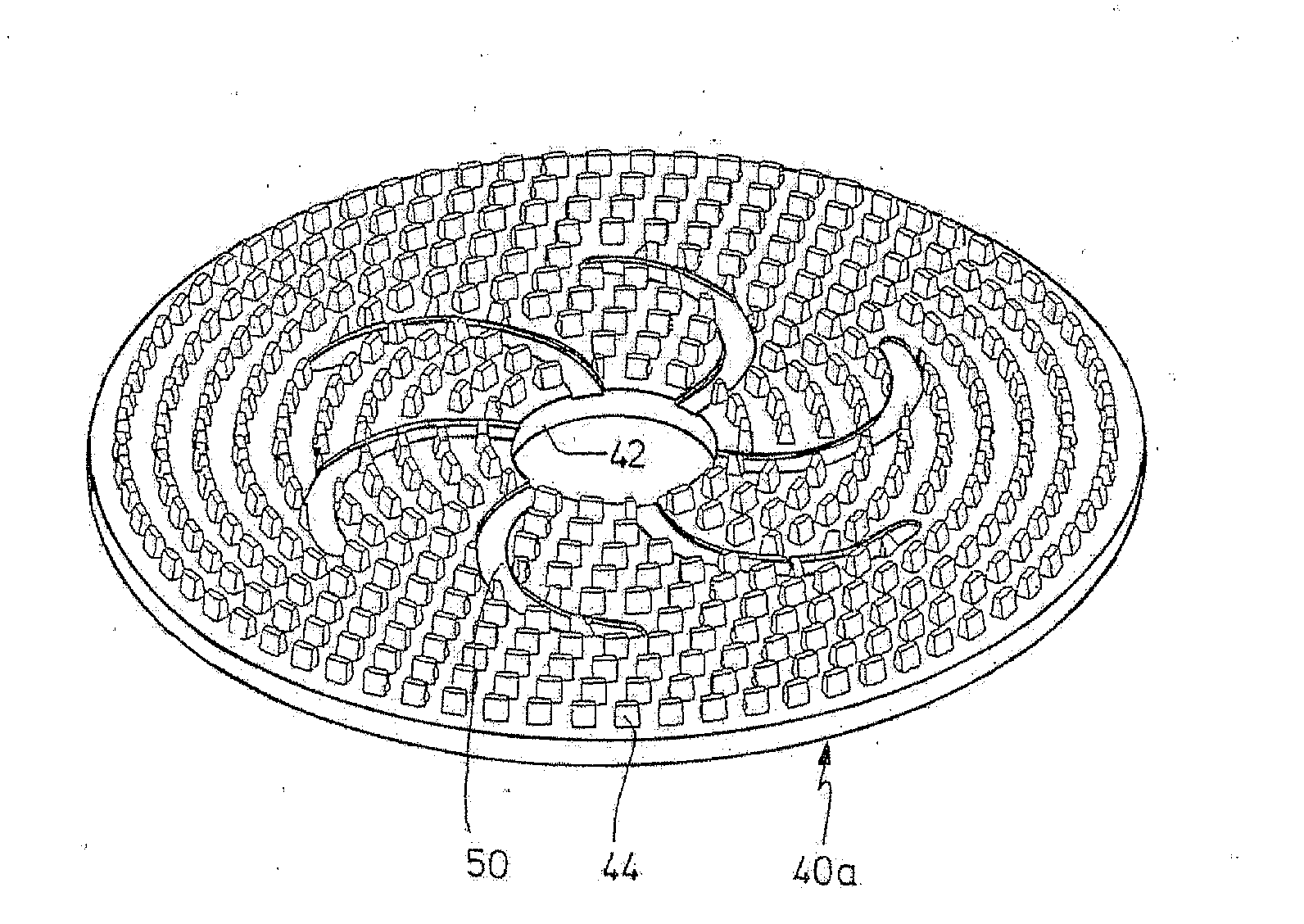

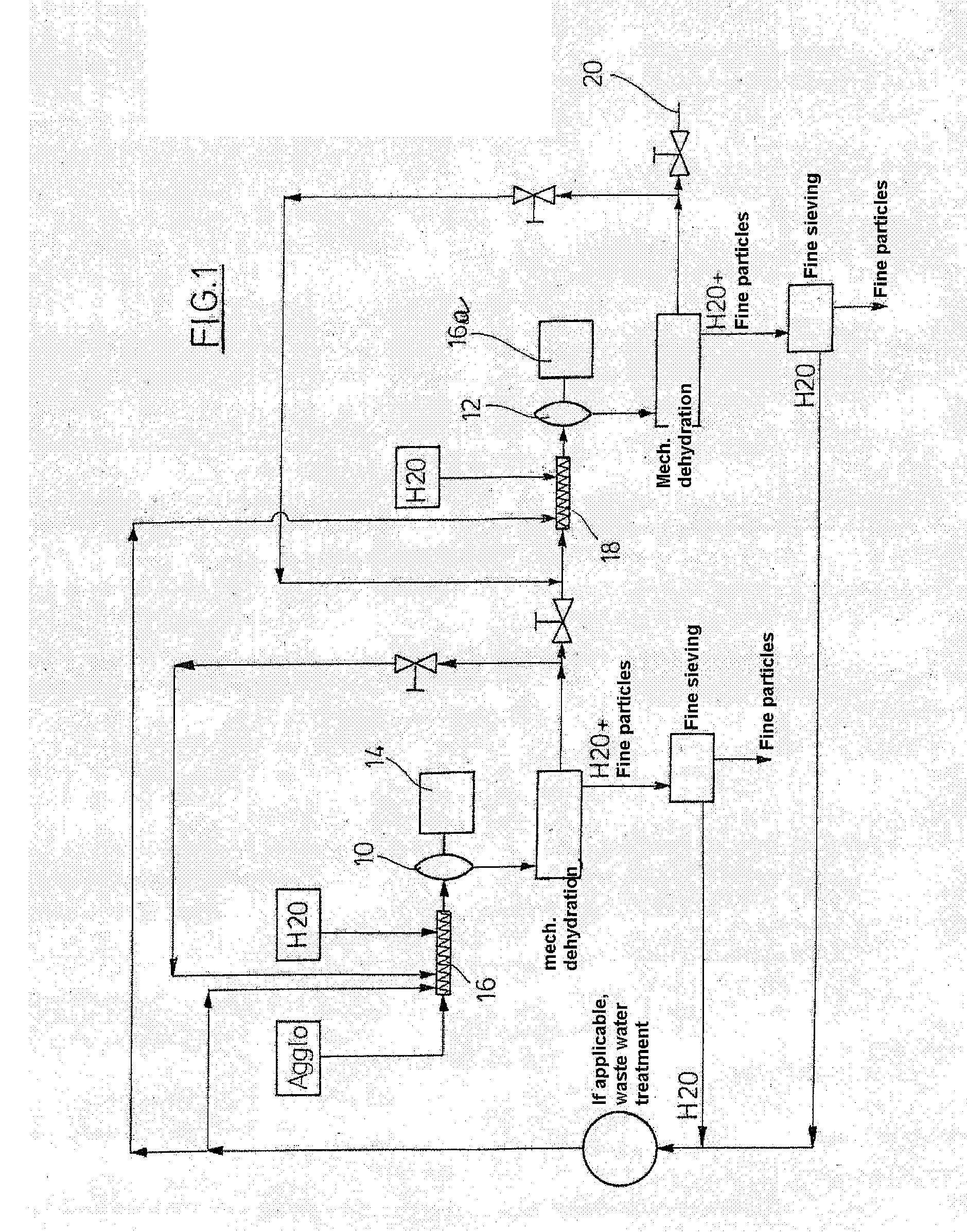

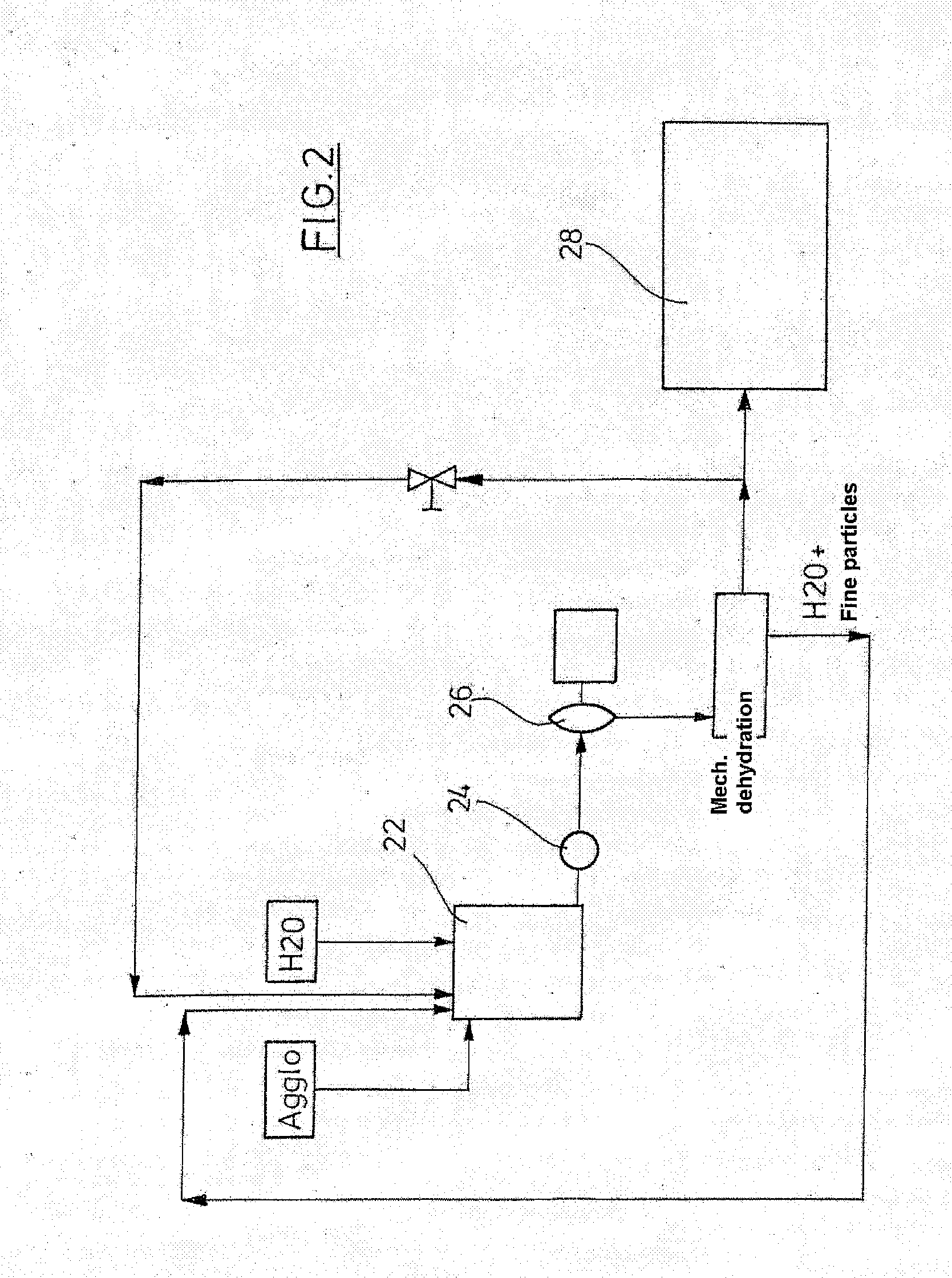

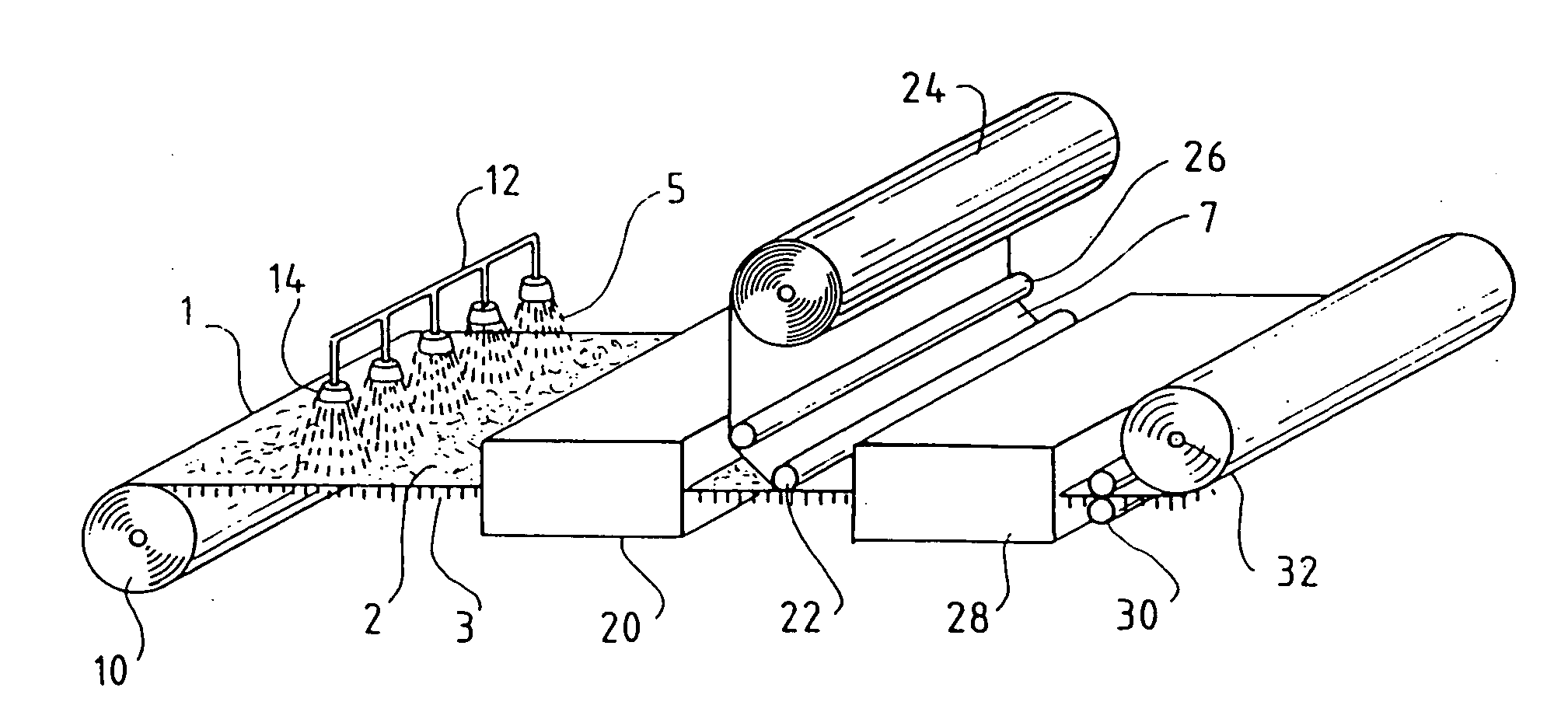

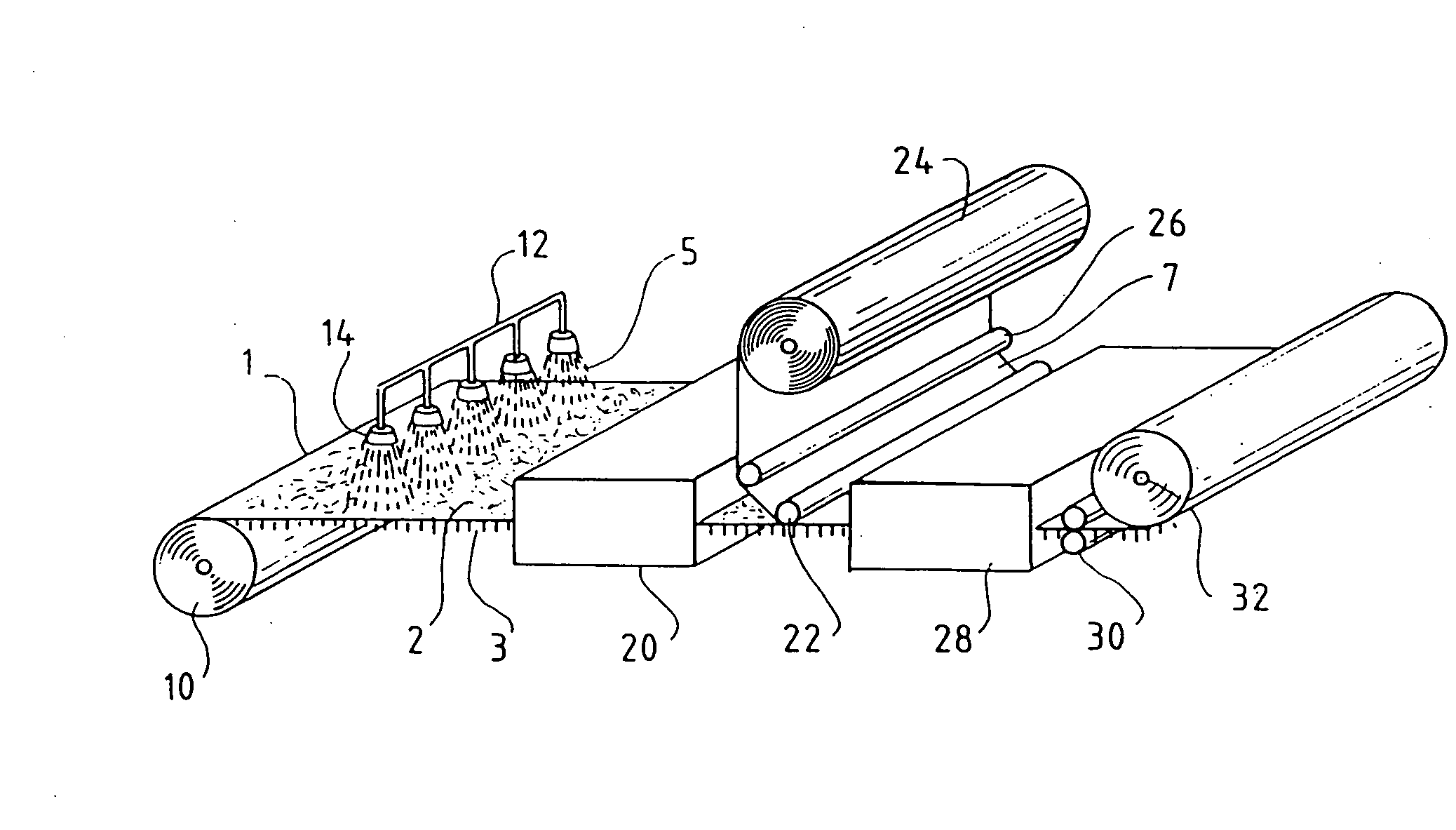

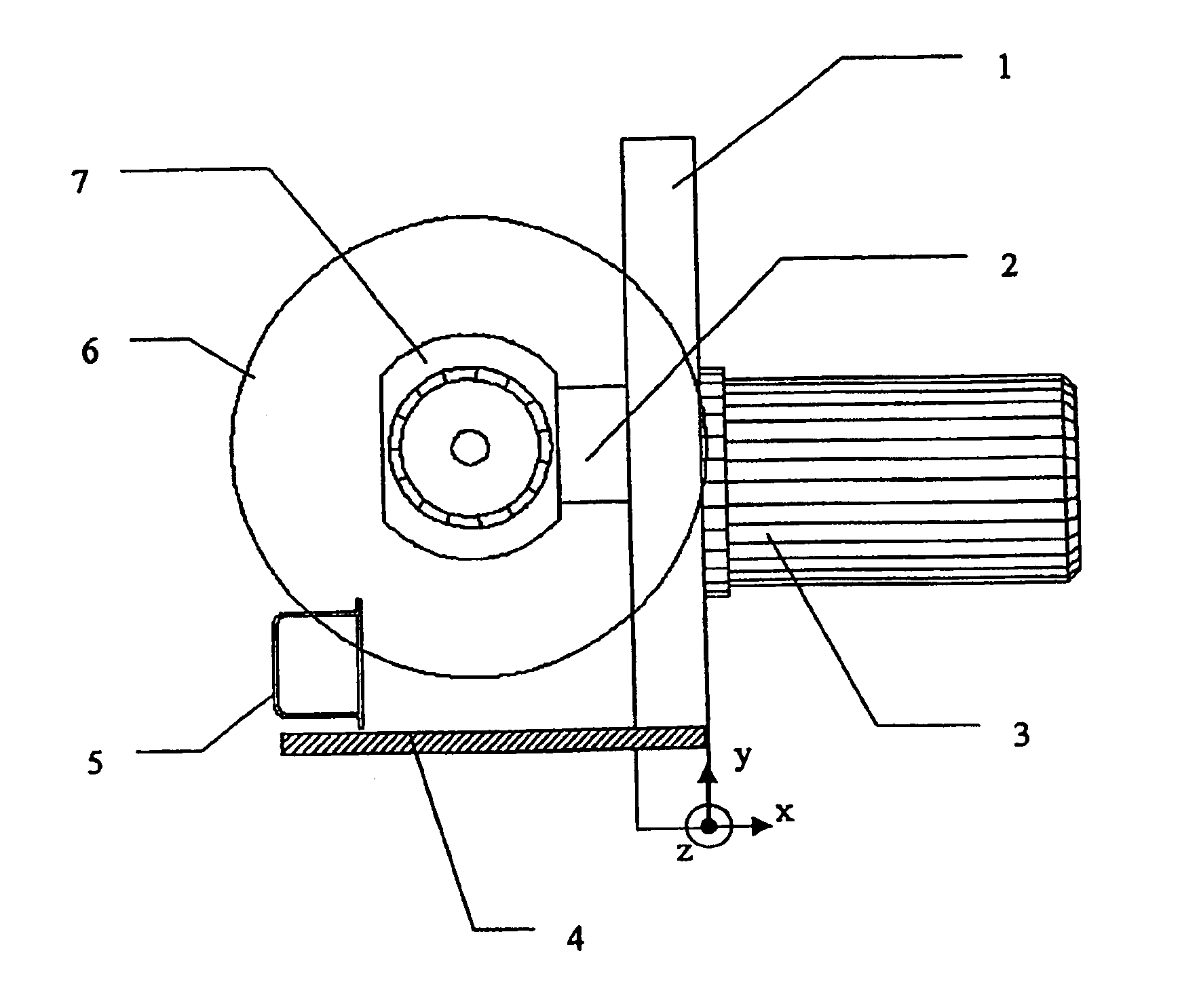

Method for recycling all waste plastics in particular mixed plastics

ActiveUS20100155979A1Small distanceEasy to separateArtificial filament recoverySolid separationEnvironmental engineeringAgglomerate

A method for the recycling of all types of waste plastic, in particular mixed plastic (MP), in which compactate, in particular agglomerate, is ground from flakes or other plastic parts in at least one refiner stage in the presence of water, from which fine particles are removed from the ground material emerging from the refiner stage with the process water, the remaining ground material is washed and / or mechanically dehydrated and dried or the dehydrated ground material is again ground in another refiner stage in the presence of water and then dehydrated and dried, wherein the grinding of the compactate is performed in at least one refiner stage using a disk refiner (toothed disk refiner), the disks of which have engaging teeth, which are arranged separated on concentric circles, wherein there is a hole between neighboring teeth of a circle and the holes of a circle are each big enough that the particles to be ground or ground up to that point can pass through freely.

