A self-adaptive hose joint and its use method

A hose joint, self-adaptive technology, applied in the field of pipe joints, can solve problems such as weak connection, laborious, poor adaptability, etc., to achieve the effect of improving clamping force, improving adaptability, and improving stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

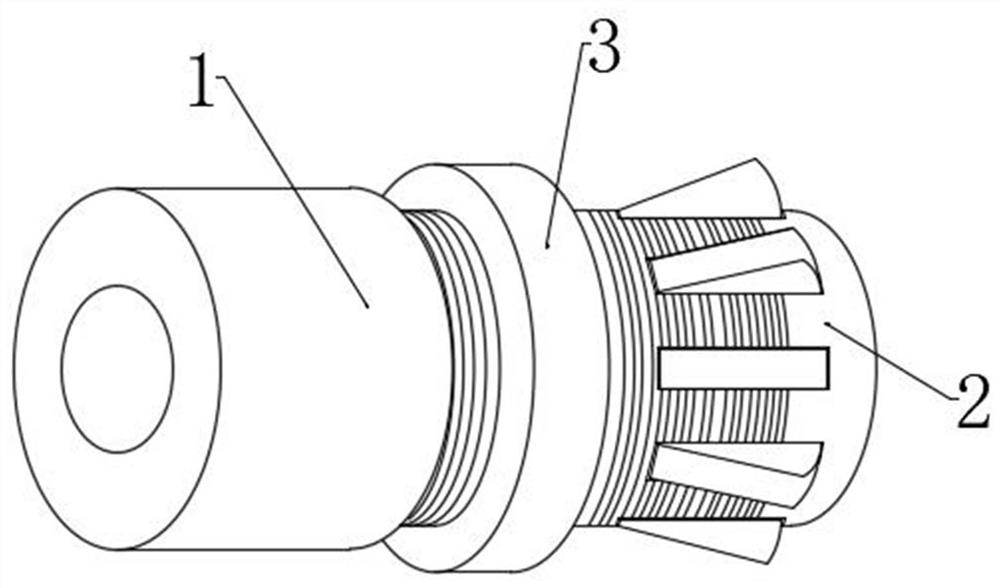

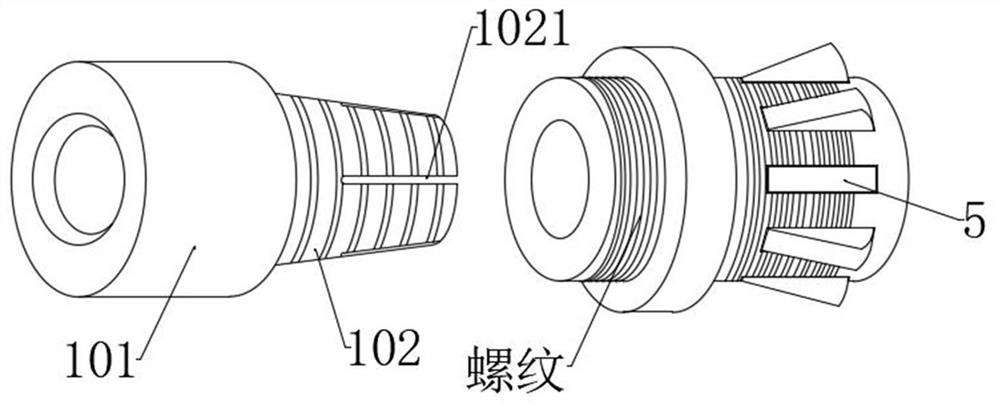

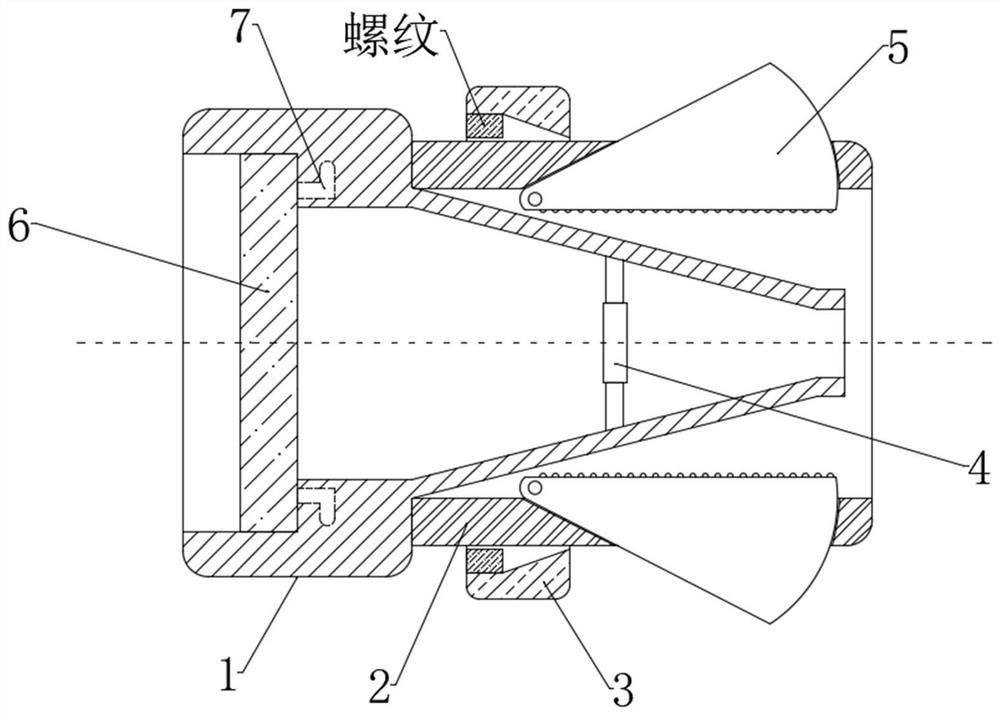

[0047] see Figure 1-10 , a self-adaptive hose fitting including connector 1, see figure 1 , 2 One end of the connector 1 is fixedly connected with the adjustment pipe 2 communicating with it, and the outside of the adjustment pipe 2 is covered with a compression nut 3 threadedly connected with it. The connecting section 102, the adaptive connecting section 102 is a conical structure, and the outer wall of the adaptive connecting section 102 is provided with a plurality of partition strip openings 1021 that divide it into multiple fan-shaped areas, and the adaptive connecting section 102 adopts corrosion-resistant High-strength material, and the length of the adaptive connection section 102 is greater than the length of the compression block 5, in order to increase the contact area between the hose and the outside of the adaptive connection section 102, thereby improving the compression effect of the compression block 5;

[0048] see image 3 , 5 , the inner wall of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com