Take-up structure Microphone wire winding and automatic reset structure

An automatic reset, microphone wire technology, applied in the field of wire take-up structure, can solve the problems of stuck wire, microphone core wire breakage, large stress when the microphone wire is bent, etc., to achieve a good user experience, low friction, pulling and recycling Smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

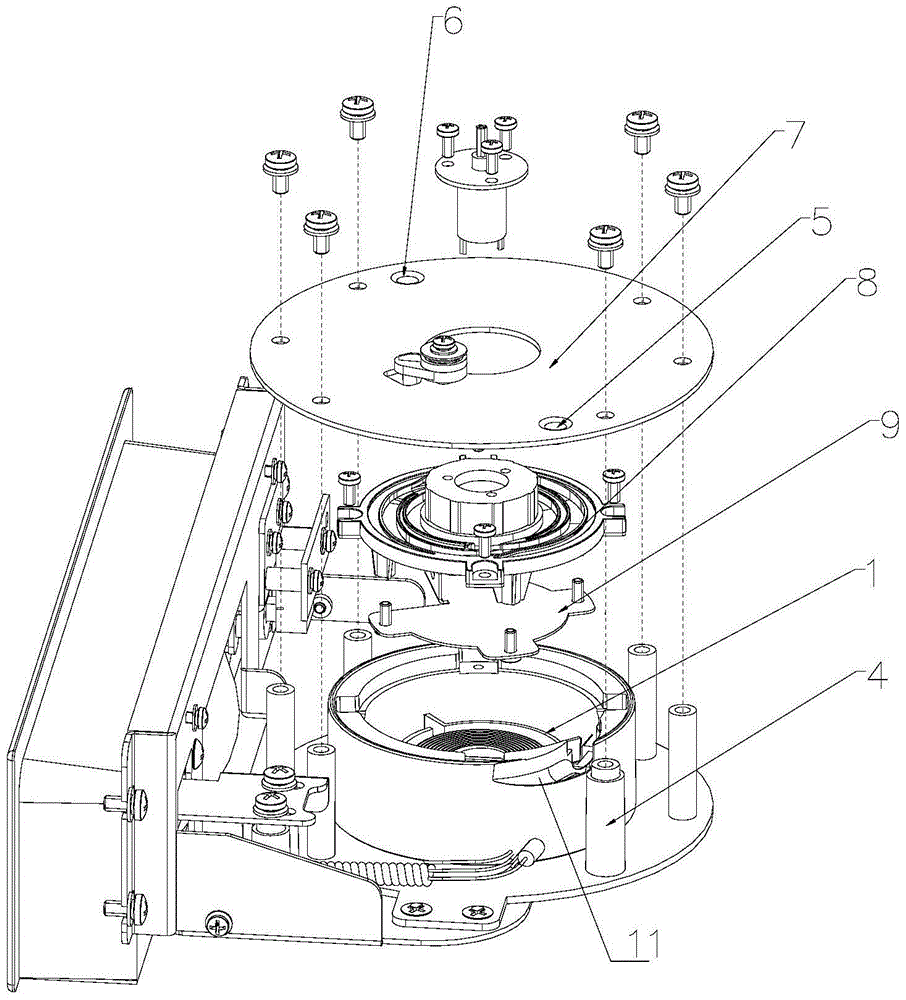

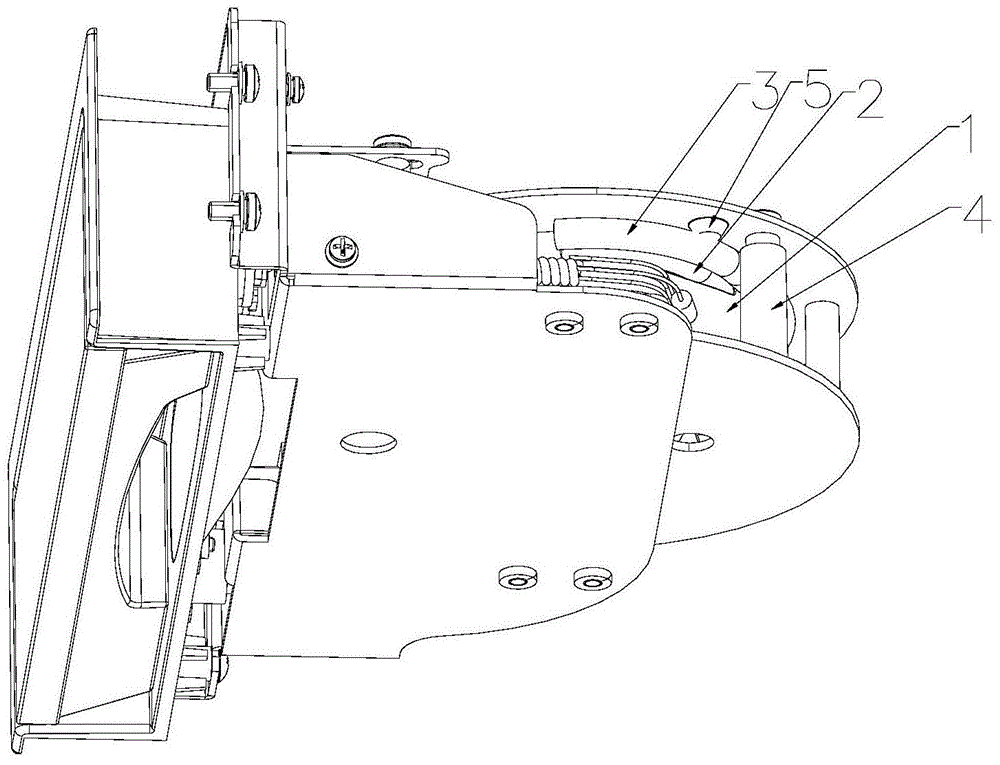

[0047] The present invention will be further described below in conjunction with accompanying drawing.

[0048] The existing take-up structure microphone wire winding is:

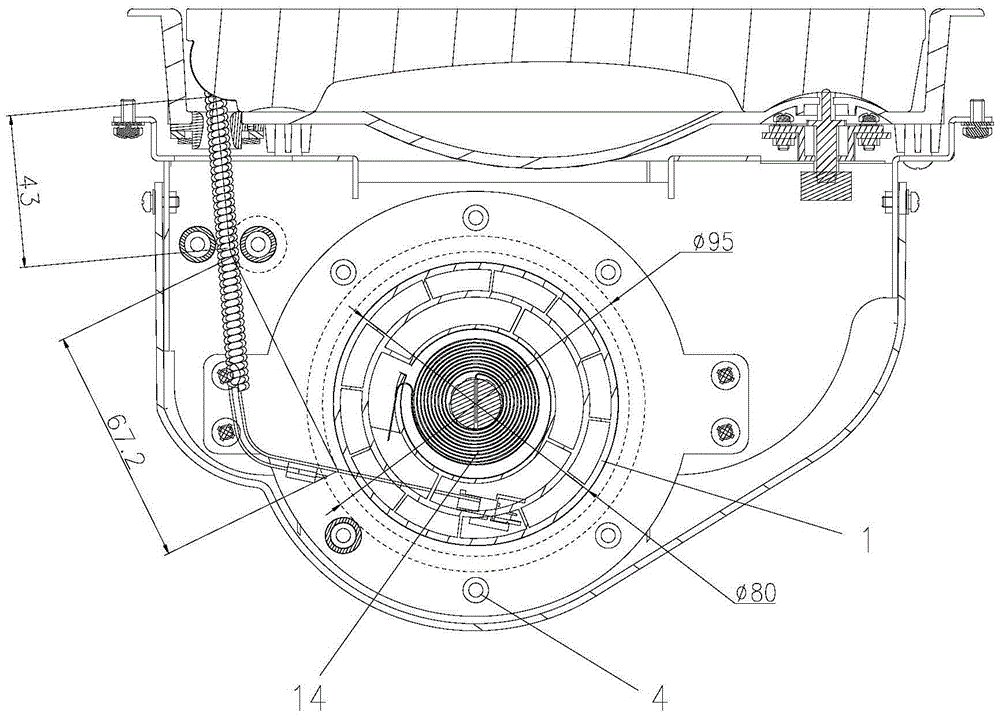

[0049] Figure 10 Shown: the microphone line of the telephone is connected to the outlet of the coil spring seat 1 through the coil spring seat upper cover 8 and the terminal on the internal conductive slip ring. And utilize the stainless steel pressing piece 12 to compress the connector on the coil spring seat 1.

[0050] This design has the following problems:

[0051] 1. The outlet position of the microphone line is at the upper position of the upper cover 8 of the coil spring seat, and the arrangement height of the microphone line is not enough, which may easily cause overlapping and staggering of the microphone line during the take-up process of the microphone line.

[0052]2. Since the coil spring seat 1 and the coil spring seat upper cover 8 are assembled, the height dimension is 28mm, the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com