Owner:CVP CLEAN VALUE PLASTICS GMBH

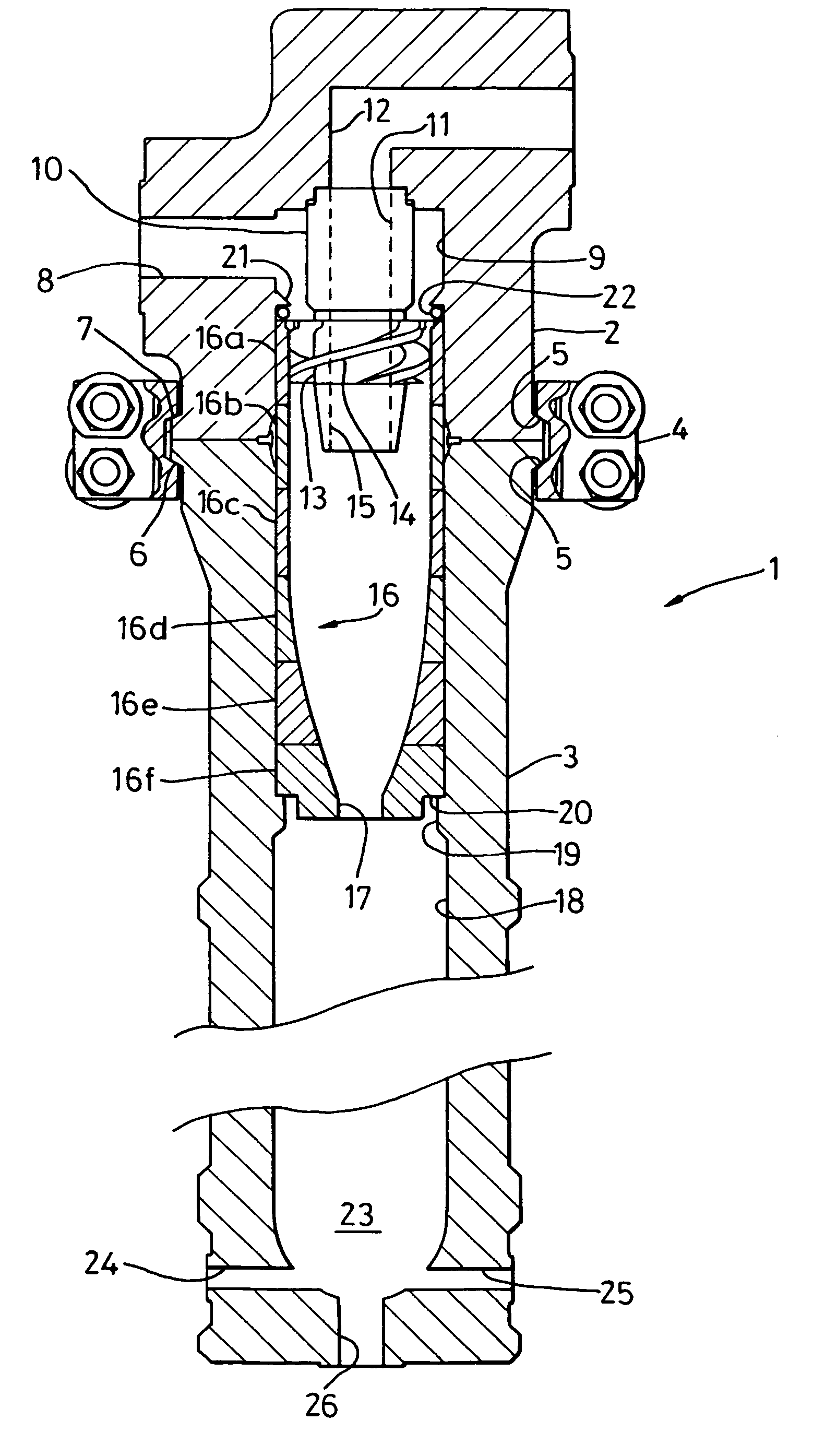

Relating to well head separators

ActiveUS7635430B2Easy to shapeEasy to solveWater/sewage treatment by centrifugal separationReversed direction vortexCycloneParticulates

Well head hydrocyclone separators are typically used for separating particulates from fluids such as gas, oil and water and mixtures thereof. Well head separators are useful to prevent wear and blocking of choke valves, rupture of piping, damage to instruments and to prevent vessels from filling with particulate materials. In the present invention, the cyclone separator assembly includes an inlet, an overflow outlet and a segmented cyclone separator tube.

