A CNC tool

A technology of blade and cutter body, applied in the direction of tools for lathes, manufacturing tools, accessories of tool holders, etc., can solve the problems of insufficient clamping force, reduce tool life, affect tool life, etc. The effect of tool life, tool cost reduction, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

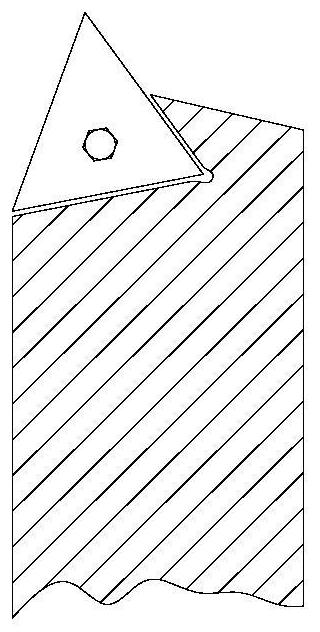

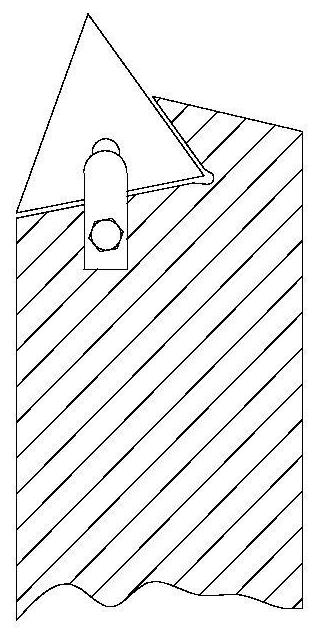

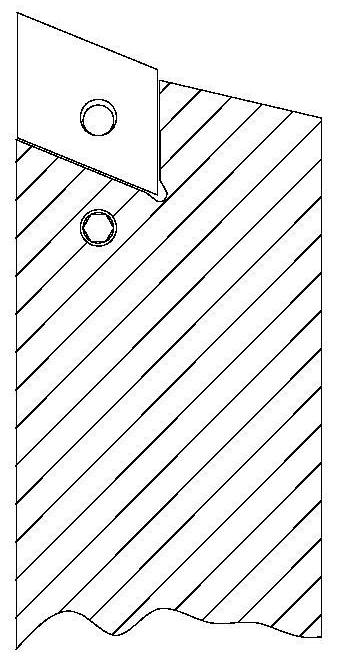

[0021] A kind of numerical control cutting tool of the present embodiment, such as figure 2 As shown, it includes a cutter body, a blade and a clamping part, and the clamping part includes a fixing nut, a pressing block for fixing the blade and a hook for fixing the blade; the front end of the cutter body is provided with The installation through hole is used for inserting the screw rod, the screw rod is provided with a V-shaped groove, the opening position of the V-shaped groove is matched with the hook head, the blade and the knife pad under the blade Pass through the hook head and lay flat in the knife groove of the cutter body. The pressing block is inserted into the upper end of the screw rod, and a fixing nut is arranged on the pressing block.

[0022] The bottom end of the screw rod is provided with a mounting hole, and the mounting hole is an inner hexagon.

[0023] The upper end of the screw is a flat structure.

[0024] The upper middle part of the screw rod has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com