Grooving machine for carton production

A slotting machine and carton technology, which is used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of low applicability, complicated operation, and inability to slot carton boxes of different sizes, and achieves good fixing effect. , Simple operation and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

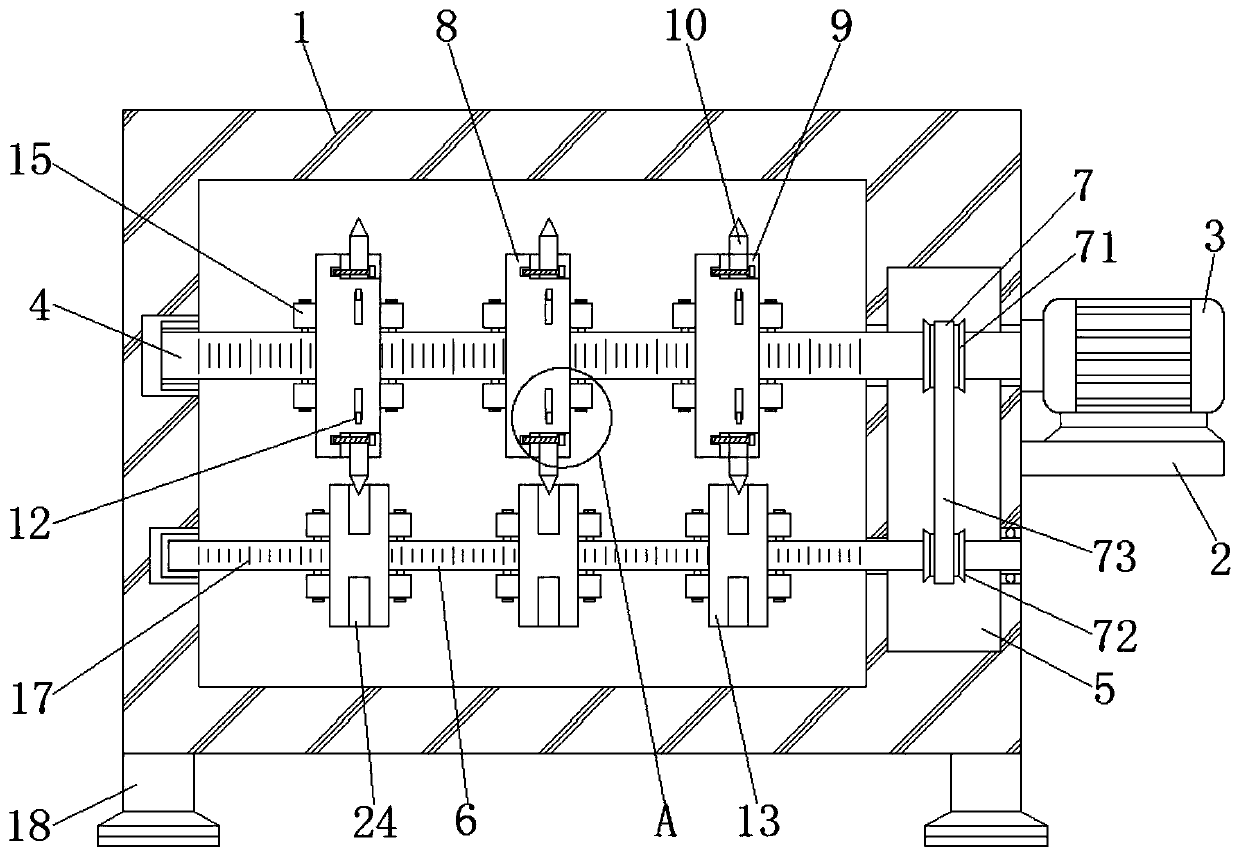

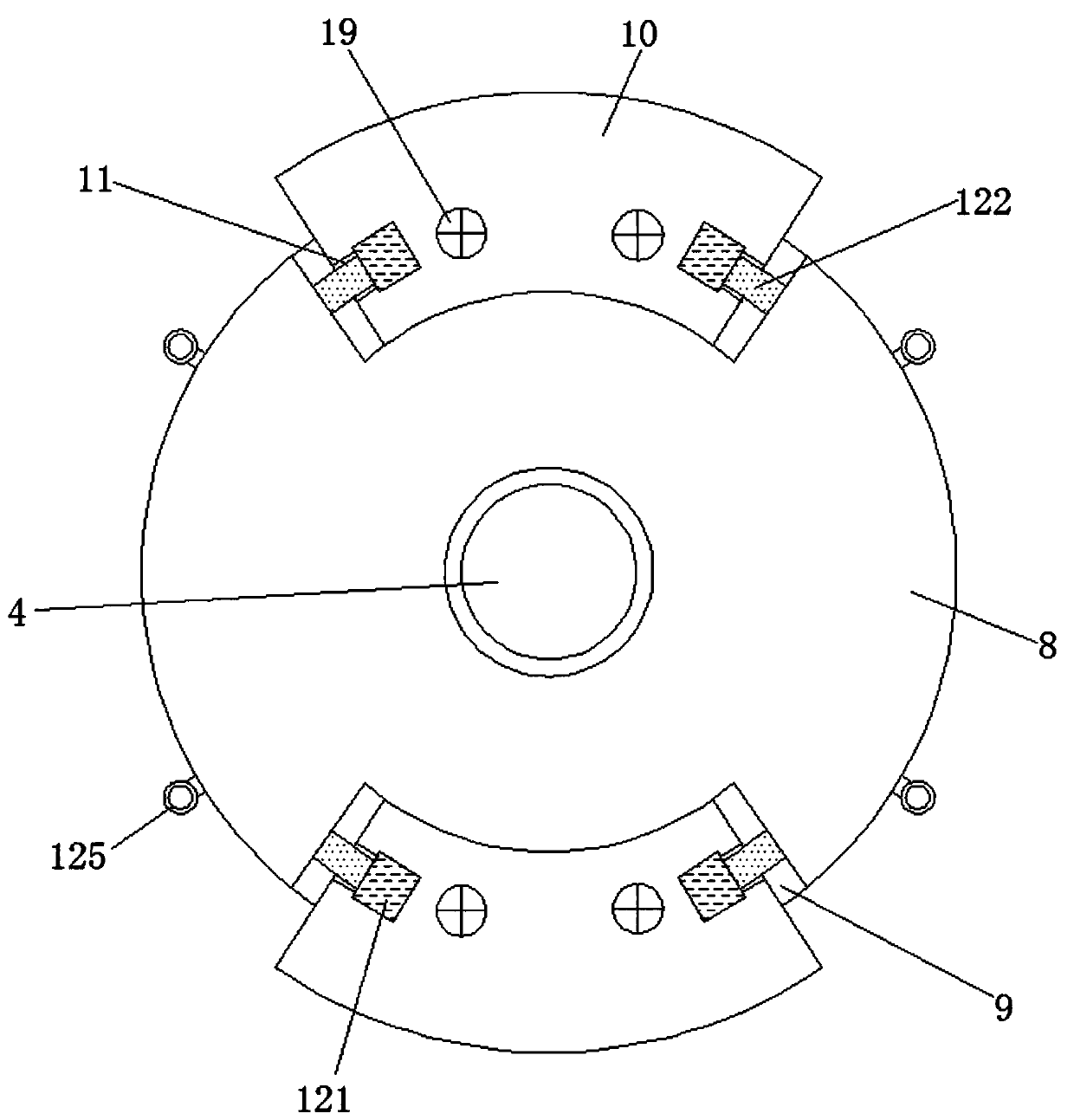

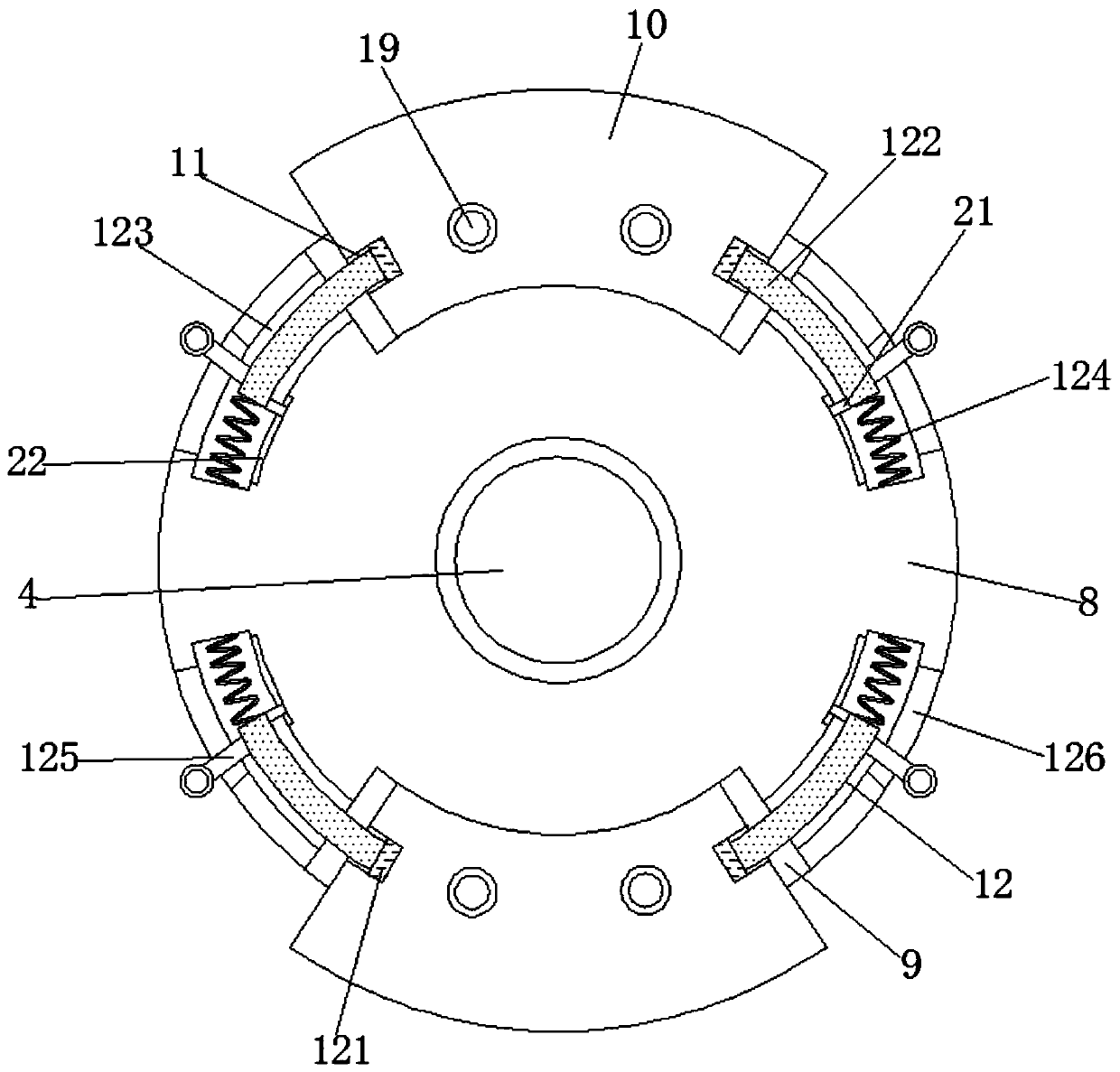

[0037] see Figure 1-6, a slotting machine for carton production, comprising a frame 1, a support plate 2 is fixedly connected to the right side of the frame 1, a drive motor 3 is fixedly connected to the top of the support plate 2, the model of the drive motor 3 is YY5612, and the drive motor 3. The upper crimping roller 4 is fixedly connected to the left side of the output shaft. A cavity 5 is opened on the left side of the front of the frame 1. The left end of the upper crimping roller 4 passes through the frame 1 and the cavity 5 in sequence and extends to the frame 1. Inside, the left side of the inner wall of the frame 1 is embedded with a first bearing, and the end of the upper crimping roller 4 away from the drive motor 3 is fixedly connected with the inner ring of the first bearing, and the inner wall on the right side of the cavity 5 is embedded with a second bearing. Bearing, the inner ring of the second bearing is fixedly connected with the lower crimping roller 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com