Owner:AXSIA SERCK BAKER

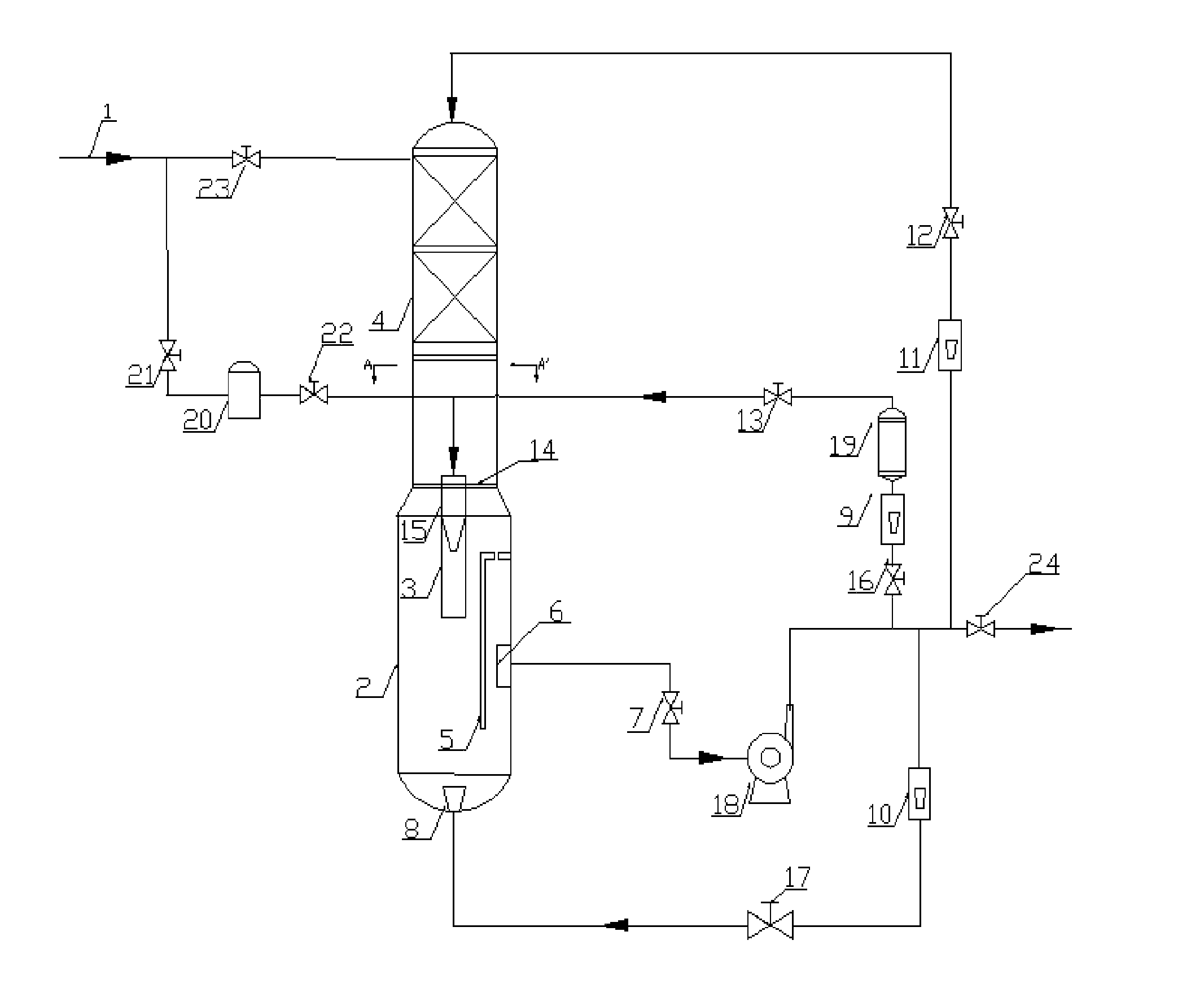

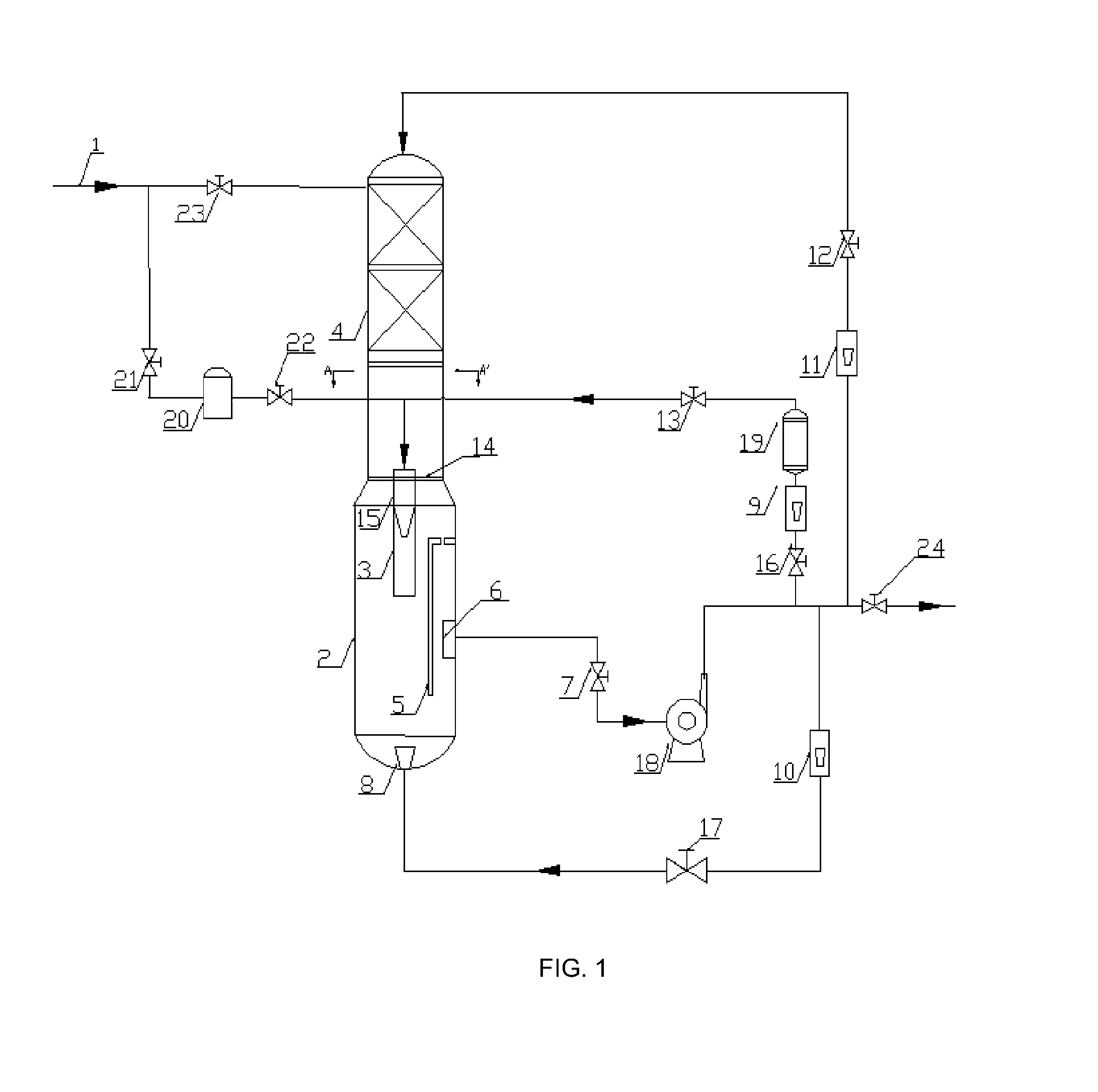

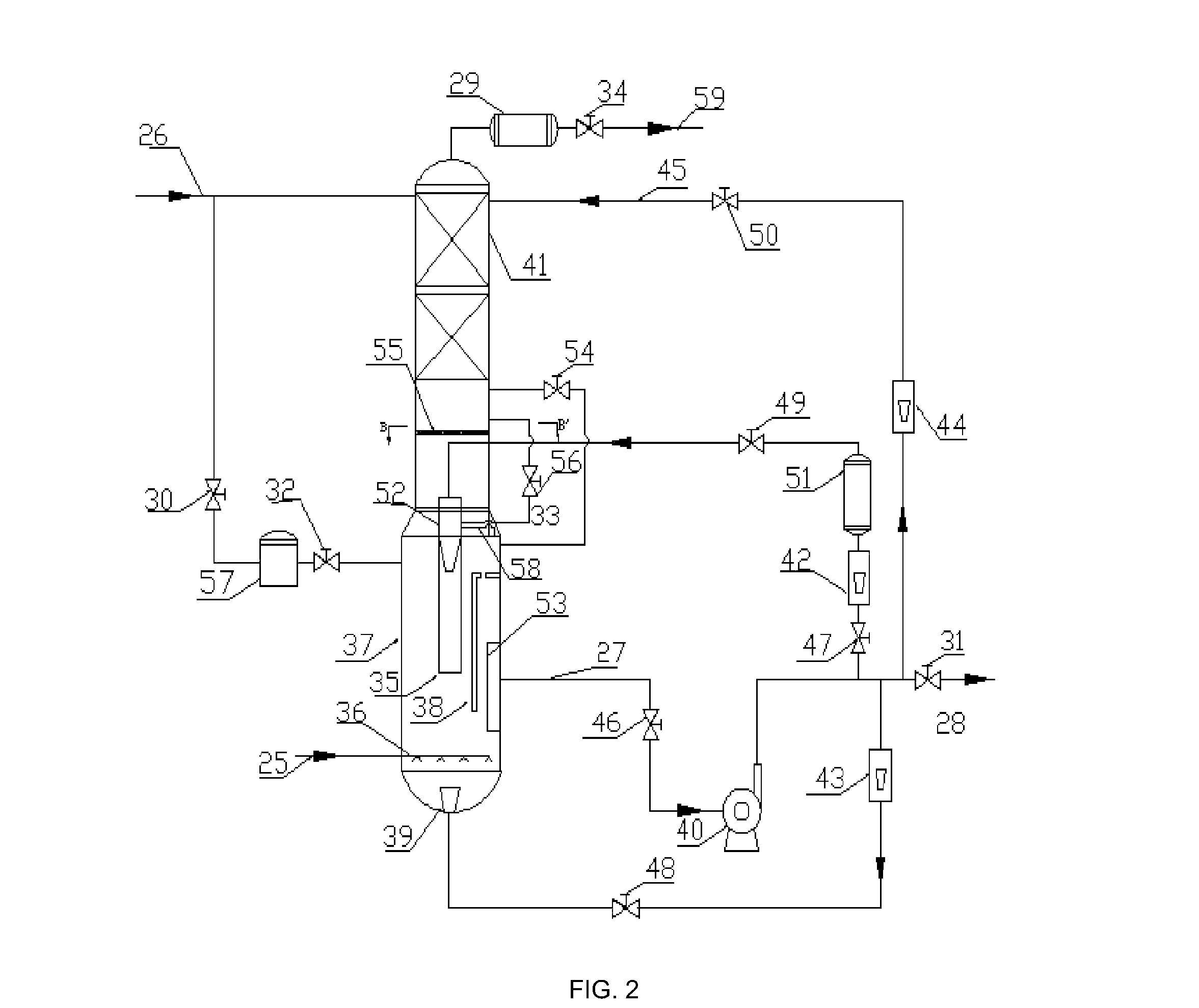

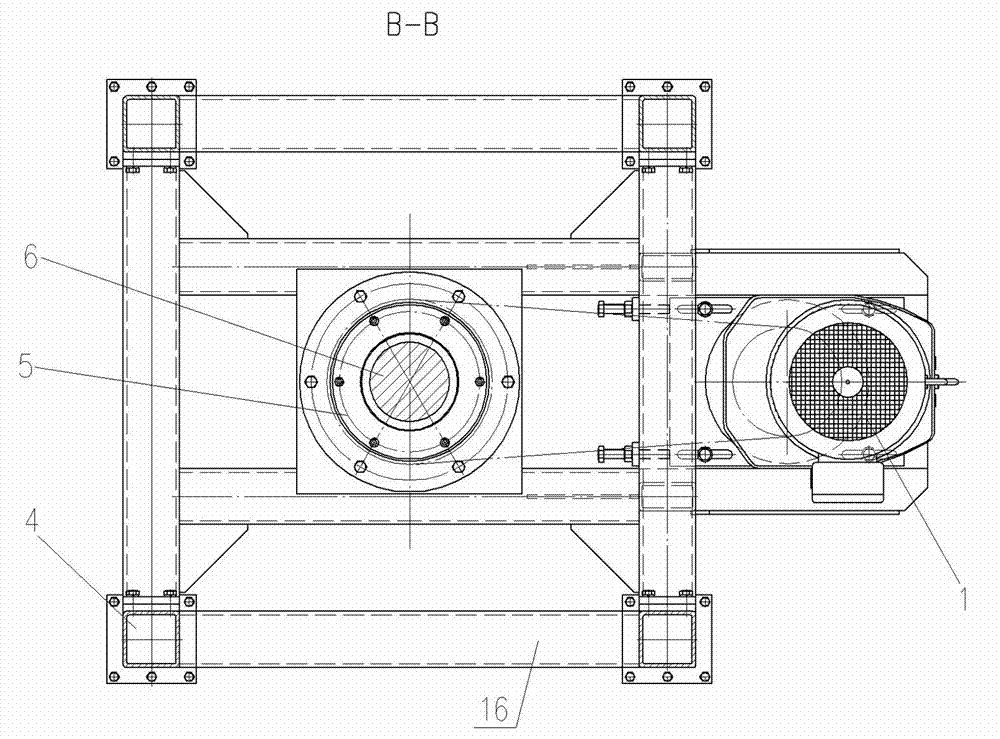

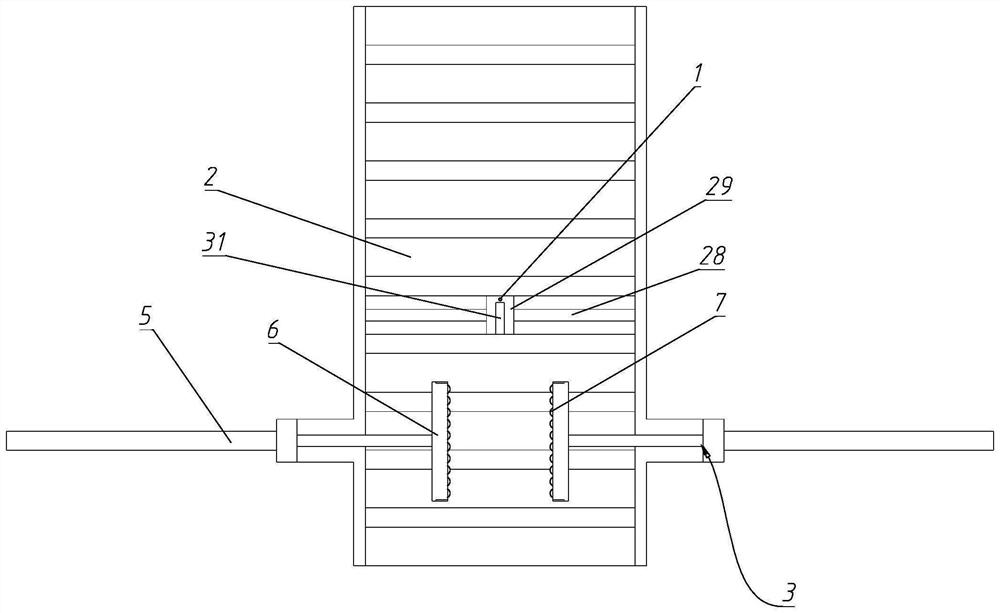

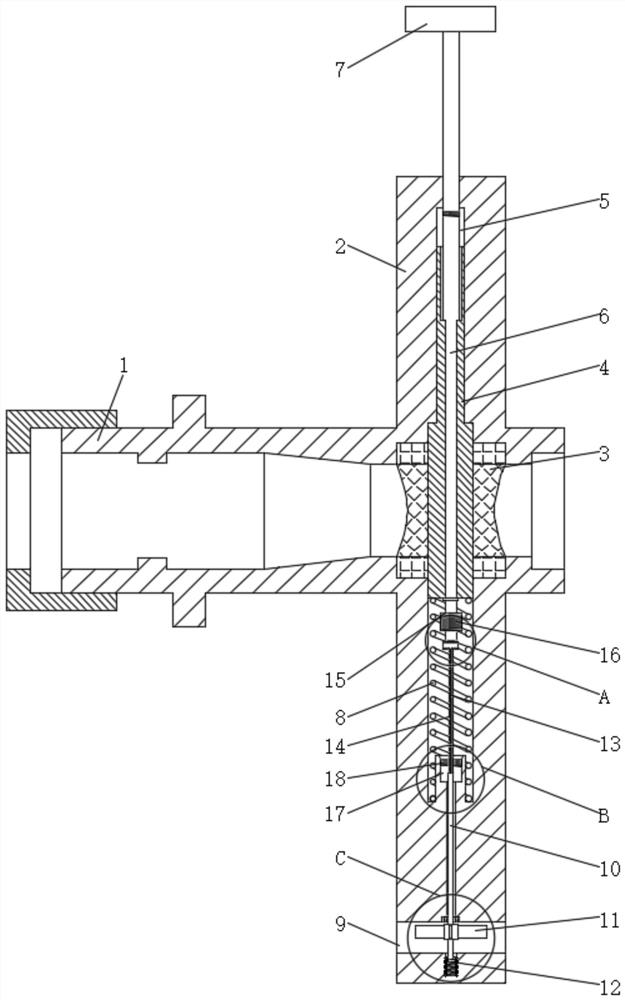

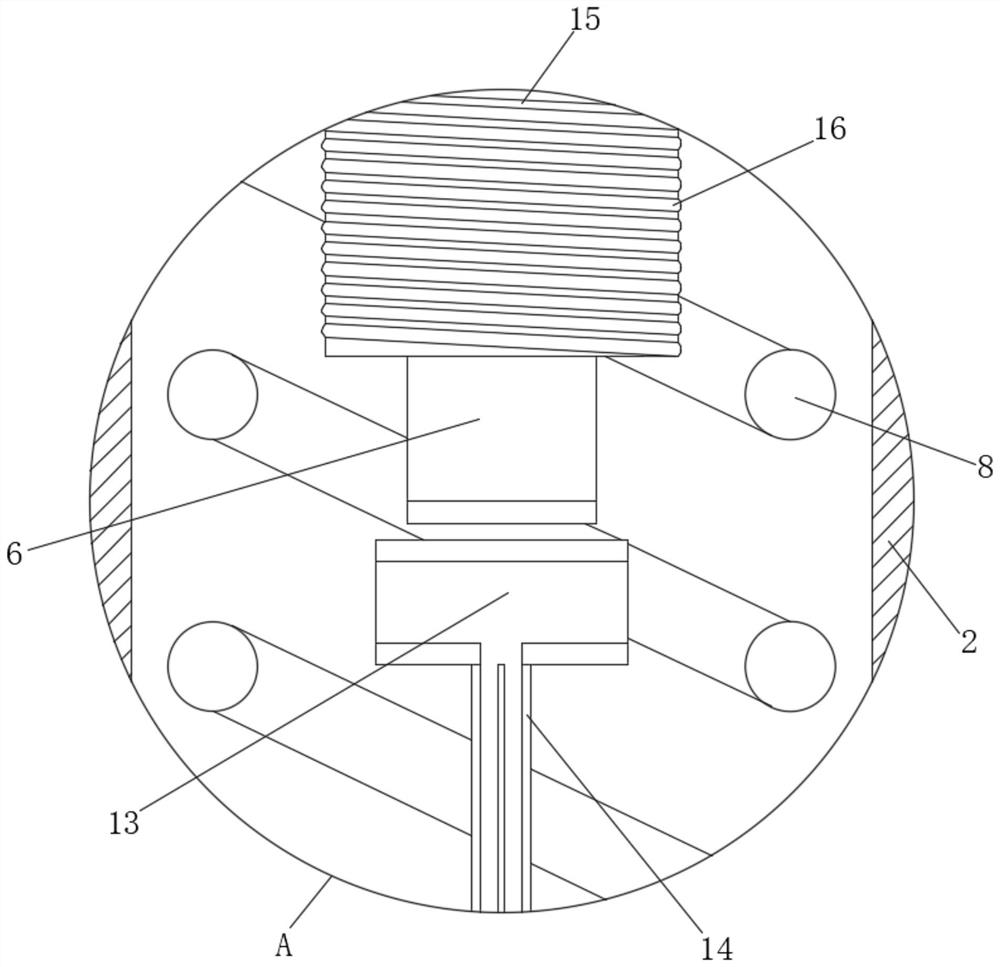

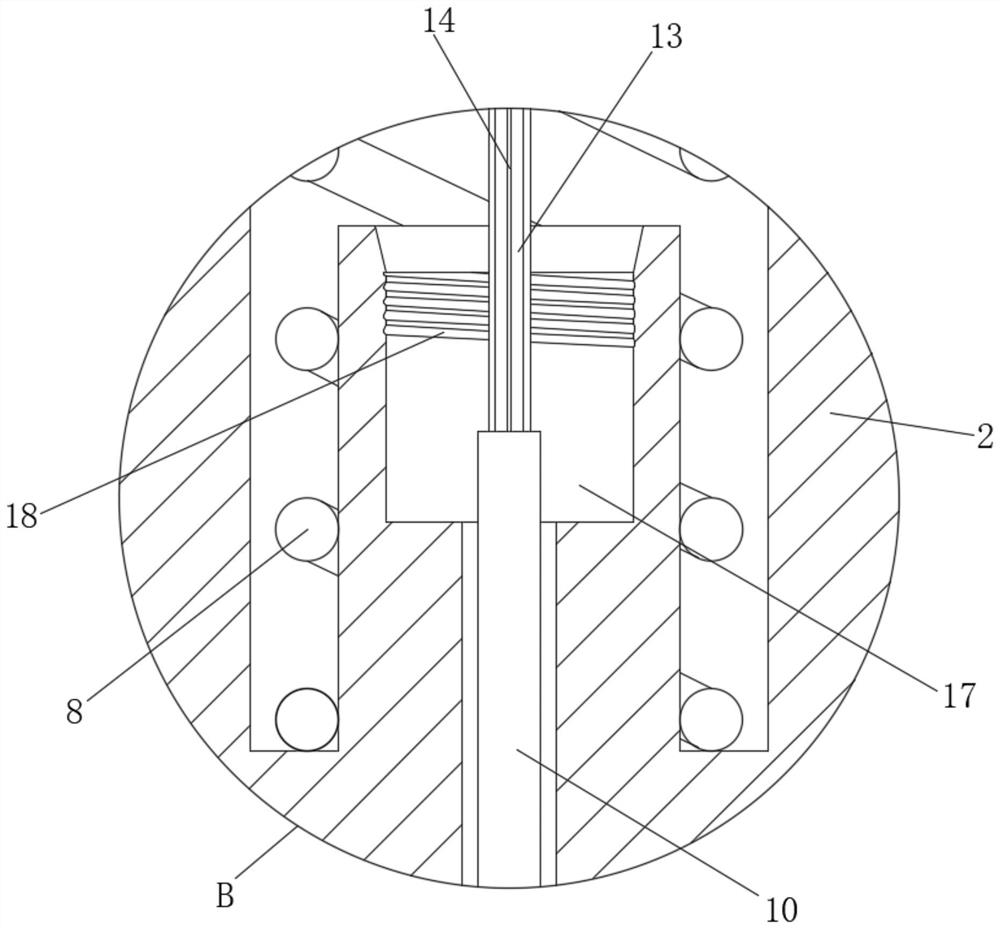

Multiphase catalytic tower-type impinging-stream reactor

ActiveUS20130129576A1Smooth connectionEqually distributedCatalytic liquid-gas reactionChemical/physical/physico-chemical stationary reactorsTowerInjector

A multiphase catalytic tower-shaped impinging-stream reactor in the form of a tower, the upper part of which is a plate or packed tower 4 and the lower part of which is a multiphase catalytic impinging-stream reaction kettle 2; the upper part and the lower part are separated by a flow channel plate 14 which has a plurality of round holes serving as flow channels 62; at the top of the reaction kettle 2 exists an upper ejector 3 and at the bottom of the reaction kettle 2 exists a lower ejector 8; near to the side wall of the reaction kettle 2 stands a baffle plate 5, which separates a static liquid zone within the reaction kettle 2 is disclosed.

Owner:NANJING UNIV

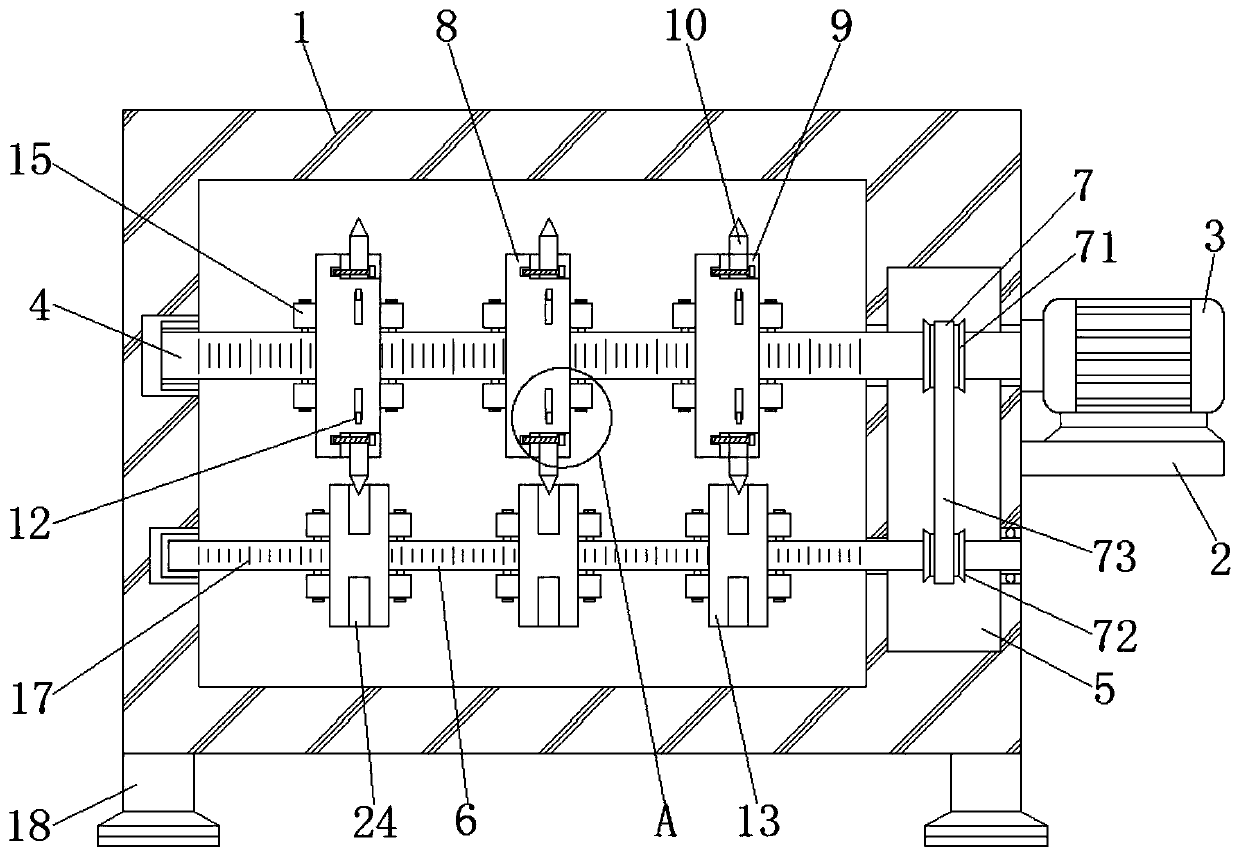

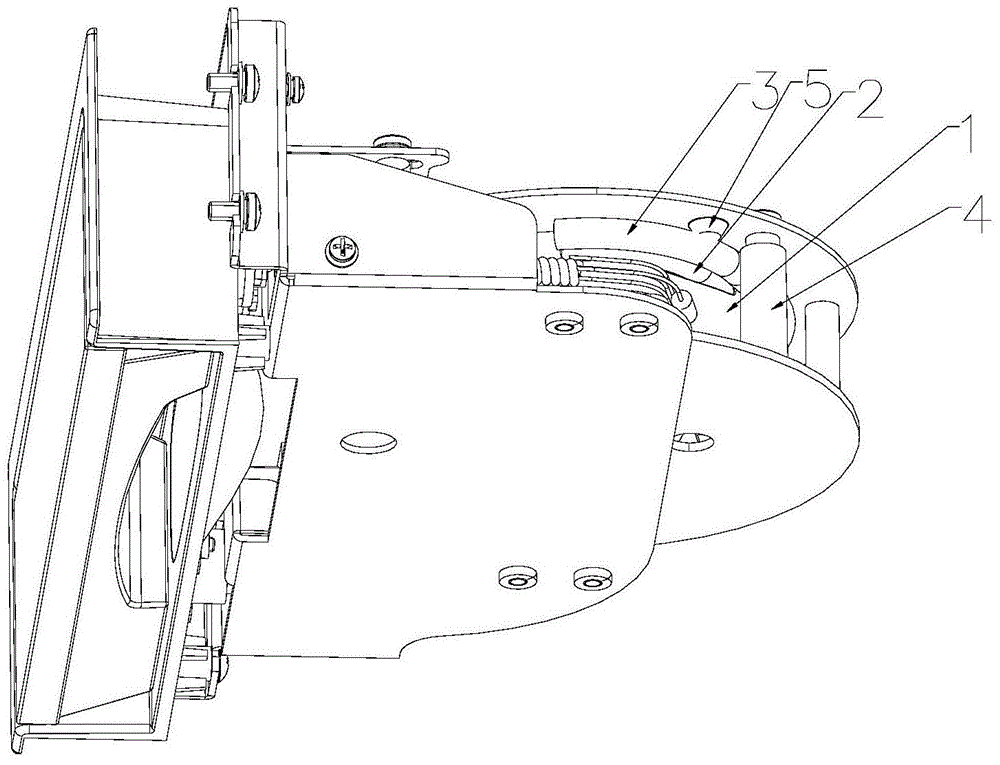

Grooving machine for carton production

InactiveCN109866465AEasy to operateStrong applicabilityPaper-makingBox making operationsElectric machineryDrive motor

The invention discloses a grooving machine for carton production, and belongs to the field of the carton production. The grooving machine for the carton production includes a machine frame, a supporting plate is fixedly connected to the right side of the machine frame, a driving motor is fixedly connected to the top of the supporting plate, and an upper pressure line roller is fixedly connected tothe left side of an output shaft of the driving motor; and a cavity is formed in the left side of the front side of the machine frame, and the left end of the upper pressure line roller penetrates through the machine frame and the cavity in sequence and extends into the machine frame. According to the grooving machine for the carton production, a worn grooving cutter can be removed from an upperpressure line wheel by the cooperation of an installation groove, a limiting opening and a limiting fixing device and a new grooving cutter can be replaced; the operation is easy, and the convenienceand the quickness are realized; by the cooperation of a slot, an installation block and a telescopic limiting device, the positions of the upper pressure line wheel and a lower pressure line wheel canbe adjusted, adjusting the position of the grooving cutter according to cartons with different sizes for users is convenient, and the applicability of the grooving machine is enabled to be better.

Owner:珠海市祥英纸品包装有限公司

Carpets with improved fuzz-resistance

Tufted carpets bonded with thermoplastic binders and having improved resistance to fuzz formation due to removal of pile yarn filaments from tuft bundles comprise one or more backings, face yarn that forms a pile on one side and stitches on an opposite side, a thermoplastic binder that binds stitches and the backing or backings, and an organic polymer that bonds filaments of the stitches. Processes for making carpets comprise applying to a stitched side of a tufted backing a liquid stitch bind composition comprising an organic polymer component, removing a liquid component of the composition to bond filaments of the stitches and bonding stitches and one or more backings with a thermoplastic binder that is melted or applied as a melt in contact with the stitched side and the backing or backings and solidified.

