Carpets with improved fuzz-resistance

a technology of fuzz resistance and carpet, applied in the field of carpets, can solve the problems of marked loss of tuft lock or tuft bind, deficiency of cured binders, and impracticality of reprocessing, and achieve the effects of improving fuzz resistance, good retention of tuft bind strength, and improving bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

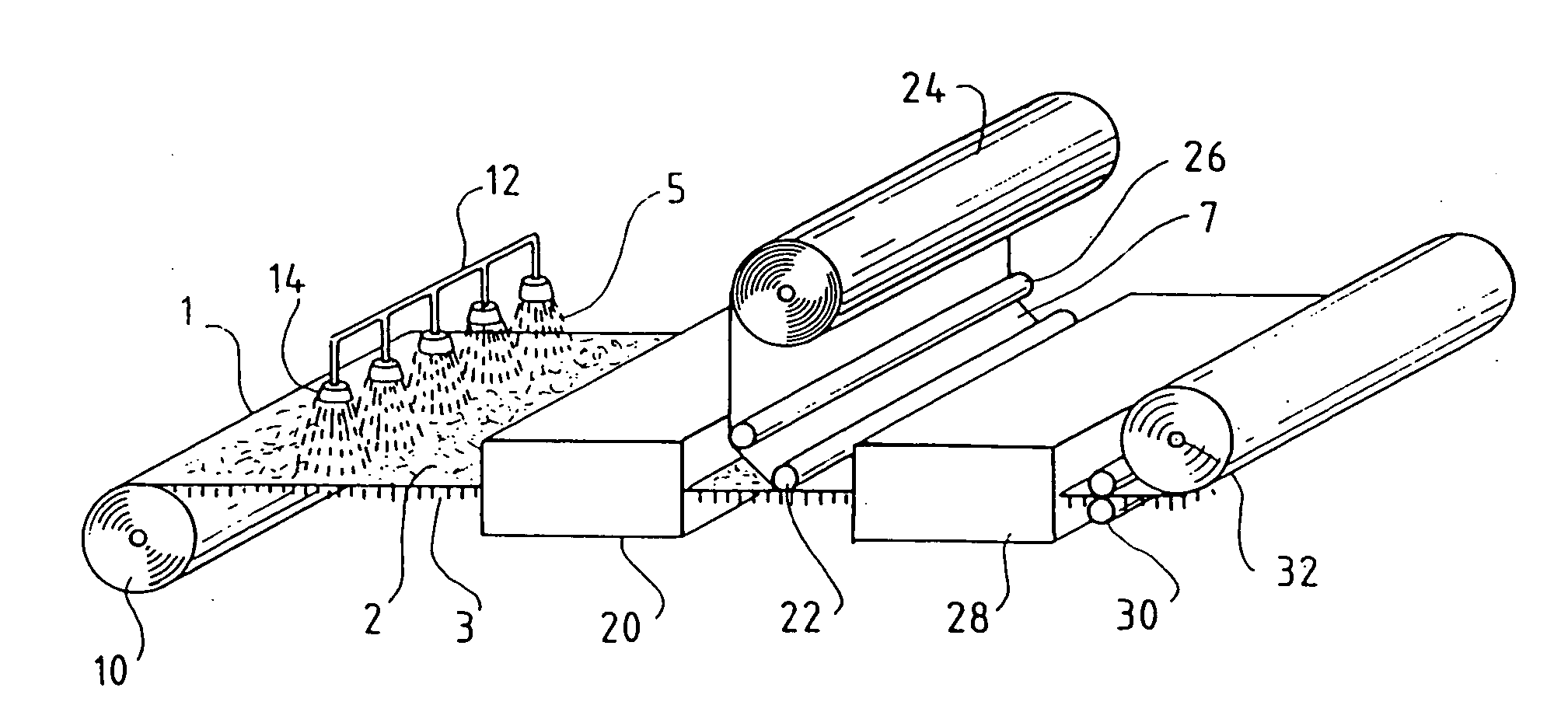

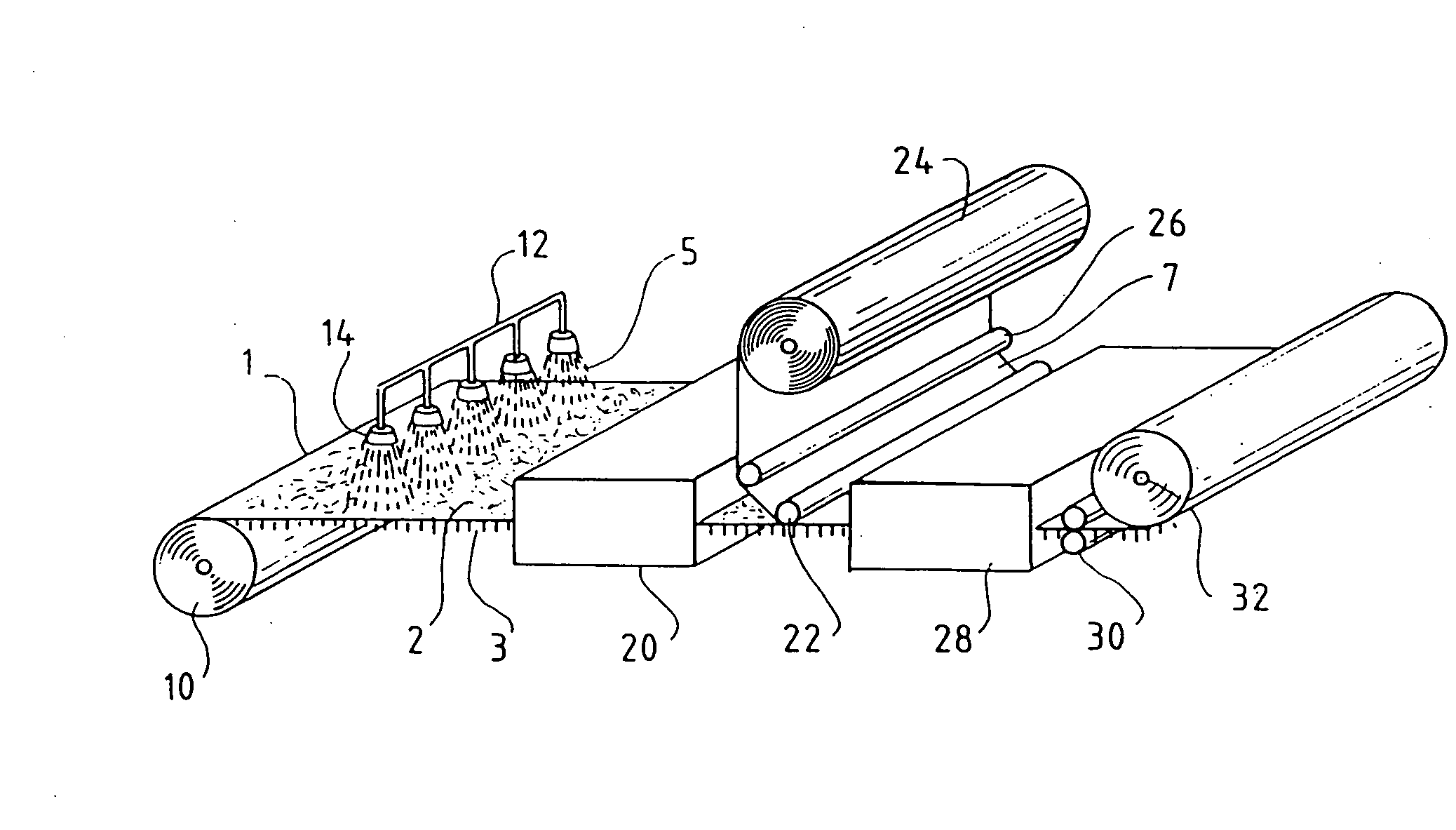

[0133] A tufted carpet is prepared on a carpet line as illustrated in the drawing operated at a line speed of 50 feet per minute (15 m / min). The tufted backing has a 152 inch wide primary backing woven from polypropylene tapes in a plain weave construction with 24 warp tapes per inch by 15 weft tapes per inch. The primary backing is tufted in a straight stitch pattern with 4000 denier, cabled, heatset nylon BCF face yarn to form a cut pile with 8 stitches per inch on the stitched side, ⅛ gauge and face yarn weight of 42 osy.

[0134] The stitch bind composition is a 15 wt % solids content, 3.3 cps, aqueous dispersion of solid ethylene acrylic acid copolymer prepared by diluting a commercially available ethylene acrylic acid copolymer dispersion in ammonia water, designated MichemPrime 4983-30R. The dispersion, before dilution, has nominal polymer solids content of 30 wt %, viscosity of 1000 cps and its ethylene-acrylic acid copolymer has nominal acrylic acid unit content of 20 wt % an...

example 2

[0139] A tufted carpet is prepared on a carpet line as illustrated in the drawing operated at a line speed of 30 feet per minute (9 m / min).

