Method, device and system for controlling diesel engine compression release brake

A technology for brake control and diesel engine, applied in engine control, electrical control, fuel injection control, etc., can solve problems such as cylinder wear and seriousness, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

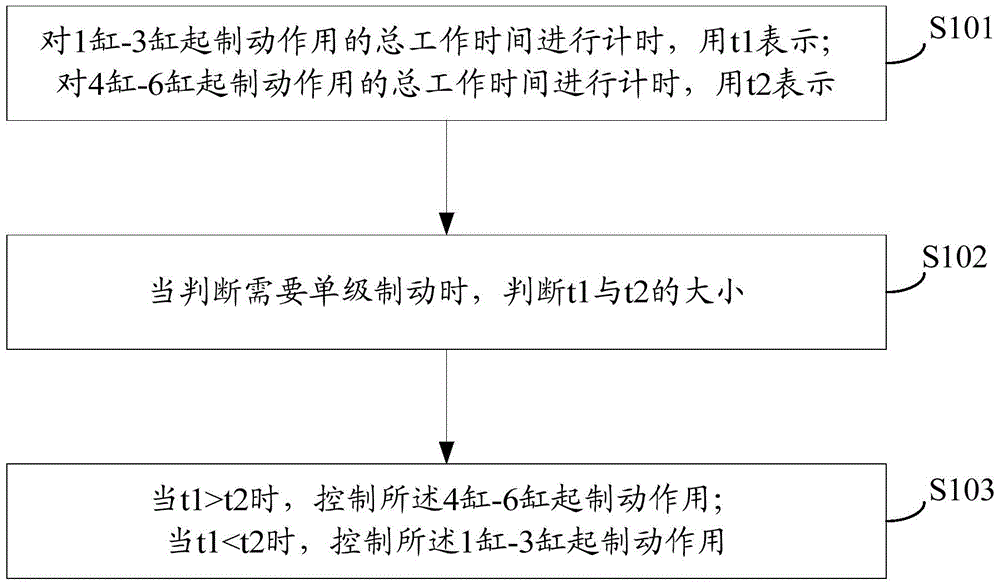

[0060] see figure 1 , which is a flow chart of Embodiment 1 of the diesel engine compression release braking control method provided by the present invention.

[0061] The diesel engine compression release braking control method provided in this embodiment includes the following steps:

[0062] S101: Timing the total working time of cylinder 1-3 for braking, expressed by t1; timing the total working time of cylinder 4-6 for braking, expressed by t2;

[0063] It should be noted that, in this embodiment, a diesel engine with 6 cylinders is used as an example for introduction. In the prior art, single-stage braking is 1-3 cylinders for braking, and double-stage braking is 1-6 cylinders. The cylinder acts as a brake. However, in the embodiment of the present invention, the working hours of cylinders 1-3 and cylinders 4-6 are timed respectively, and which group will work when the next single-stage braking is determined according to the working hours of the two groups of cylinders...

Embodiment 2

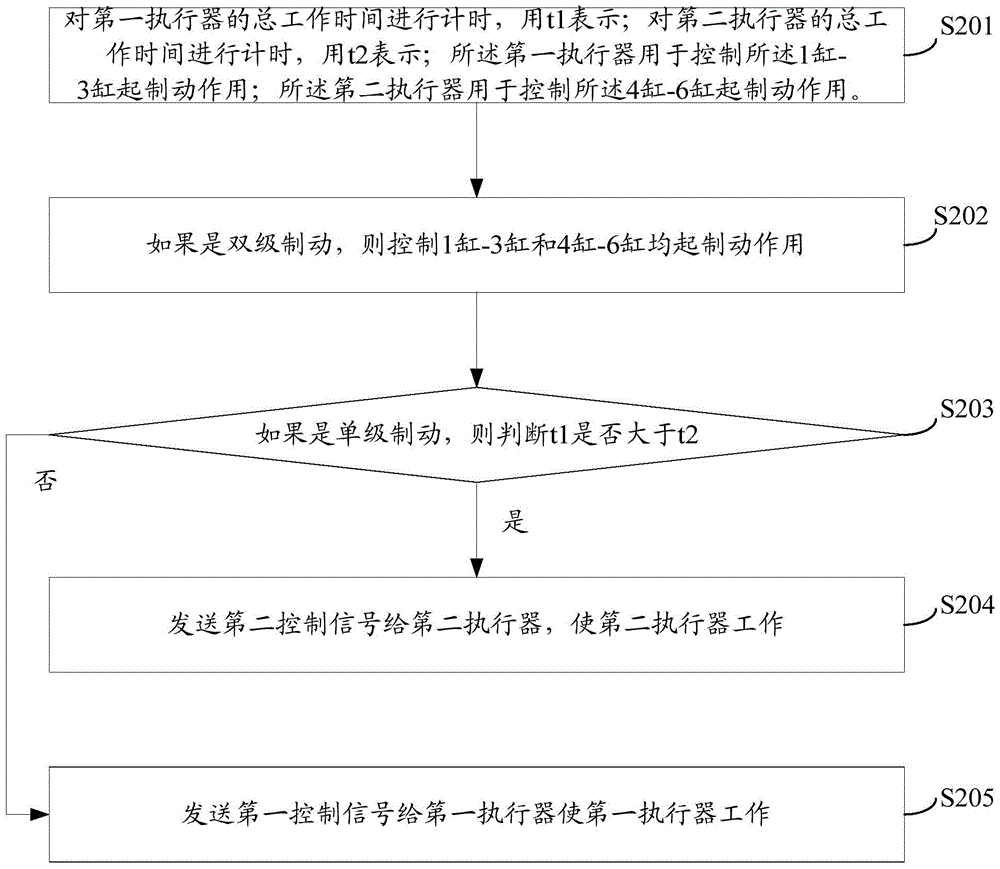

[0073] see figure 2 , which is a flow chart of Embodiment 2 of the diesel engine compression release braking control method provided by the present invention.

[0074] S201: Timing the total working time of the first actuator, represented by t1; timing the total working time of the second actuator, represented by t2; the first actuator is used to control the cylinder 1-3 Braking function; the second actuator is used to control the 4-6 cylinders to play a braking role.

[0075] It should be noted that since the first actuator is used to control cylinder 1-3 to perform braking work, the second actuator is used to control cylinder 4-6 to perform braking work. In fact, the first actuator and the second actuator are two solenoid valves, respectively the first solenoid valve and the second solenoid valve.

[0076] The opening and closing of the first solenoid valve and the second solenoid valve need to be controlled by the ECU sending a control signal. Therefore, when the ECU se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com