Owner:PROPEX OPERATING

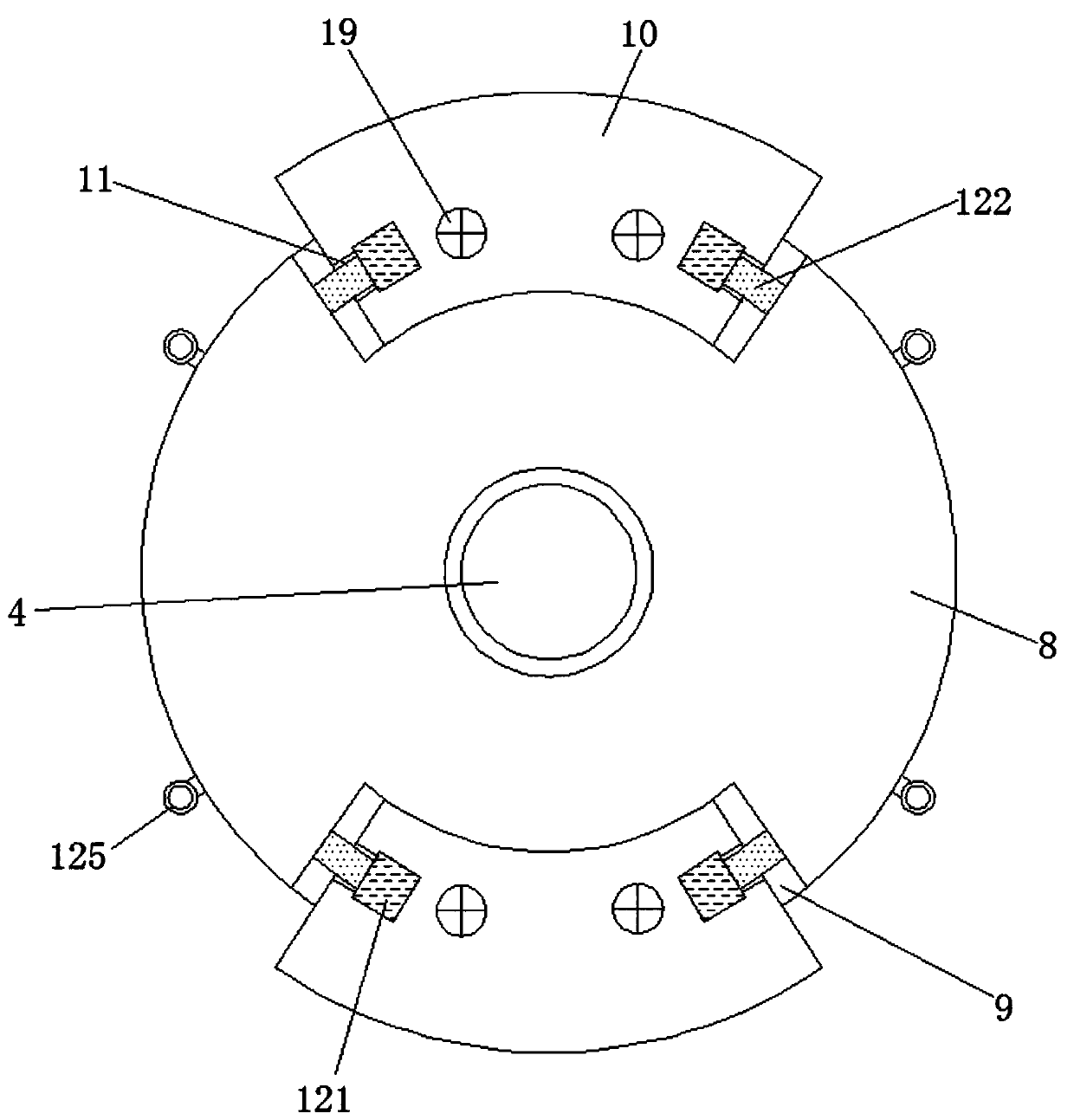

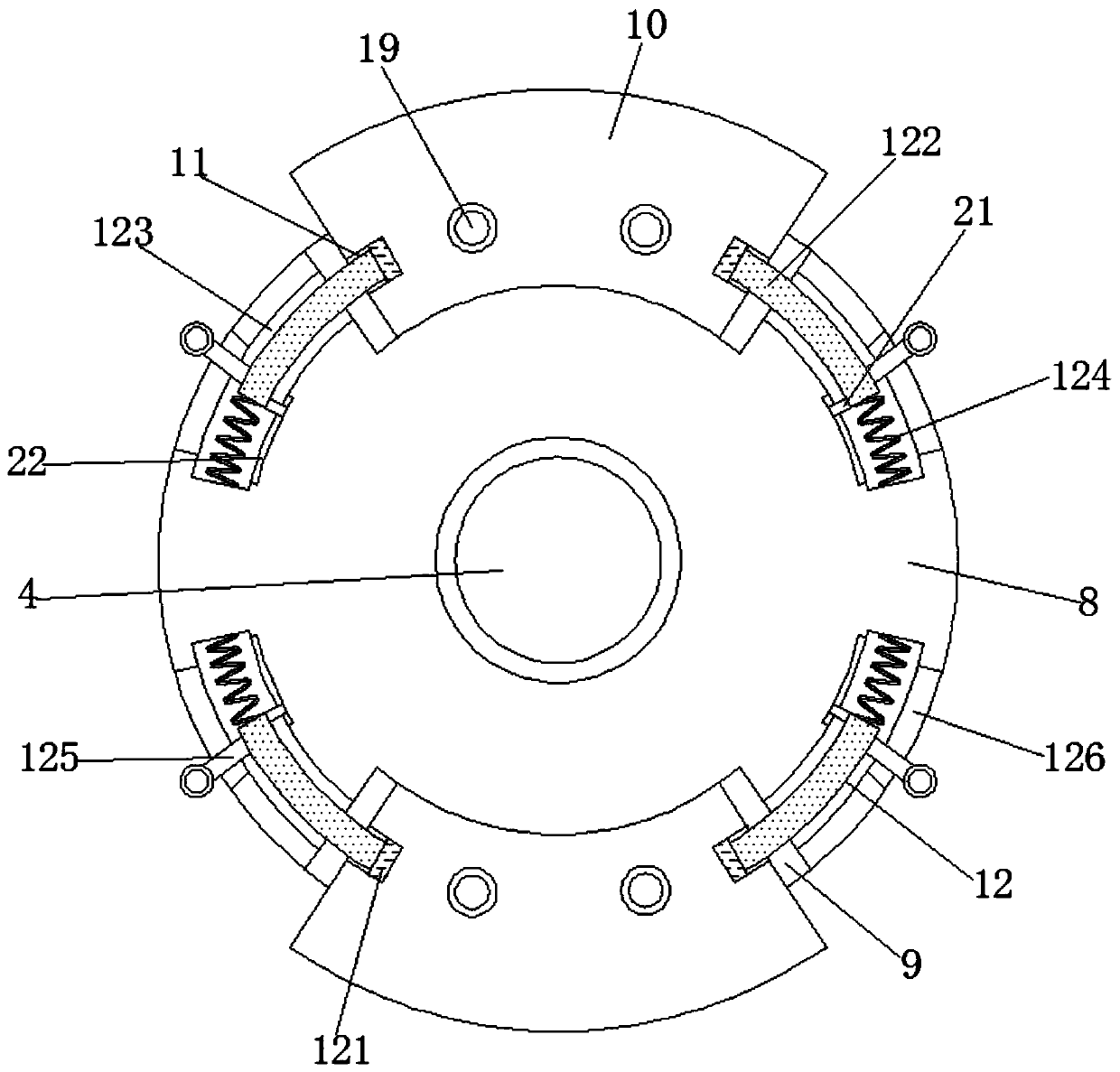

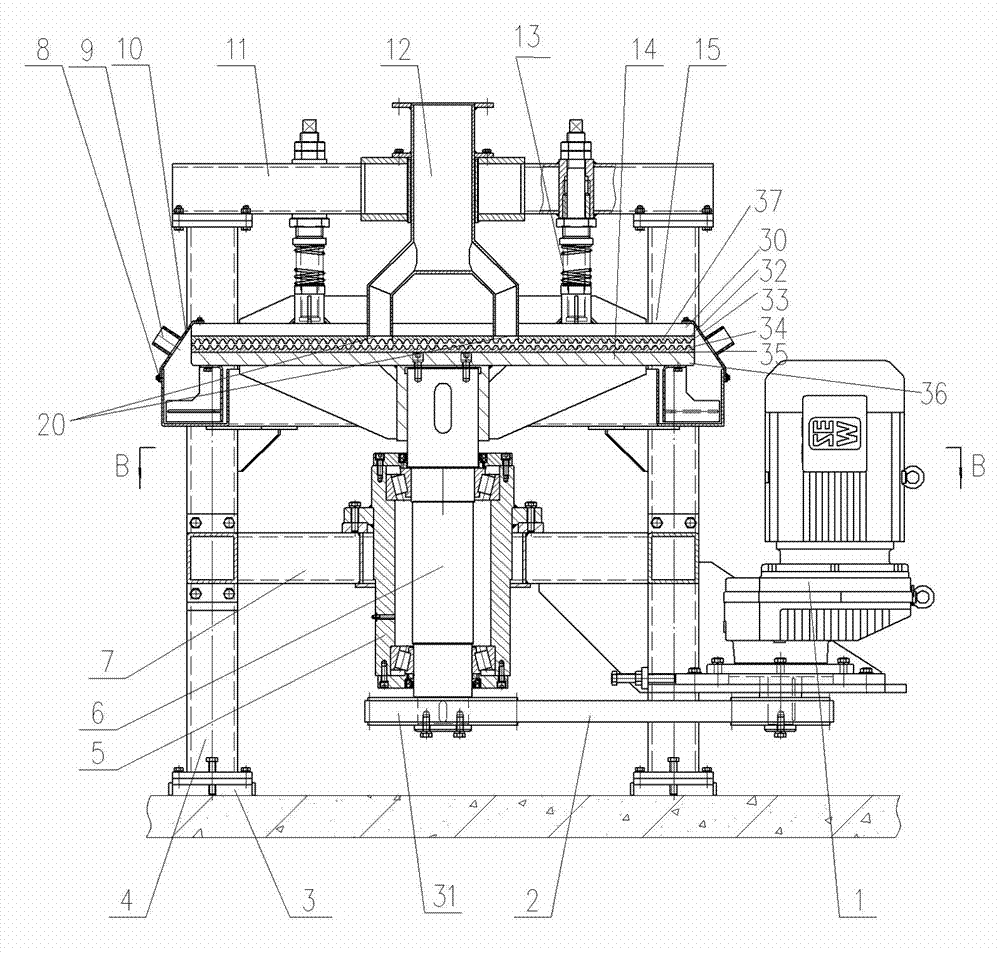

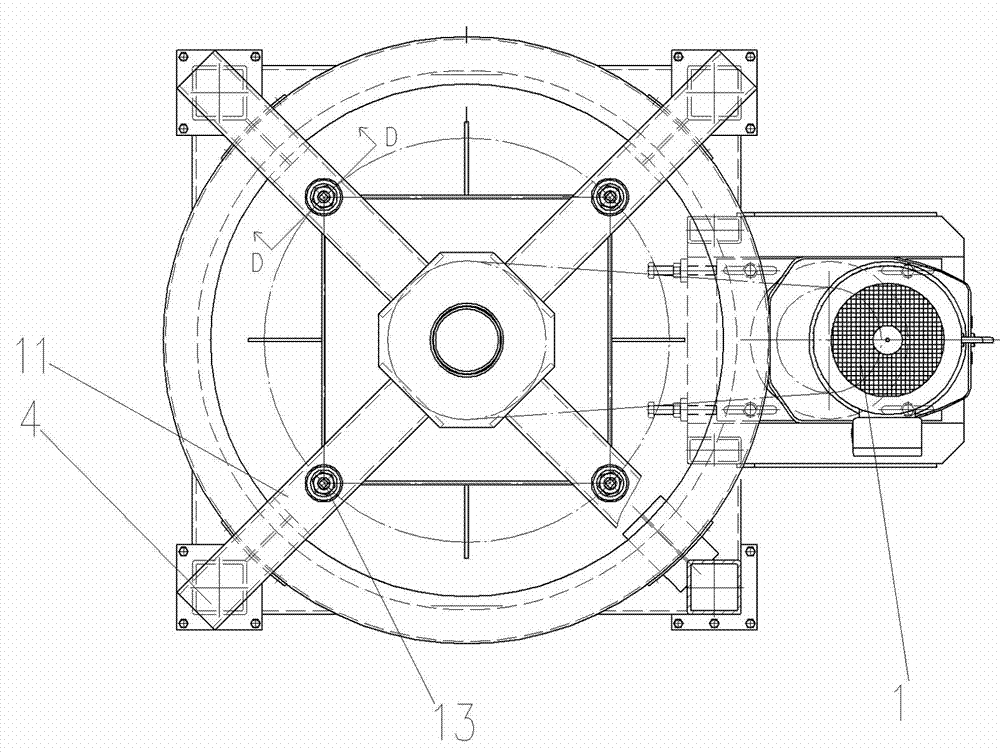

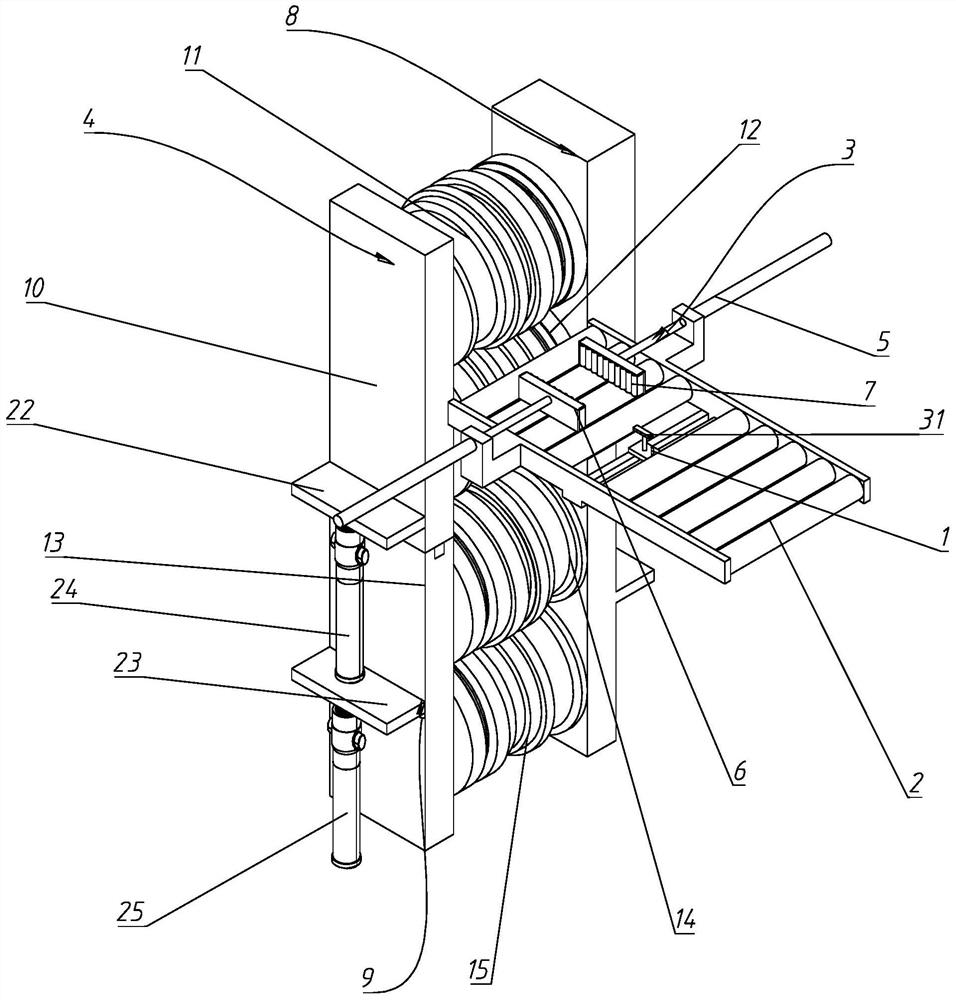

Used sand regeneration mechanism

The invention relates to an used sand regeneration mechanism, which comprises an upper millstone and a lower millstone with up and down relative arrangement, one of the upper millstone and lower millstone can bear loading force and rotate relative to another millstone, an upper millstone surface is provided at the lower end of the upper millstone, a lower millstone surface positioned relative to the upper millstone surface and used for cooperating with the upper millstone surface for extruding and twisting the corresponding used sand particles, and an accommodation gap used for accommodating the corresponding used sand particles is provided between the upper millstone surface and the lower millstone surface. The invention provides the used sand regeneration mechanism with low use cost, and the used sand particles are difficult to be crushed during the regeneration of the used sand.