[0140] The tufted backing has a primary backing fabric as in Example 1 to which had been needled a thermoplastic binder in the form of a 3 osy continuous filament nonwoven fabric prepared according to U.S. Pat. No. 5,173,356. The filaments of the nonwoven fabric were composed of a linear low density polyethylene resin having nominal MI of 105 g / 10 min, density of 0.930 g / cc and melting point of 125° C. The nonwoven fabric is needled to the primary backing with 400 needle punches per square inch such that a web is disposed on one side of the backing and a plurality of filaments from the web penetrate to the other side of the backing.

[0141] The primary backing with affixed binder is tufted in a stepover stitch pattern with 5000 denier nylon BCF face yarn to form a ¼ inch high, loop pile with 8 stitches per inch and ⅛ gauge. Pile weight is 28 osy....

examples 3-37

[0148] In the following examples, carpet samples were prepared from various materials and Fuzz Ratings of loop pile samples and Tuft Bind strengths of all samples were determined. Carpet samples were made according to the following general procedure.

[0149] Tufted primary backings with various face yarns and primary backing fabrics, as described in detail in connection with the specific examples in which they were used, were prepared on a laboratory scale tufting machine or obtained from commercial sources. Additional backings, or composites thereof with thermoplastic binders, were also used, again as described in connection with specific examples in which they were used.

[0150] Samples of tufted primary backings and of additional backings or additional backing-thermoplastic binder composites were cut into rectangles 18 inches long and 12 inches wide, with the longer dimension in the machine direction. Stitch bind compositions in the form of aqueous dispersions or emulsions were pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| MI | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com