Owner:SCIVIC ENGINNEERING

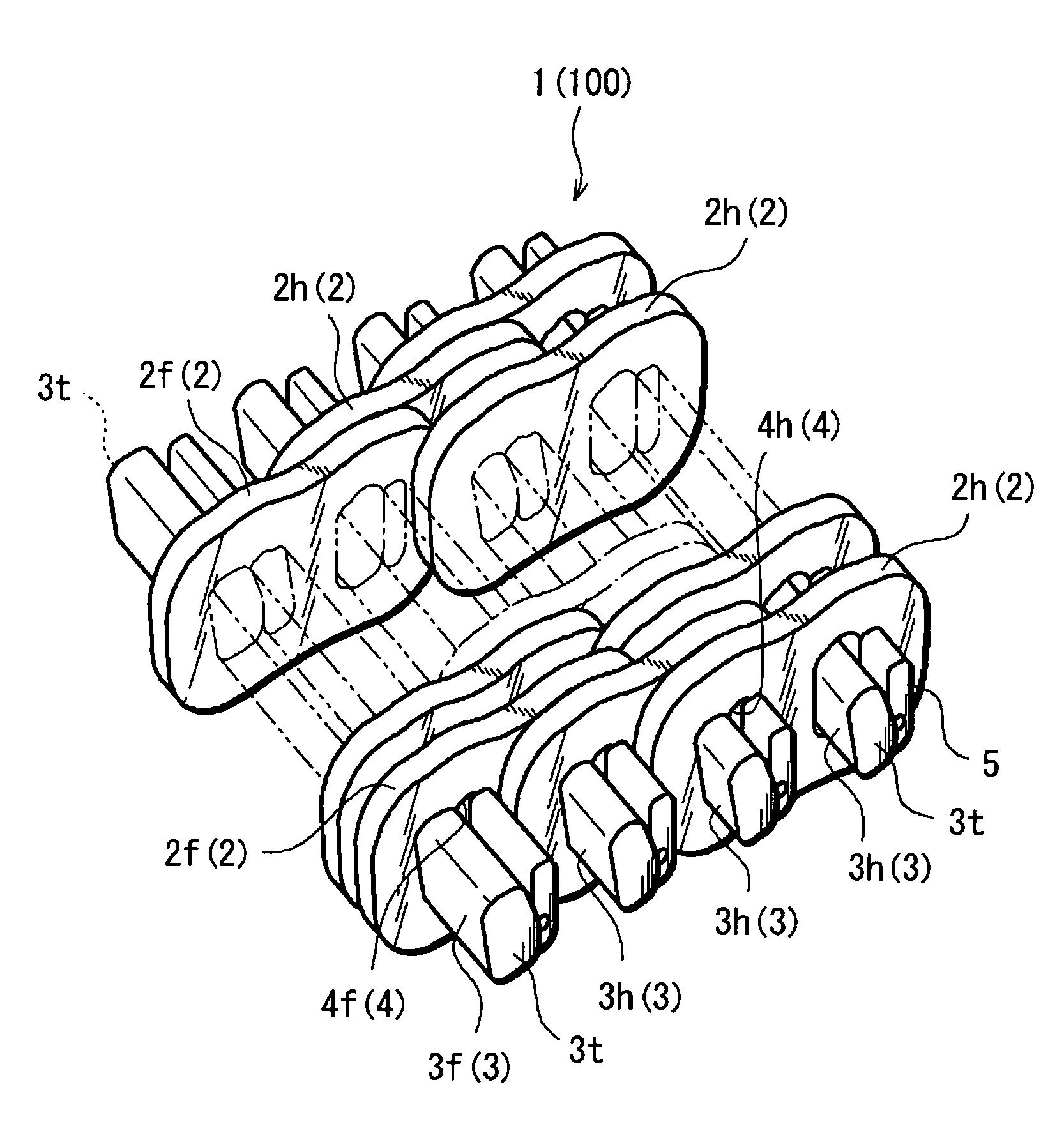

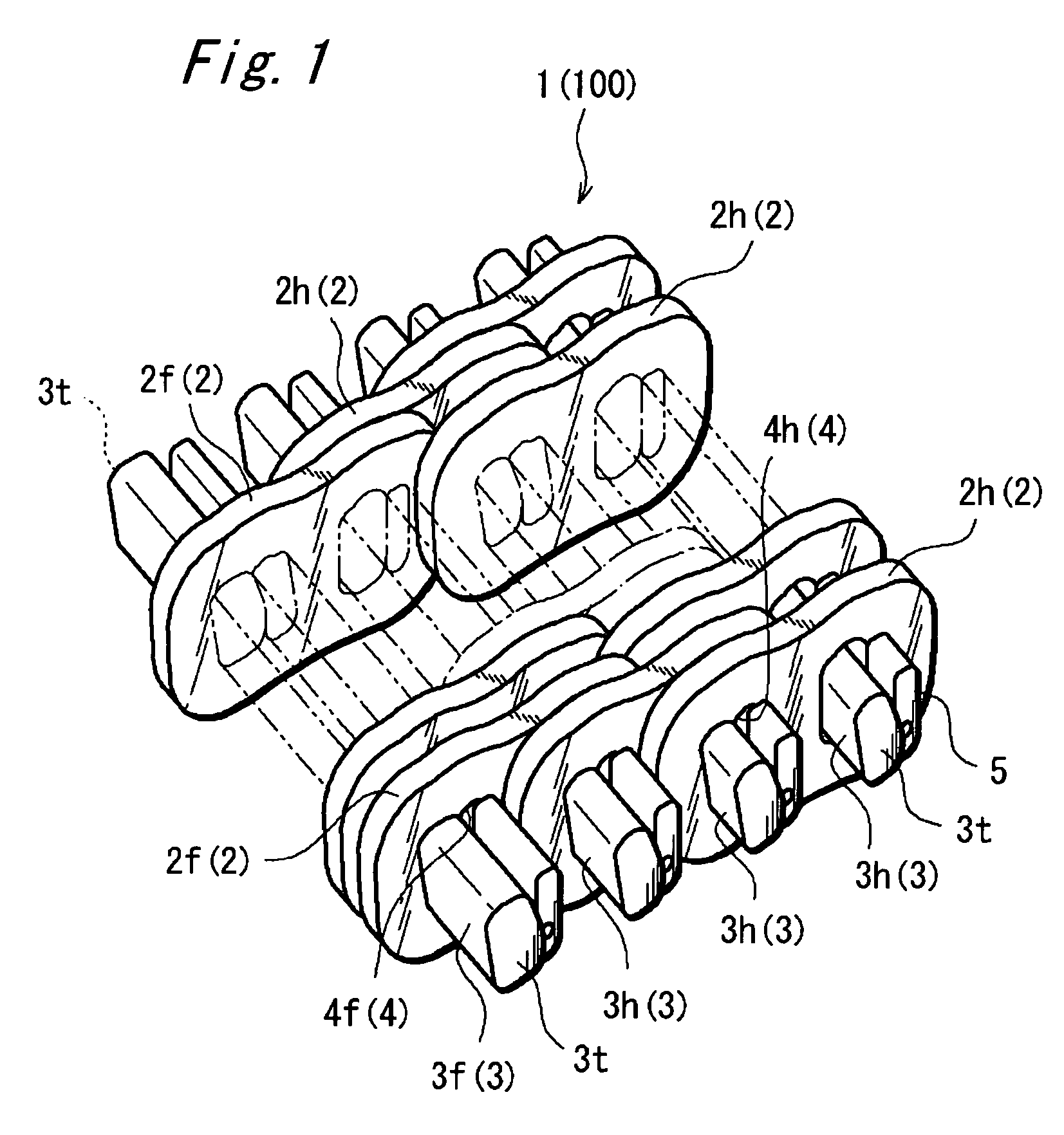

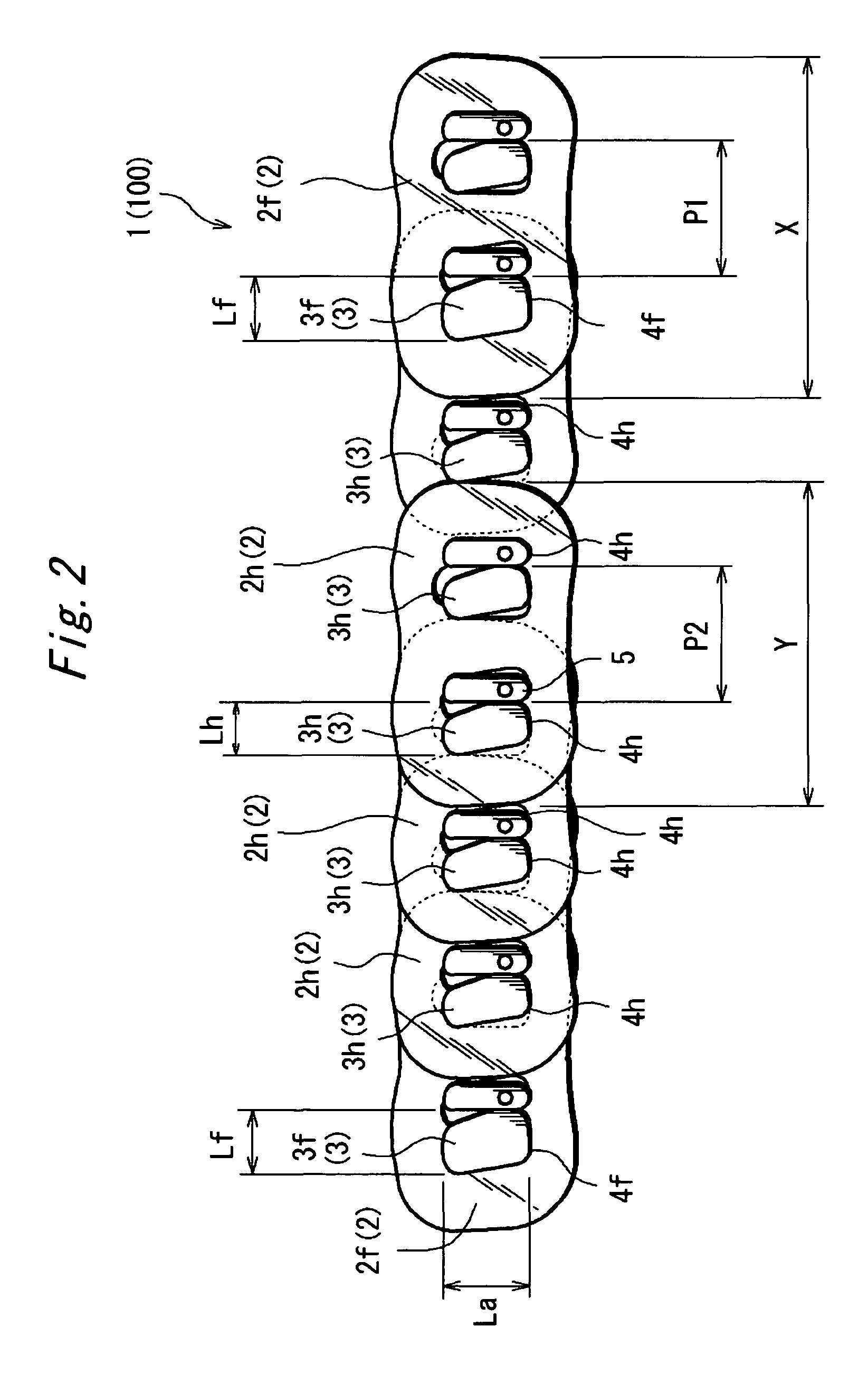

Power transmission chain and power transmission assembly using the same

InactiveUS7993229B2Badly wornReduced durabilityV-beltsRopes and cables for vehicles/pulleyInvoluteContact position

An object of the invention is to provide a power transmission chain capable of effectively reducing noises and a power transmission assembly using the same. In the power transmission chain including plural links each possessing through-holes and plural pins inserted through the through-holes for interconnecting the plural links, all the plural pins substantially have the same longitudinal length while the plural pins include plural types of pins which have mutually different rigidities against force acting in the pin longitudinal direction. Furthermore, a locus of contact position between the pin and a strip is defined by an involute of a circle. The pins and strips are combined to form two or more types of pairs which provide the involutes of base circles having different radii.

Owner:JTEKT CORP

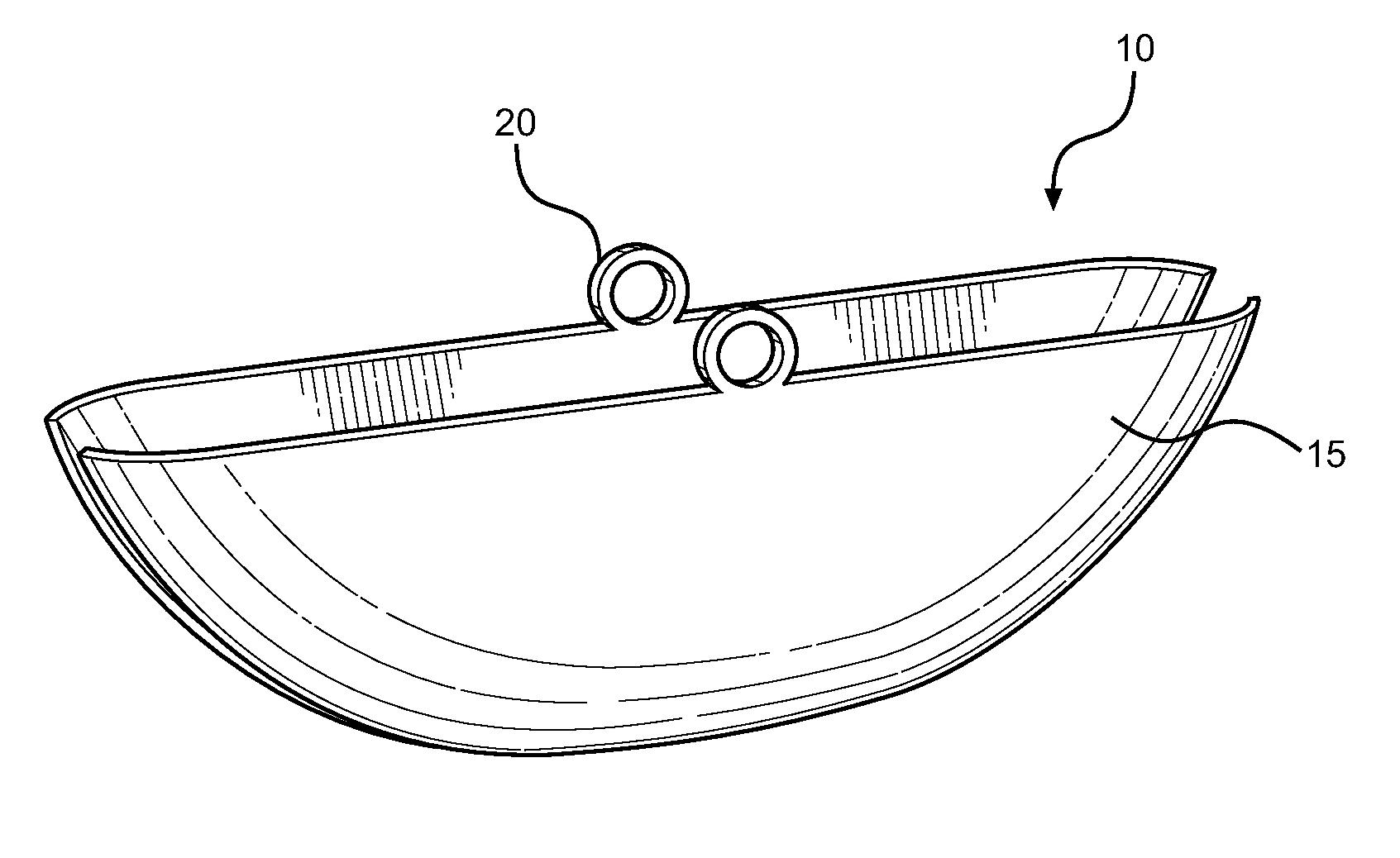

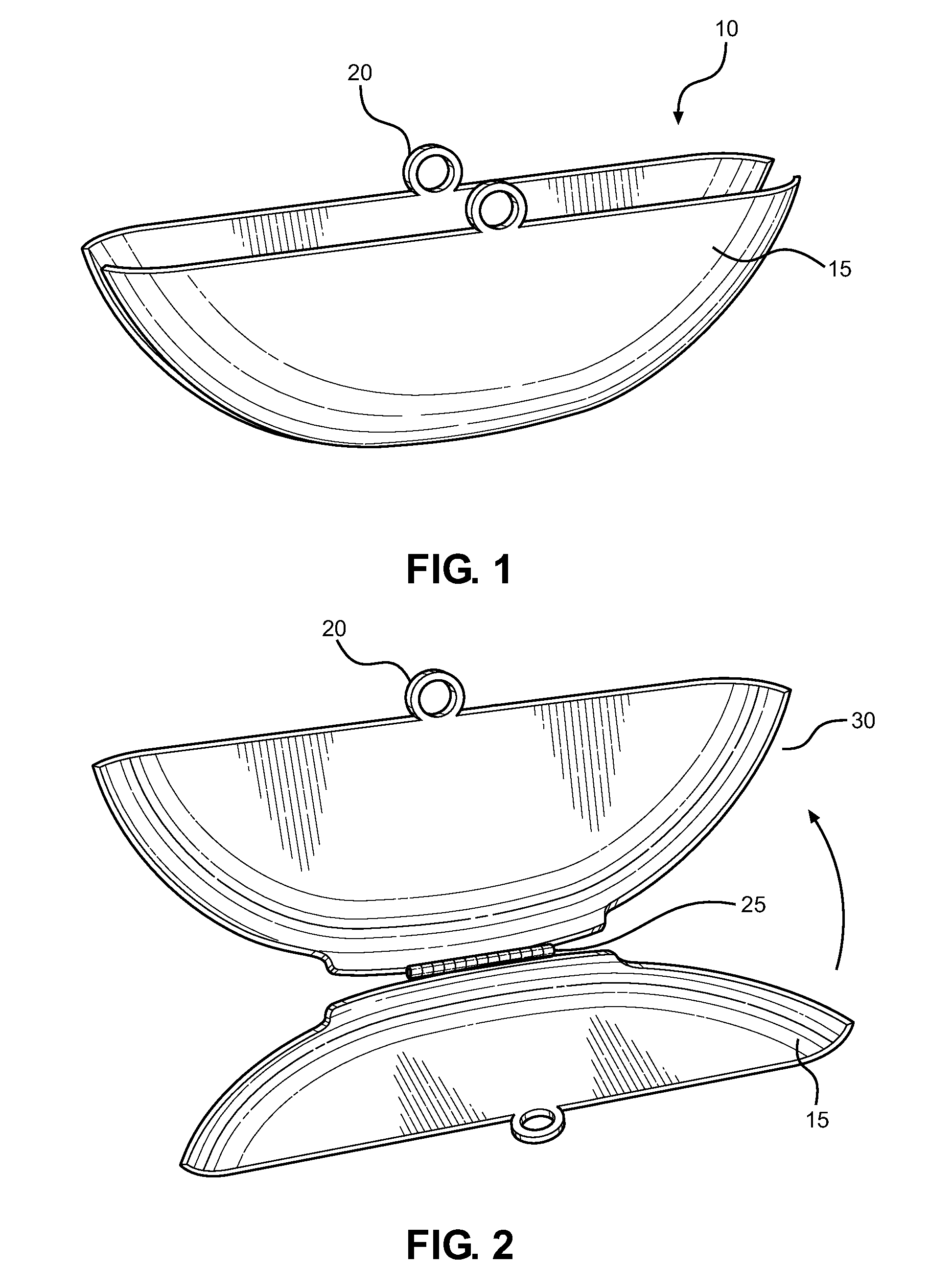

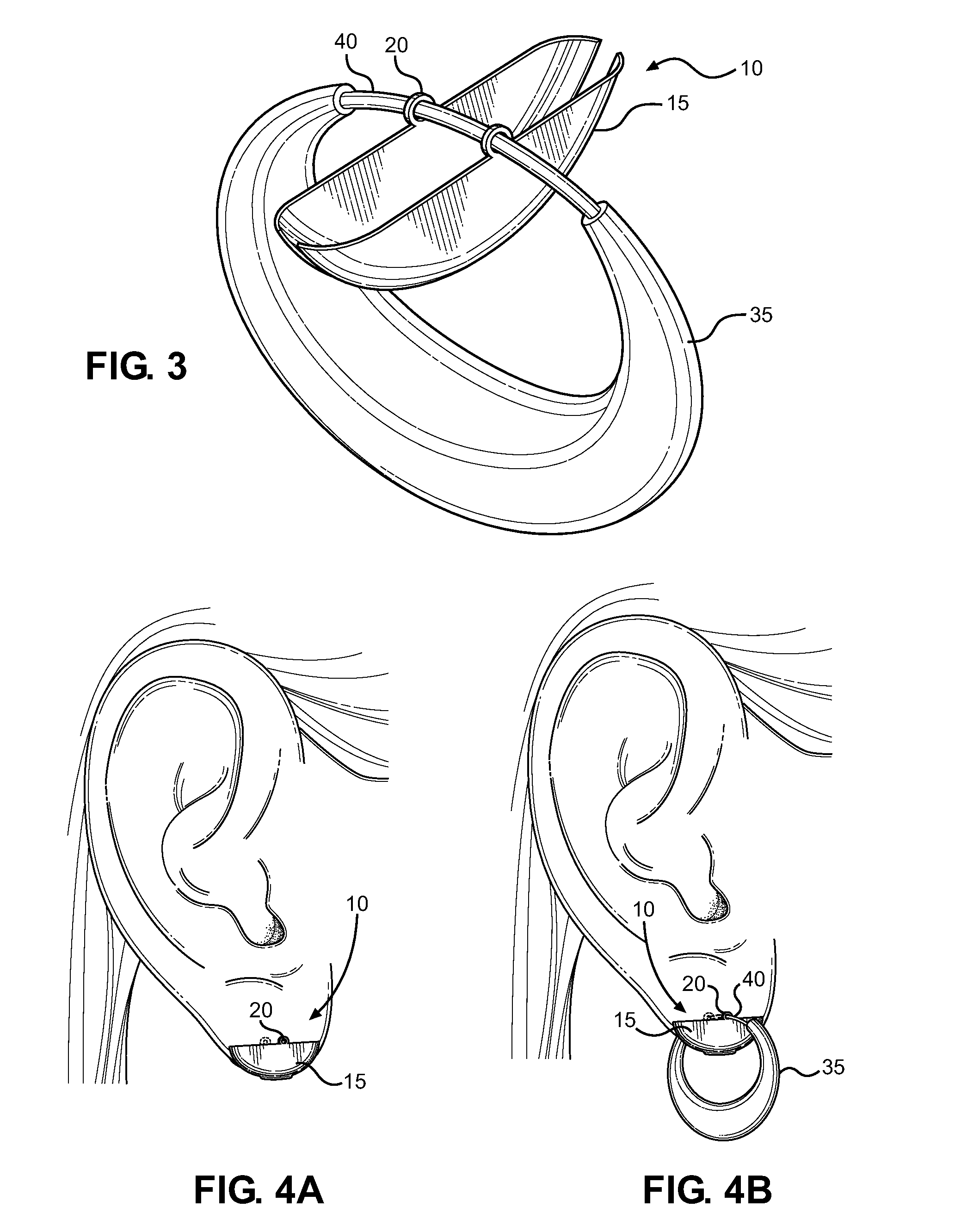

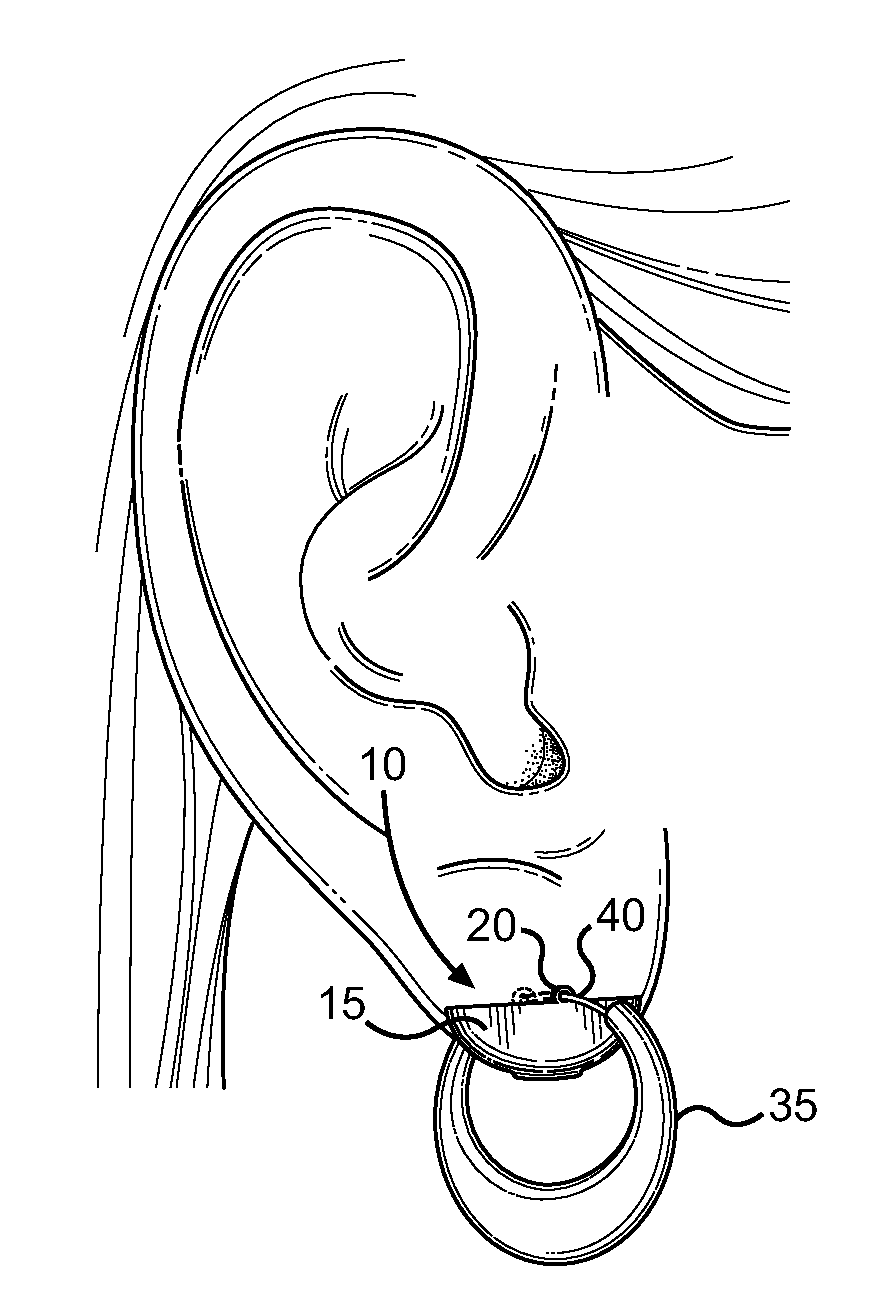

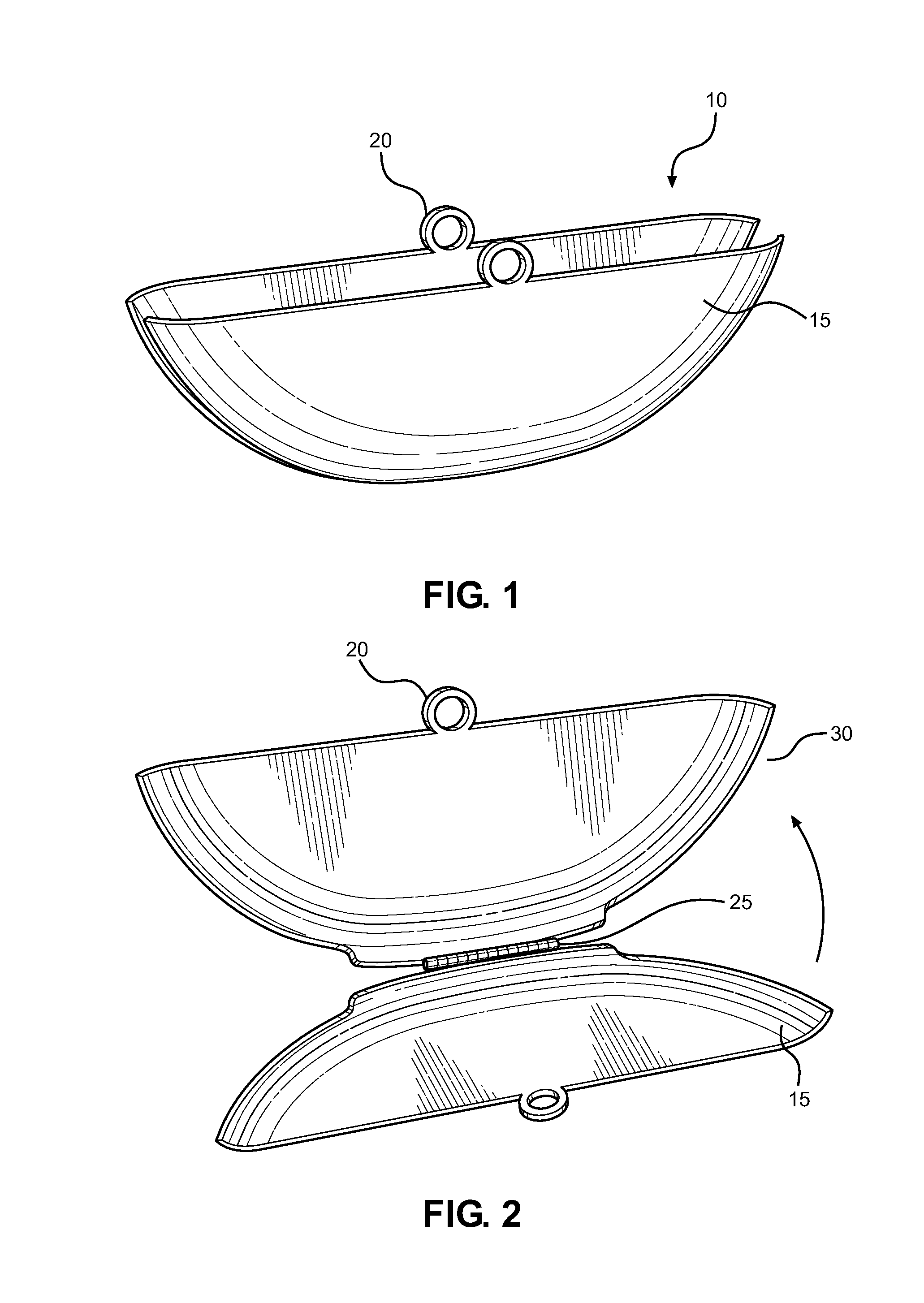

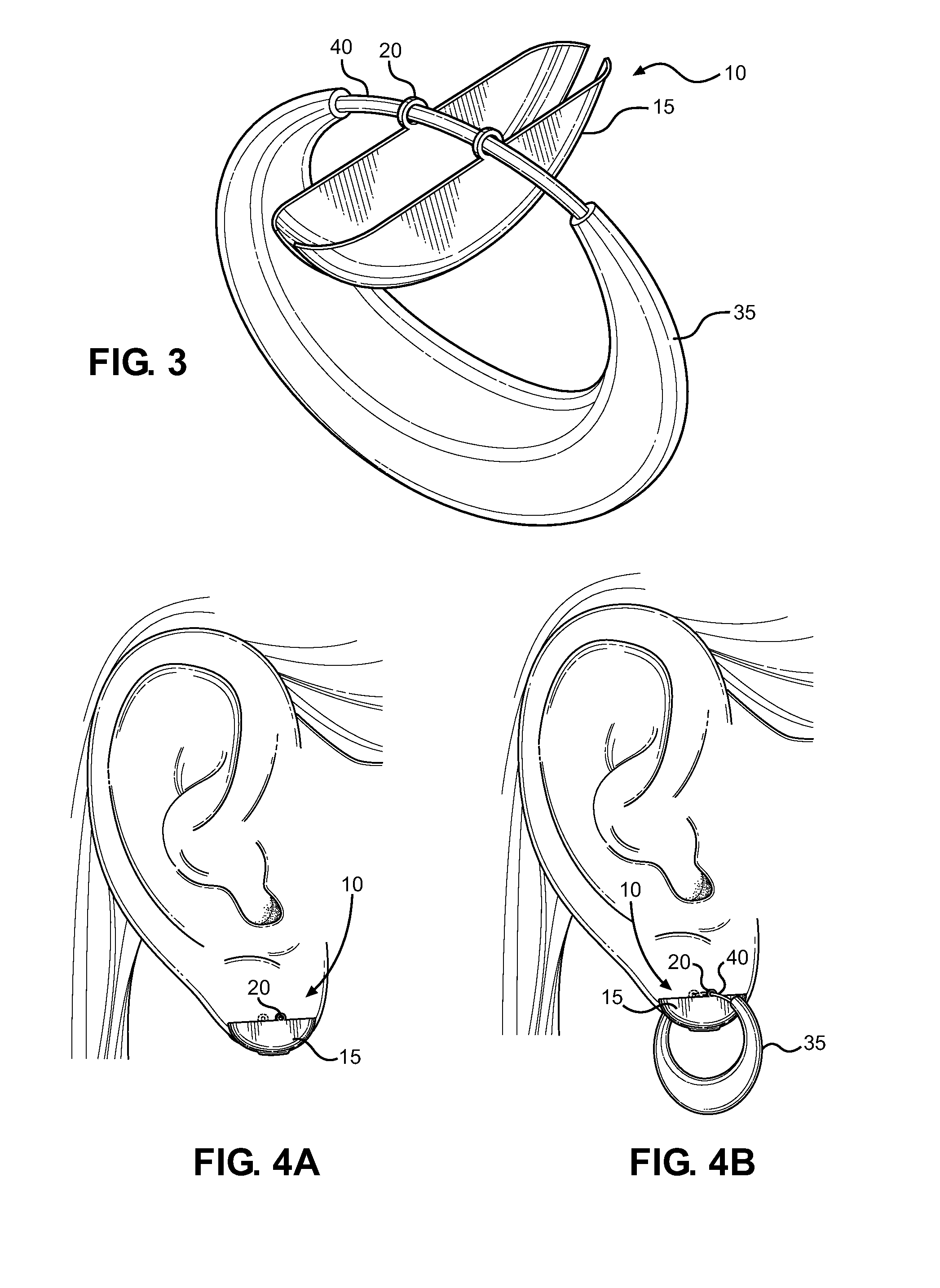

Earring support device

The present invention describes an earring support device for relieving the tension caused by having large earrings hanging from a piercing for an extended amount of time. The support device has a set of clam-shell shaped earlobe guards that are hinged together and clipped onto an earlobe. The earring support device further has apertures that correspond with that of the ear piercing, wherein when the pin of the earring is placed through the earring support device apertures, the earring support device functions to distribute the forces applied by the earring more evenly through the earlobe. The clam-shelled halves of the earring support device cover an area from the piercing to the bottom of the earlobe, and thus further serves to mask the effects of prior extended wearing of heavy jewelry.

Owner:WILMER ANGELA MARIA

Method for cutting extruded profile sections into lengths

A method for cutting a hollow extruded profile section into lengths in a press flow, wherein the extruded profile section is bent upon exit from the press either simultaneously with or directly after the forming extrusion process by a force acting thereon in a transversal manner in relation to the direction of the extruding press, and a force component acts as a traction of pressure force during the forming extrusion process on the cross-sectional area of the hollow-profile walls thus arising. The bent extruded profile section is cut in the press flow by the mechanical action of a saw, whereby force exerted on the extruded profile section during cutting is compensated by a supporting device arranged adjacent to the extruded profile section, so that deformation of the bent extruded profile section is prevented.

Owner:WKW ERBSLOEH AUTOMOTIVE GMBH

High-cleaning, low abrasion, high brightness silica materials for dentrifices

InactiveUS20070224132A1Excellent abrasionImprove rendering capabilitiesPigmenting treatmentCosmetic preparationsEngineeringSilica gel

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Earring Support Device

InactiveUS20140102137A1Distributes forceConceals effect of extended wearing of heavy jewelryEar-ringsBiomedical engineeringEar piercing

The present invention describes an earring support device for relieving the tension caused by having large earrings hanging from a piercing for an extended amount of time. The support device has a set of clam-shell shaped earlobe guards that are hinged together and clipped onto an earlobe. The earring support device further has apertures that correspond with that of the ear piercing, wherein when the pin of the earring is placed through the earring support device apertures, the earring support device functions to distribute the forces applied by the earring more evenly through the earlobe. The clam-shelled halves of the earring support device cover an area from the piercing to the bottom of the earlobe, and thus further serves to mask the effects of prior extended wearing of heavy jewelry.

Owner:WILMER ANGELA MARIA

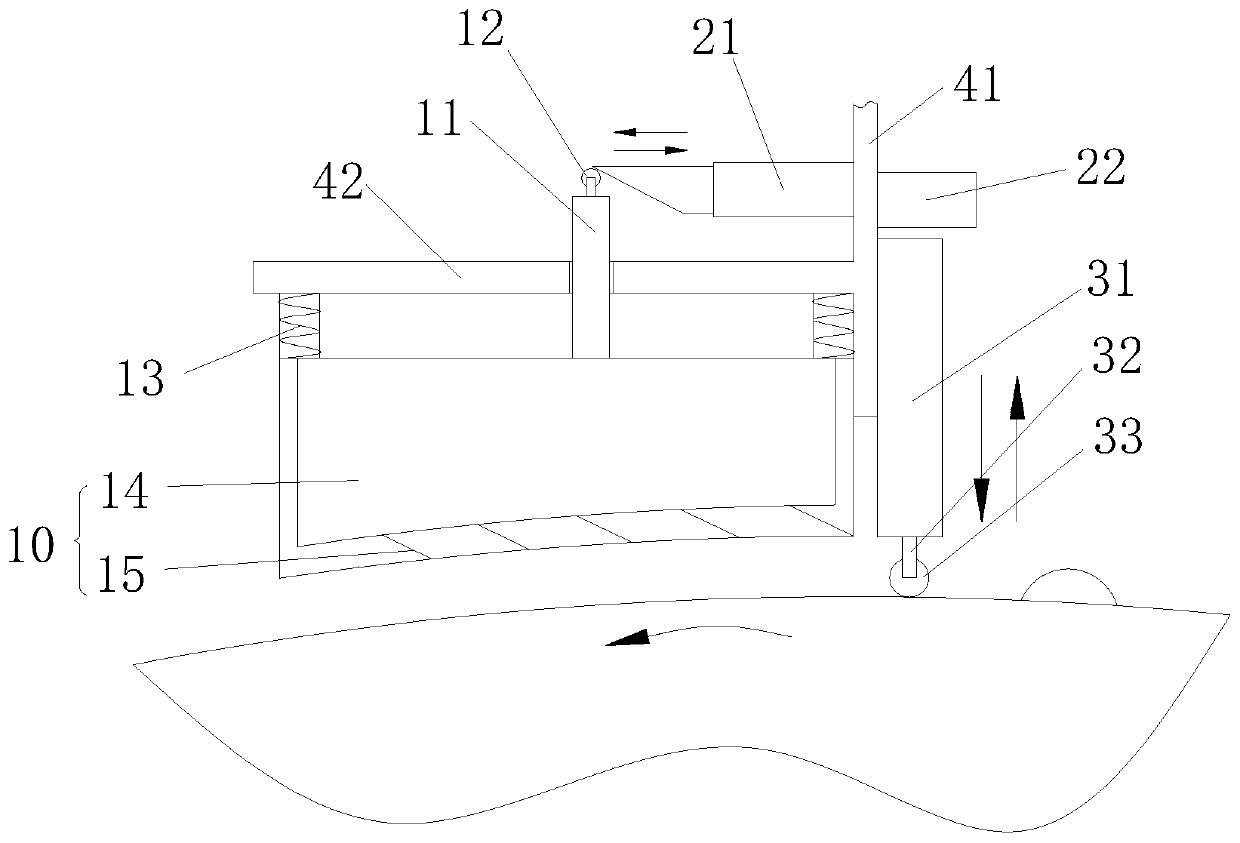

Cleaning device for surface of paperboard dryer

The invention provides a cleaning device for a surface of a paperboard dryer. The cleaning device comprises a cleaning mechanism, a driving mechanism, a detecting mechanism and a fixing frame. The cleaning mechanism is used for cleaning pollutants on the dryer surface, the driving mechanism is used for driving the cleaning mechanism so as to enable the cleaning mechanism to clean the dryer surface, the detecting mechanism is used for detecting whether the pollutants exist on the dryer surface or not, and when the pollutants exist on the dryer surface, the driving mechanism is started; the fixing frame is used for fixing the cleaning mechanism, the driving mechanism and the detecting mechanism; the fixing frame comprises a first fixing plate and a second fixing plate, the first fixing plateis perpendicular to the dryer surface, the second fixing plate is perpendicular to the first fixing plate, and is fixedly arranged on one side of the first fixing plate, the cleaning mechanism is arranged on the side, provided with the second fixing plate, of the first fixing plate, and the cleaning mechanism slides up and down along the first fixing plate. The other side of the first fixing plate is provided with the detecting mechanism, and the detecting mechanism slides up and down along the first fixing plate.

Owner:宣城万里纸业有限公司

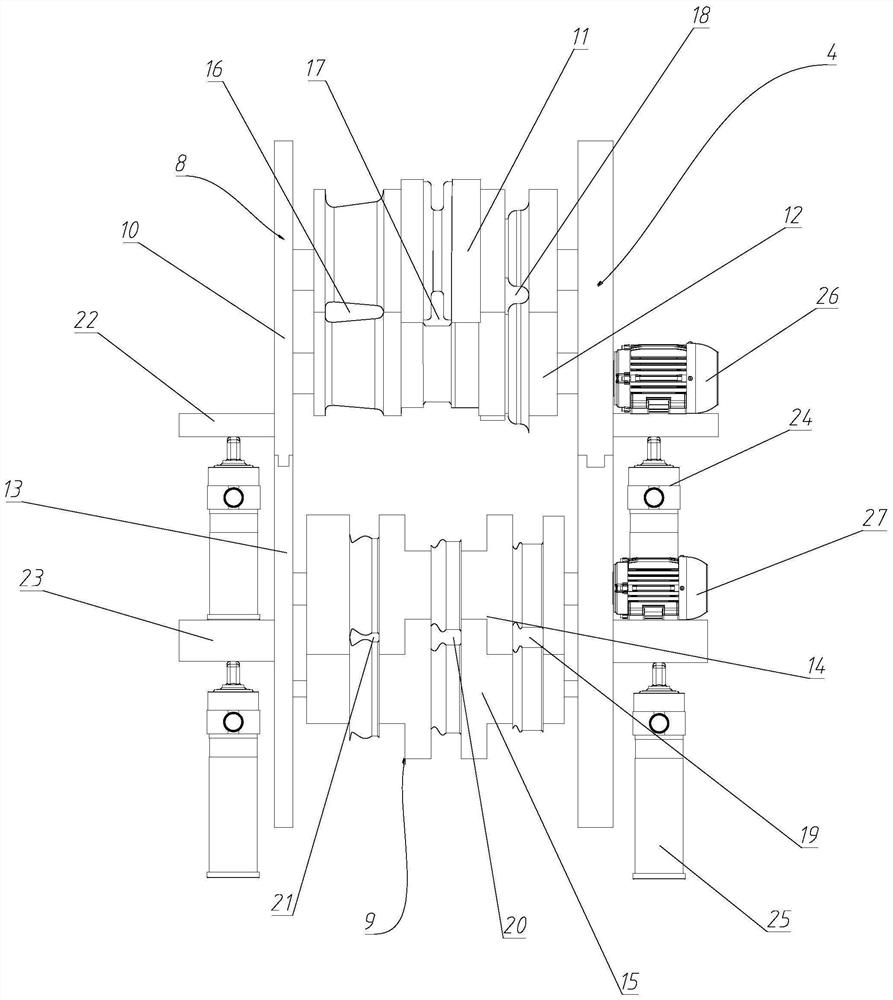

Light rail profile steel rolling equipment and process based on pre-bending cooling technology

PendingCN113798335ABadly wornReduce wearMetal rolling stand detailsGuiding/positioning/aligning arrangementsEngineeringLight rail

The invention relates to the technical field of rolling, and provides light rail profile steel rolling equipment and process based on the pre-bending cooling technology. The light rail profile steel rolling equipment comprises a guide device and a rough rolling device which are arranged on a rack in the conveying direction of a conveying device, wherein the guide device comprises third telescopic pieces, guide plates and guide rolling shafts, and the third telescopic pieces are arranged on the rack and positioned on the two sides of the conveying device; the guide plates are arranged at the telescopic ends of the third telescopic pieces, and the guide rolling shafts are rotationally arranged on the guide plates;the rough rolling mechanism comprises a first rough rolling device and a second rough rolling device; the first rough rolling device is arranged on the rack in a sliding mode and positioned on the rack in the conveying direction of the conveying device, and the second rough rolling device is arranged on the rack in a sliding mode and positioned at the bottom of the first rough rolling device; and the sliding direction of the first rough rolling device and the sliding direction of the second rough rolling device are perpendicular to the conveying direction of the conveying device. By means of the technical scheme, the problems that in the prior art, rough rolling is large in occupied area, and a guide structure is abraded are solved.

Owner:河北永洋特钢集团有限公司

Flaked tantalum powder and preparation method thereof

InactiveUS20190308247A1Improve leakage currentIncrease the speed of diffusionSolid electrolytic capacitorsTransportation and packagingPhysical chemistryThermal treatment

Provided are a flaked tantalum powder and method for preparation thereof; said flaked tantalum powder contains 300-1800 ppm of nitrogen, 10-100 ppm of phosphorus, and 1-40 ppm of boron. The flaked tantalum powder has high capacity and low leakage current, good puncture-resistance, and particularly outstanding high-frequency attributes. Doping with nitrogen during oxygen reduction is performed before three thermal treatments are carried out; the solution of performing three thermal treatments and a subsequent process improves the uniformity of distribution of elemental nitrogen and makes up for the deficiency of an oxide film, thereby increasing the pressure resistance of the product, and especially its high-frequency attributes.

Owner:NINGXIA ORIENT TANTALUM IND

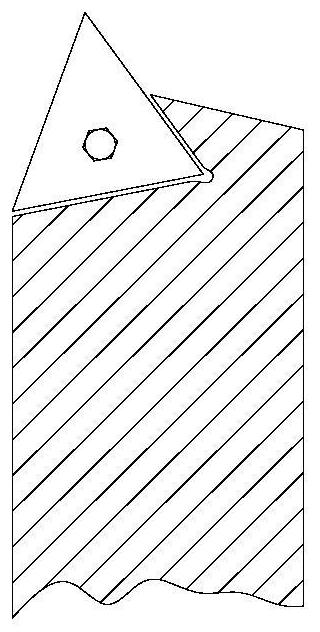

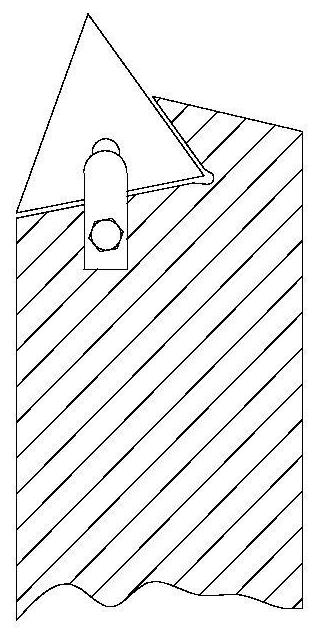

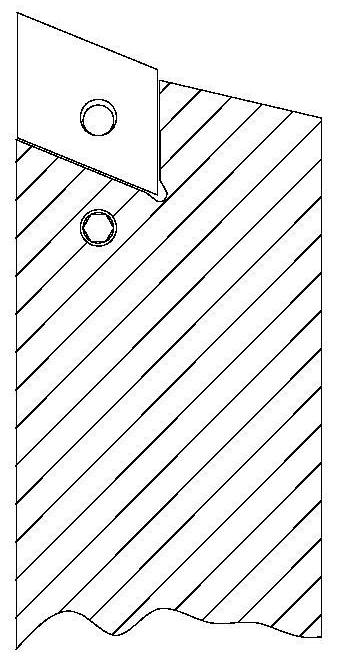

A CNC tool

The invention relates to a numerically controlled cutting tool, which belongs to the technical field of using machine-clamped cutting tools in mechanical processing. The CNC cutting tool includes a cutter body, a blade and a clamping part. The clamping part includes a fixing nut, a pressing block for fixing the blade, and a hook for fixing the blade; the front end of the cutter body is provided with a mounting through hole, and the mounting through hole It is used to insert the screw. The screw is equipped with a V-shaped groove. The opening position of the V-shaped groove matches the hook head. The blade and the knife shim under the blade pass through the hook head and lay flat in the knife groove of the knife body. A pressing block is inserted into the upper end of the screw rod, and a fixing nut is arranged on the pressing block. The invention provides clamping force on the blade from two directions through the hook head and the pressing block to ensure that the blade will not loosen during use and maximize the service life of the tool. Compared with the previous method of clamping the blade with a single clamping force, the Under the same material and cutting environment, the service life of the tool is extended by two to three months on average, which significantly improves the service life of the tool and reduces the cost of the tool in machining.

Owner:NANJING MEISHAN METALLURGY DEV

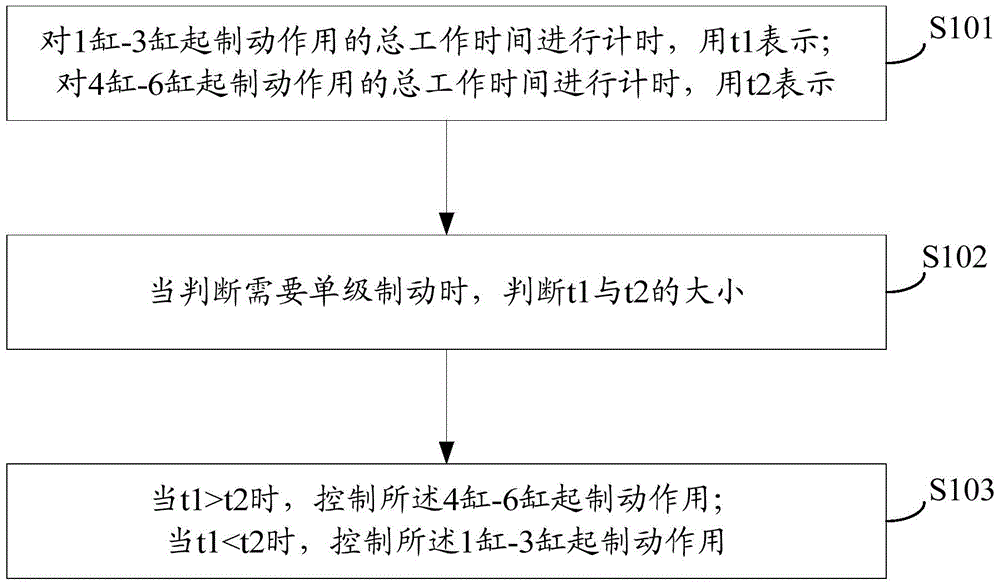

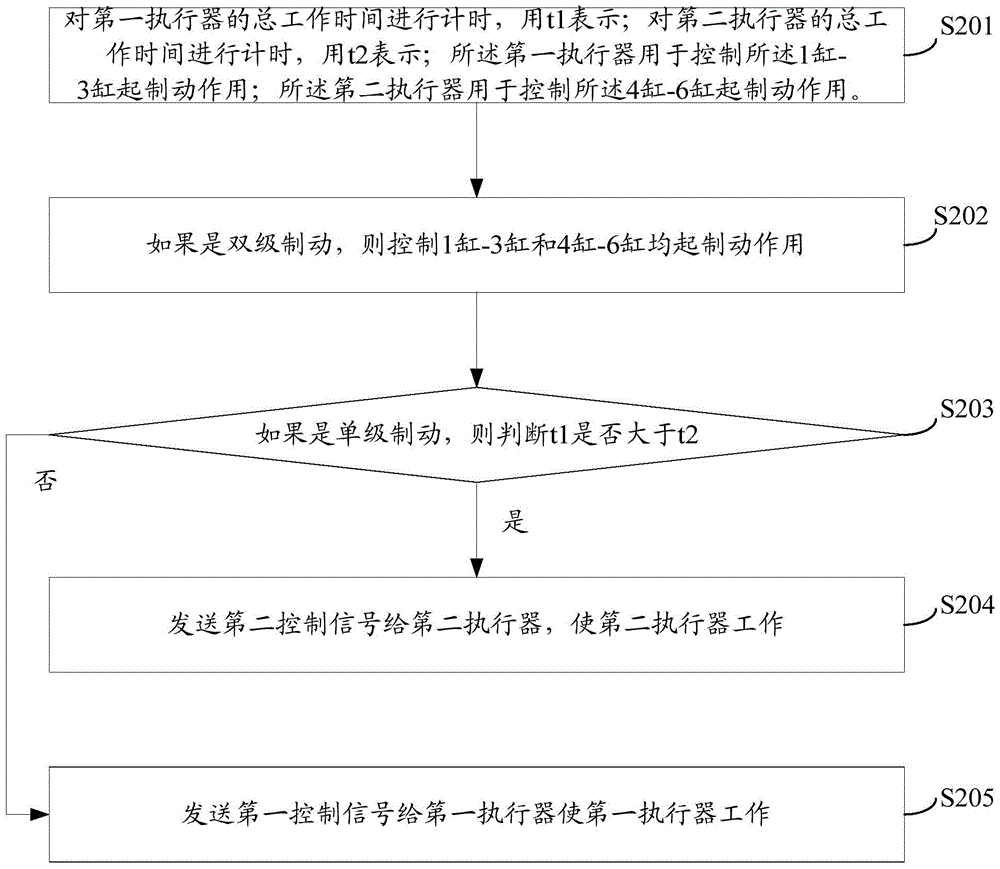

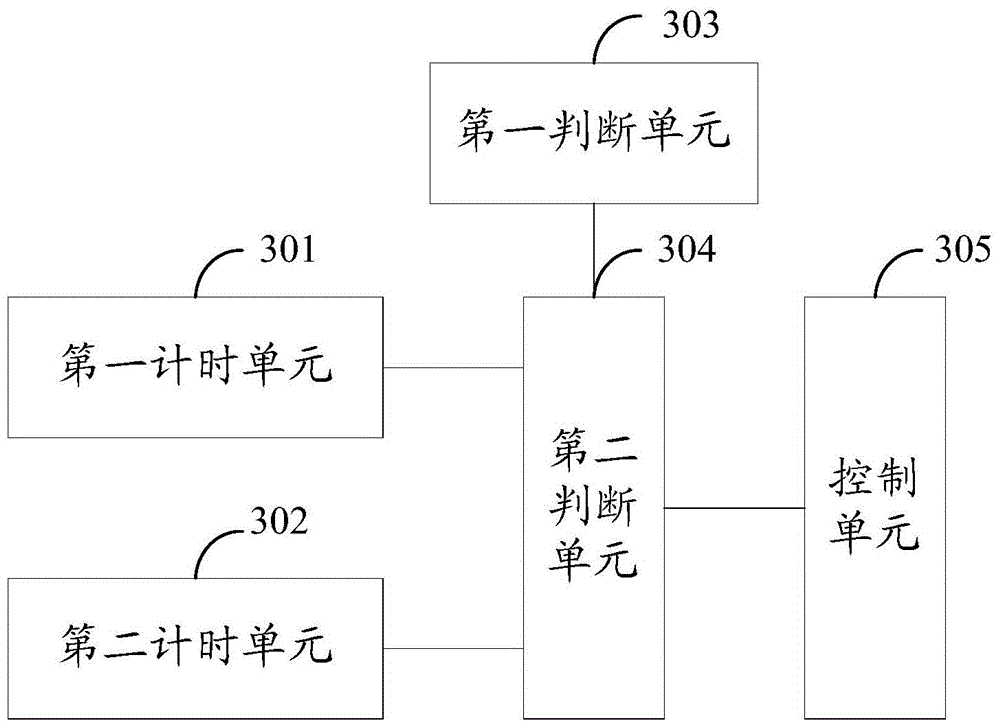

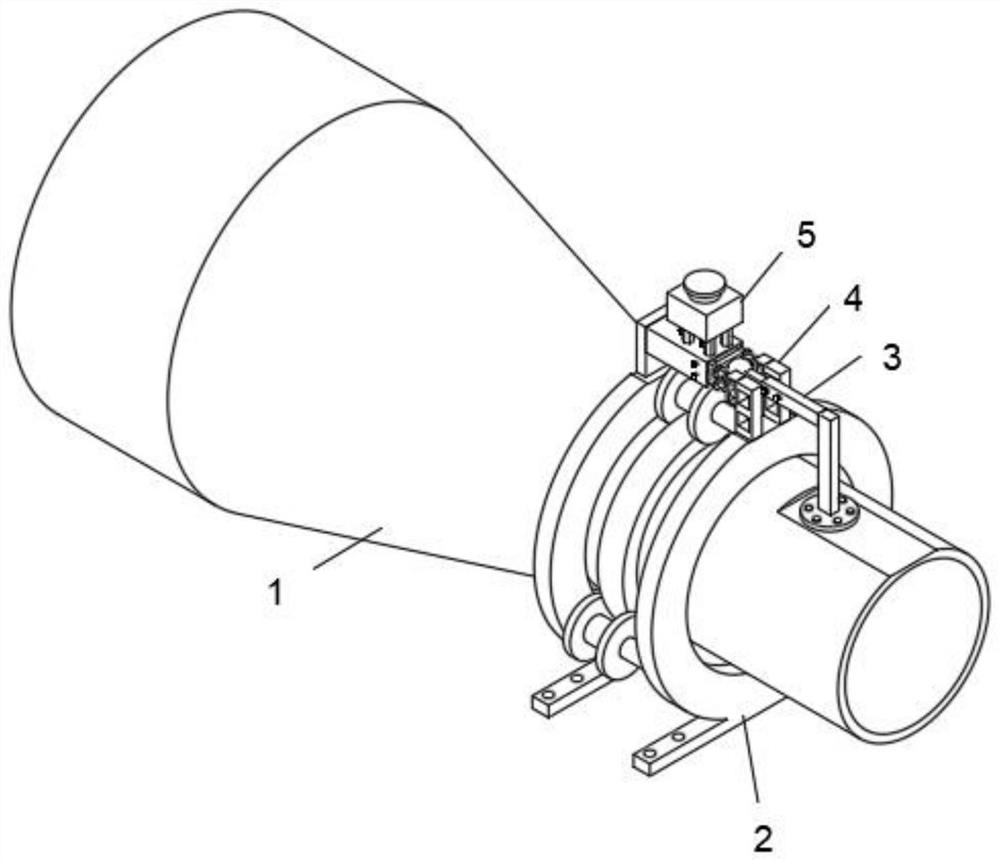

Method, device and system for controlling diesel engine compression release brake

ActiveCN104121108BBadly wornImprove reliabilityElectrical controlMachines/enginesWork periodSingle stage

The invention provides a diesel engine compressing, releasing and braking control method, device and system. The method comprises the steps that the total braking working time of a first cylinder, a second cylinder and a third cylinder is counted and is represented with t1; the total braking working time of a fourth cylinder, a fifth cylinder and a sixth cylinder is counted and is represented with t2; when single-stage braking is needed, the relationship between t1 and t2 is judged; when t1 is larger than t2, the fourth cylinder, the fifth cylinder and the sixth cylinder are controlled to play a braking role; when t1 is smaller than t2, the first cylinder, the second cylinder and the third cylinder are controlled to play a braking role. The total working time of the first cylinder, the second cylinder and the third cylinder is compared with the total working time of the fourth cylinder, the fifth cylinder and the sixth cylinder to judge that during one-stage braking, the set of cylinders corresponding to the short total working time is used for playing the role of braking, and the two sets of cylinders can play the role of braking alternately. According to the control method, the two sets of cylinders can be utilized in a balanced mode, and the situation that one set of cylinders are used frequently while the other set of cylinders are used less cannot occur. Thus, working reliability of a whole diesel engine can be improved.

Owner:WEICHAI POWER CO LTD

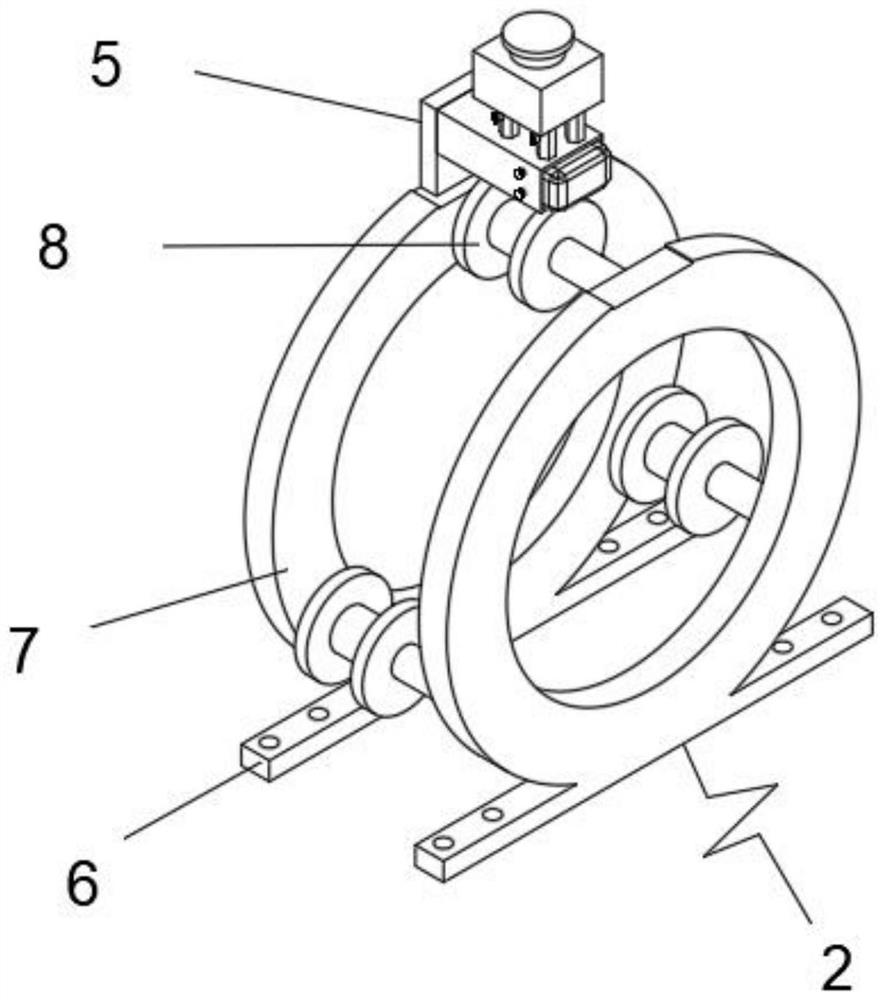

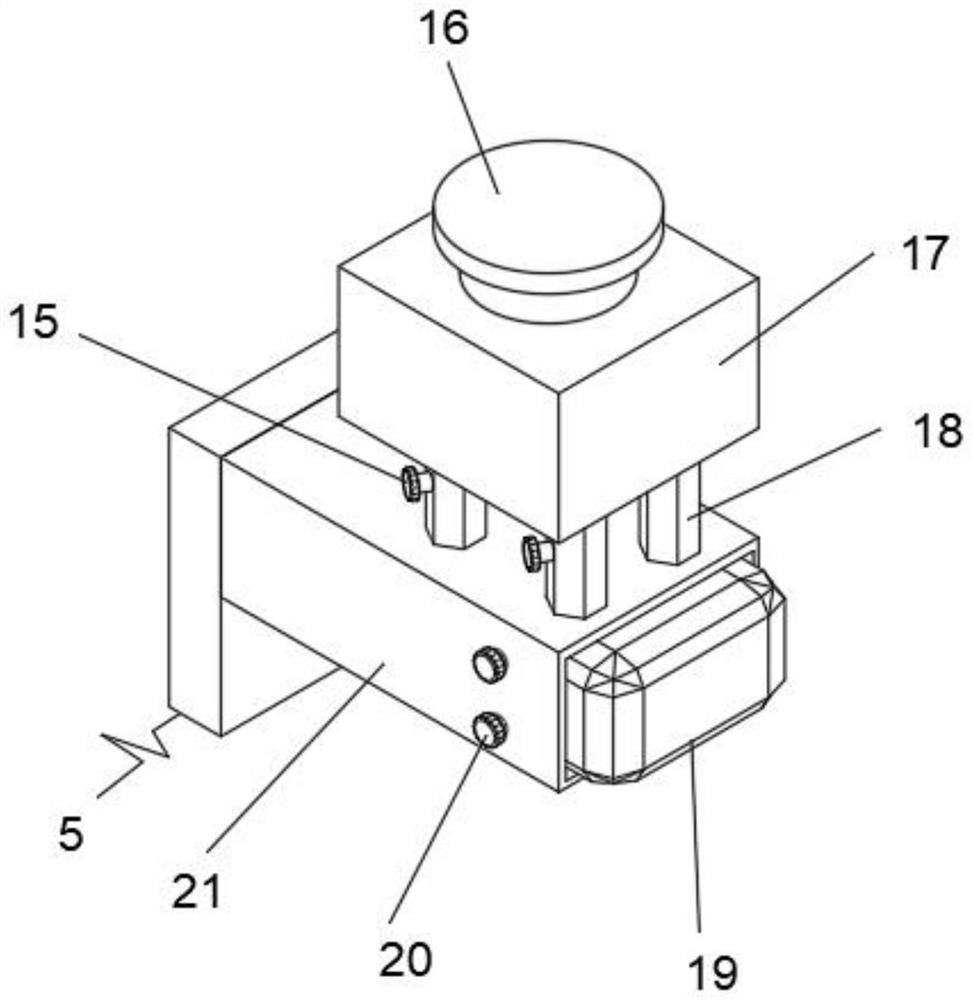

Butter adding device for supporting ring of concrete truck

The invention relates to the field of concrete transport vehicles, in particular to a butter adding device for a supporting ring of a concrete transport vehicle, and aims to solve the technical problem that a hopper needs to continuously rotate in the process that the concrete transport vehicle transports concrete, so that the concrete in the concrete transport vehicle is prevented from being condensed. In the rotating process of the hopper, a rotating supporting clamping ring on the hopper is prone to abrasion. Comprising a fixing plate, supporting rings and rotating supporting shafts, the number of the supporting rings is two, the fixing plate is fixedly connected to the bottom ends of the supporting rings, the rotating supporting shafts are evenly and rotationally installed between the supporting rings, and a rotating supporting clamping ring is rotationally clamped and fixed between the middles of the rotating supporting shafts. The technical scheme has the beneficial effects that lubricating oil can be automatically adjusted on the rotary supporting clamping ring in the rotating process of the charging barrel.

Owner:岳阳华铭混凝土有限公司

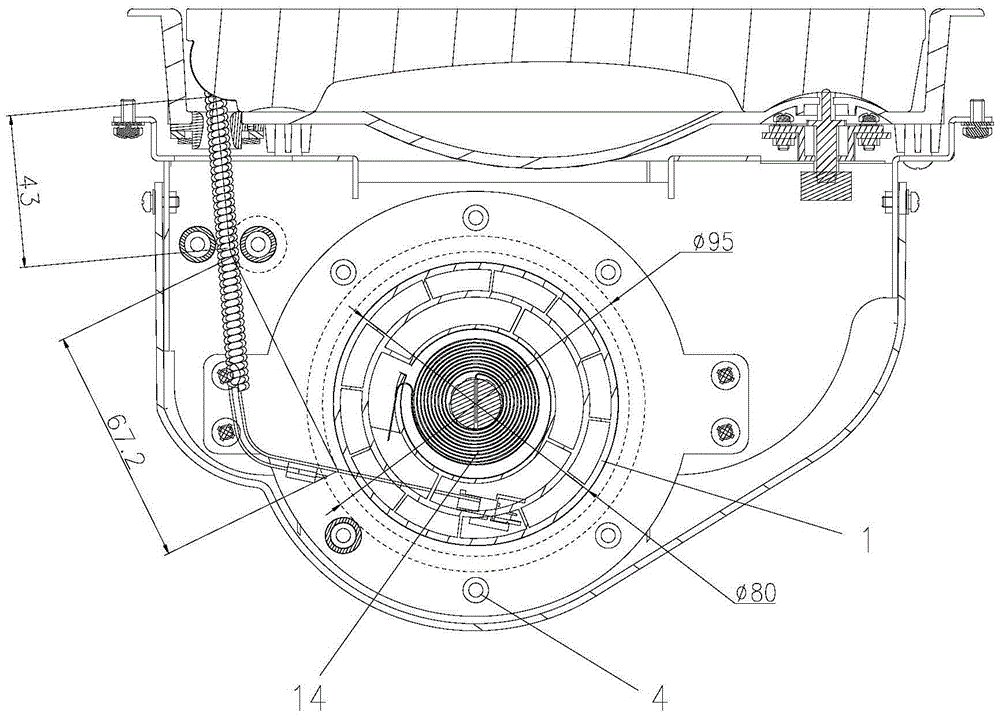

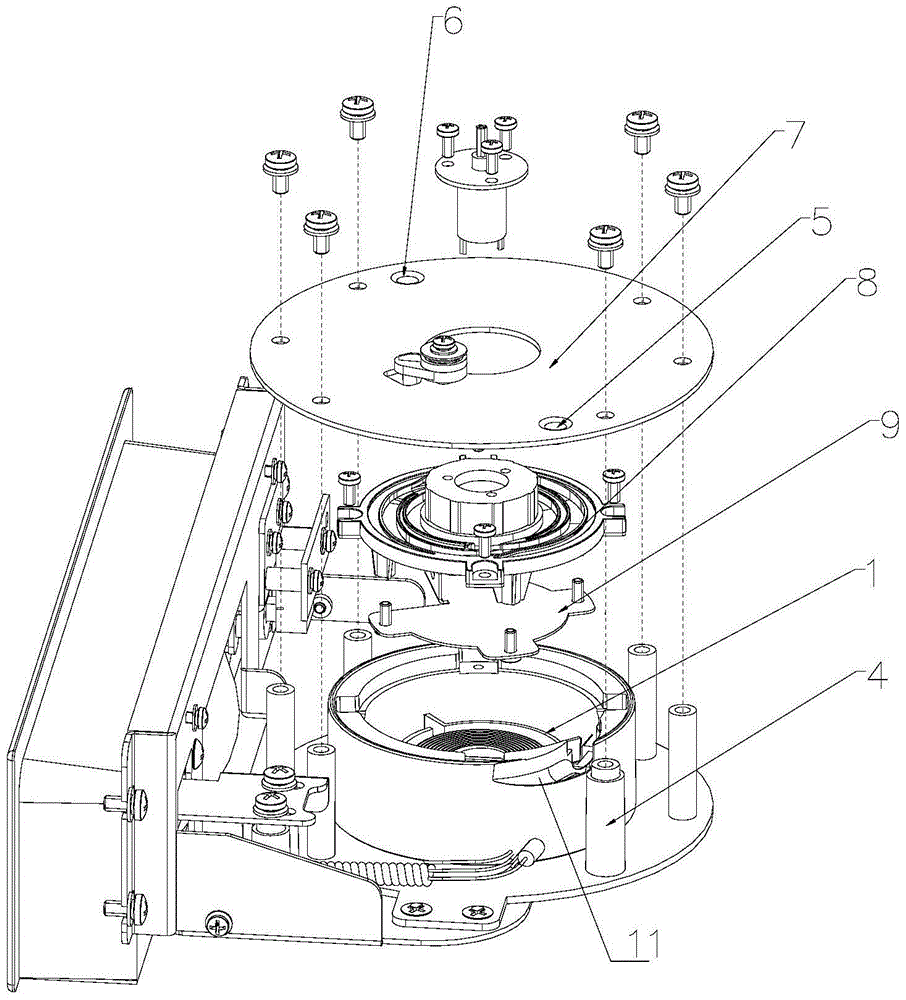

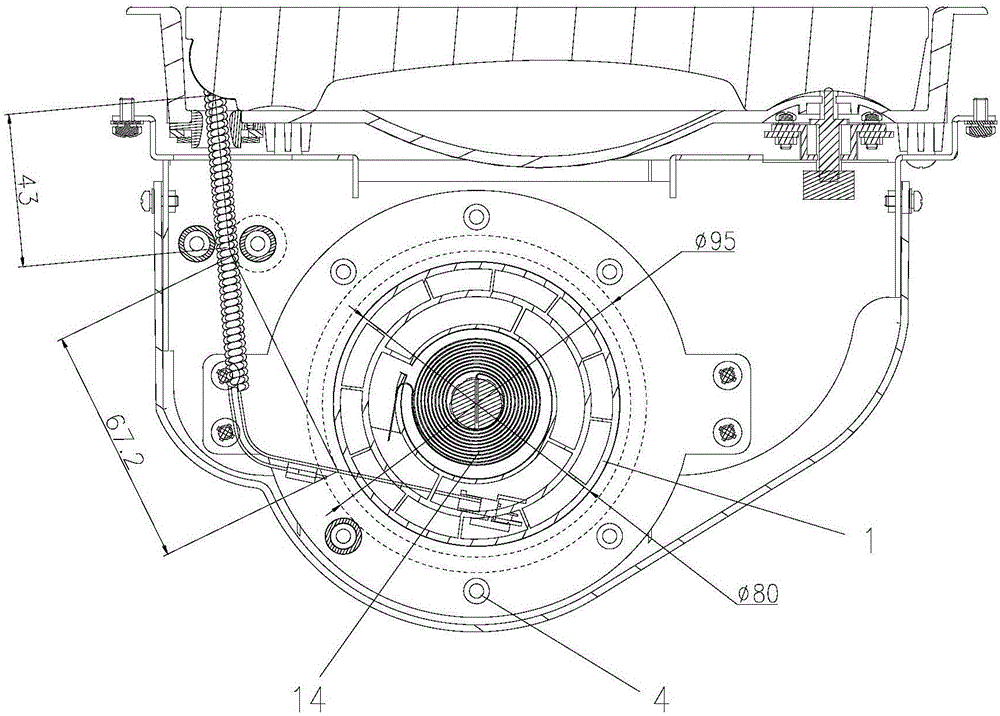

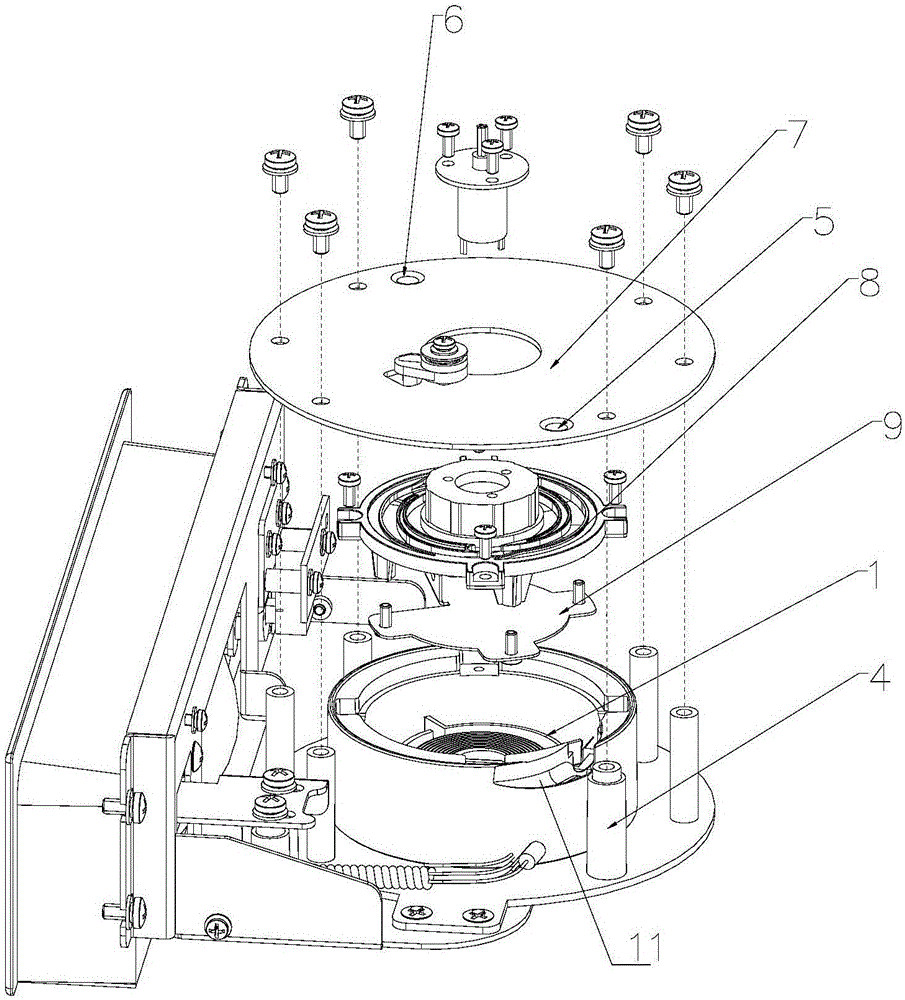

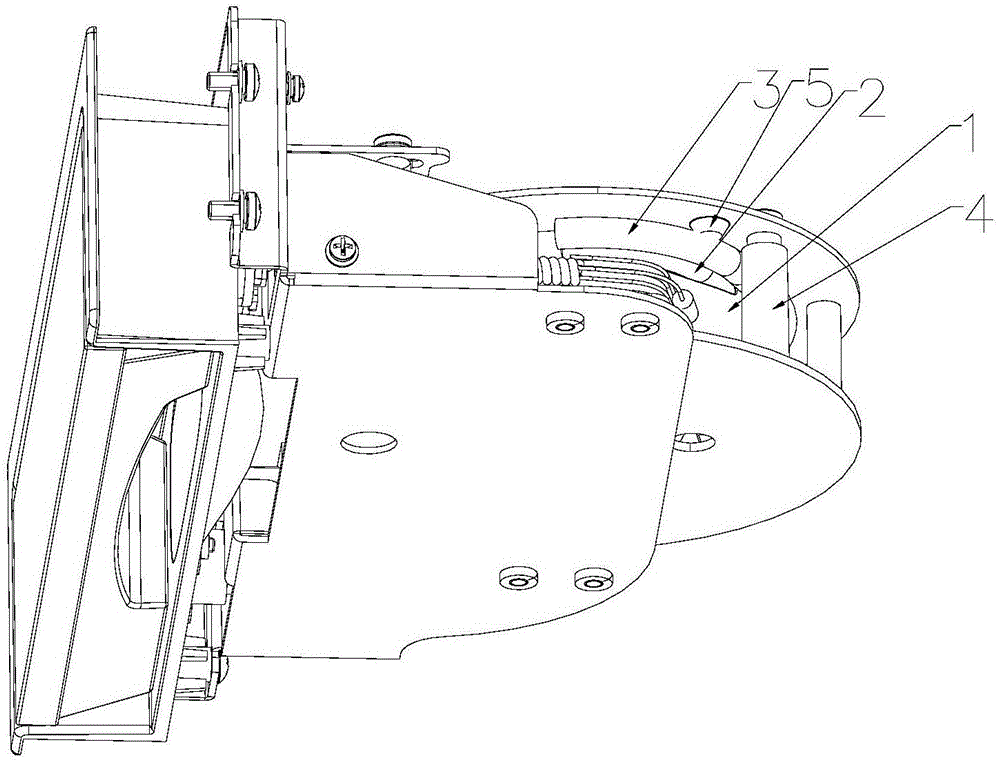

Take-up structure Microphone wire winding and automatic reset structure

The invention discloses a cord winding and automatic resetting structure of a take-up structure microphone cord. The cord winding and automatic resetting structure comprises a take-up structure assembly and the microphone cord. The take-up structure assembly comprises a take-up structure upper plate (7), a going barrel and pressing rivet nut columns (4). The going barrel comprises a coil spring seat upper cover (8), a coil spring seat (1) and a microphone cord pressing sheet (9). A guide groove (11) is formed in the top of the coil spring seat (1). Only one microphone cord can be contained on the cross section between a circle formed by the pressing rivet nut columns around the coil spring seat (1) and a POM shaft sleeve (4) and the coil spring seat (1), wherein only the pressing rivet nut column at the cord outlet position of the take-up structure assembly is provided with the POM shaft sleeve. A first resetting convex hull (5) and a second resetting convex hull (6) are arranged on the side, facing the coil spring seat (1), of the take-up structure upper plate (7). According to the cord winding and automatic resetting structure of the take-up structure microphone cord, the microphone cord is prevented from being staggered or overlapped, the microphone cord is drawn, pulled and recycled smoothly when used by a user, and user experience is good.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

Absorbent structure comprising release structure

An absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet, and an absorbent structure positioned in between said topsheet and said backsheet, wherein the absorbent structure comprises an absorbent core positioned in between the topsheet and the backsheet, a release structure being positioned in fluid communication with the absorbent core, said absorbent core comprising little to no cellulose fibers and / or fluff pulp and said absorbent core comprising an absorbent polymer material for absorbing and permanently holding fluids received from the topsheet and the release structure, wherein said release structure comprises at least one fibrous substrate structure having the capacity to receive and temporarily hold the fluids in proximity to the absorbent core so that the fluids can subsequently be transferred and released to and absorbed by the absorbent core.

Owner:DRYLOCK TECHNILOGIES NV

Angle cock for train braking

PendingCN113415306AHas an initial deceleration effectIncrease contact frictionAerodynamic brakesEngineeringEddy current

The invention relates to the technical field of braking equipment and discloses an angle cock for train braking. The angle cock for train braking comprises a cock body, wherein one side of the cock body is integrally molded with a vertically arranged body, and an inner cavity of the cock body and the vertically arranged body are matched and intersected to form a fixed sleeve which is provided with a sealing seat. According to the angle cock for train braking, airflow generated in the train running process of a fan drives a rotating shaft to rotate to drive a magnet disc to rotate, a first thread cuts a magnetic field of the magnet disc to generate eddy current to generate heat, heat is conducted to the top of a plug plate, an air bag is heated and expanded to drive the plug plate to move downwards, and an axial through hole of a sealing seat can be opened; when the cock is forgotten to be opened before a train is started, the cock can be automatically opened, a heat conduction rod moves downwards to drive a protruding block to be matched with a braking groove, a first thread is meshed with a second thread, an air bag is cooled and contracted, the heat conduction rod is limited by the braking groove, and under the elastic force effect of a first spring, a plug plate cannot rise and is automatically closed; it is guaranteed that the cock can be kept open in the train running process.

Owner:曾翠花

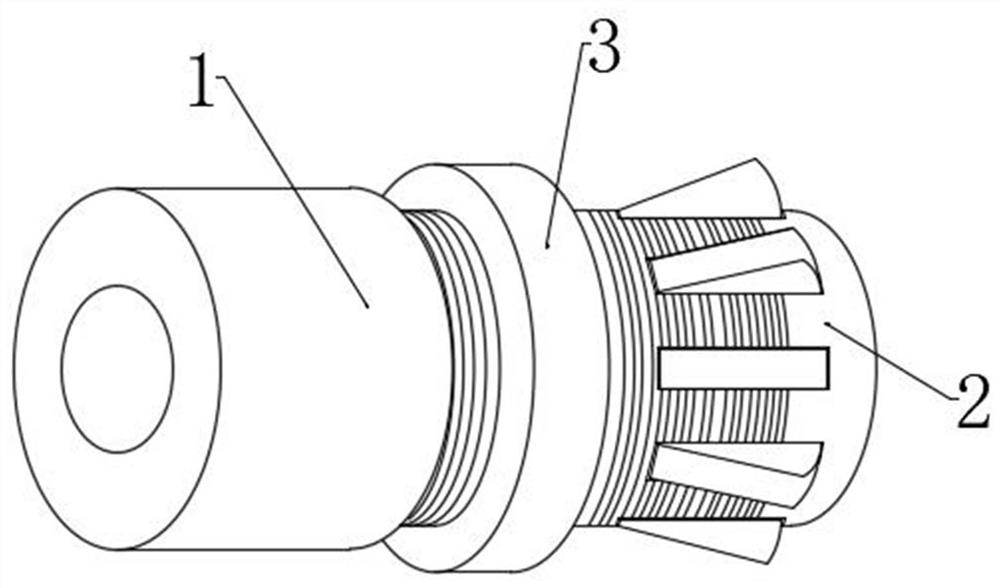

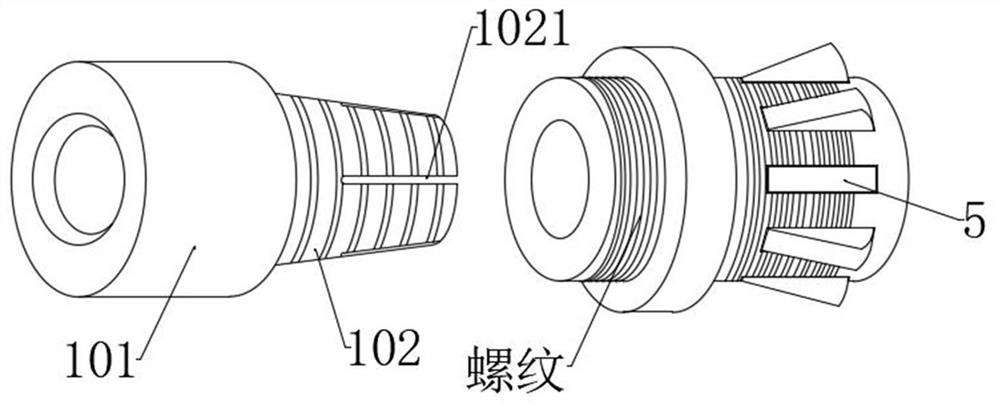

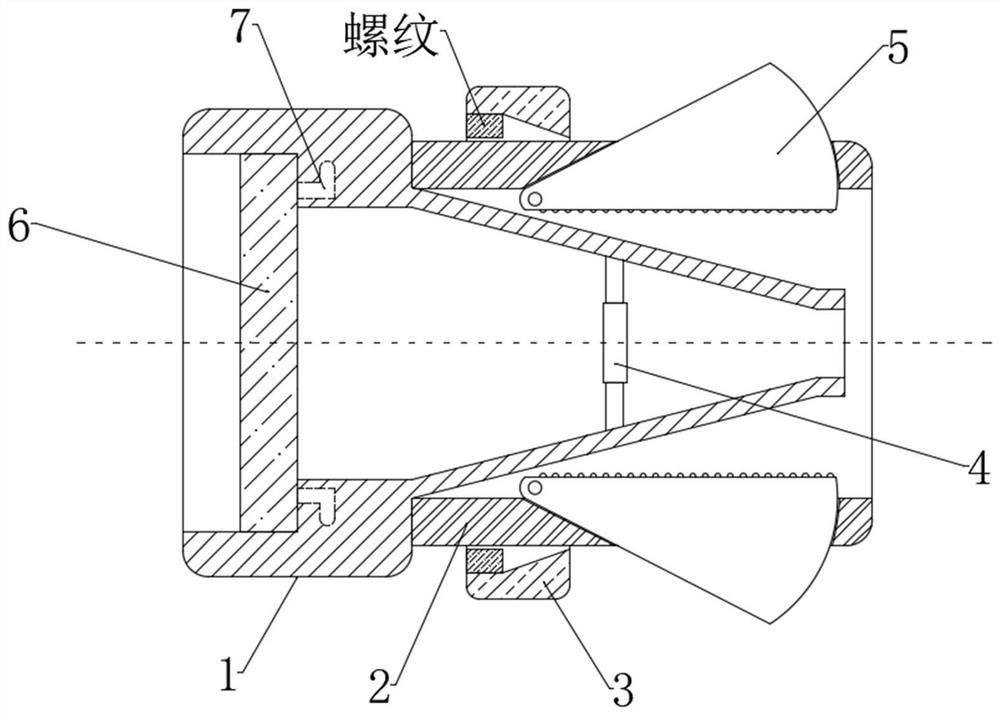

A self-adaptive hose joint and its use method

ActiveCN113483178BEffectively absorbs impactEnsure a stable connectionPipe elementsHose connectionsWater hammerIndustrial engineering

The invention discloses an adaptive hose joint and a use method thereof, which belong to the field of pipe joints. The tapered self-adaptive connecting section is adapted to the hose, which can meet the connection requirements of hoses with different calibers and effectively improve the joint performance. Adaptability, by rotating the compression nut, the fan-shaped compression block is rotated inward, so that the compression block presses the hose tightly on the adaptive connection section, thereby effectively improving the stable connection between the joint and the hose. Partition strip-shaped openings are set on the adaptive connecting section to make it have a certain degree of elasticity, which can effectively absorb the impact force of the adaptive connecting section due to the water hammer effect, and increase the outward expansion tension of the adaptive connecting section through impact absorbing parts And limit its inward shrinkage, so that when the adaptive connection section is impacted and expands outward due to the water hammer effect, the clamping force on the hose can be effectively improved, and the stable connection between the joint and the hose can be further ensured.

Owner:南通市协通精密机械制造有限公司

Cord winding and automatic resetting structure of take-up structure microphone cord

The invention discloses a cord winding and automatic resetting structure of a take-up structure microphone cord. The cord winding and automatic resetting structure comprises a take-up structure assembly and the microphone cord. The take-up structure assembly comprises a take-up structure upper plate (7), a going barrel and pressing rivet nut columns (4). The going barrel comprises a coil spring seat upper cover (8), a coil spring seat (1) and a microphone cord pressing sheet (9). A guide groove (11) is formed in the top of the coil spring seat (1). Only one microphone cord can be contained on the cross section between a circle formed by the pressing rivet nut columns around the coil spring seat (1) and a POM shaft sleeve (4) and the coil spring seat (1), wherein only the pressing rivet nut column at the cord outlet position of the take-up structure assembly is provided with the POM shaft sleeve. A first resetting convex hull (5) and a second resetting convex hull (6) are arranged on the side, facing the coil spring seat (1), of the take-up structure upper plate (7). According to the cord winding and automatic resetting structure of the take-up structure microphone cord, the microphone cord is prevented from being staggered or overlapped, the microphone cord is drawn, pulled and recycled smoothly when used by a user, and user experience is good.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

Make-up composition comprising a hydrolysate of theobroma cacao l beans and at least one prebiotic and a probiotic

PendingUS20210212925A1Improve homogeneityReduce firmnessCosmetic preparationsMake-upCOCOA BEANKeratin protein

The present invention relates in particular to a cosmetic composition for making up keratin materials, in particular the skin, the lips or the eyes, preferably the skin, comprising, in a physiologically acceptable medium, at least: a) a hydrolysate of Theobroma cacao L beans, b) a prebiotic and a probiotic, and c) one or more coloring material(s).

Owner:LVMH RECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com