Used sand regeneration mechanism

A technology of used sand regeneration and used sand, applied in the field of used sand regeneration mechanism, can solve the problems of increasing equipment cost, serious equipment wear, and fragile used sand particles, and achieves the goal of reducing replacement frequency, reducing requirements, and not easily broken. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

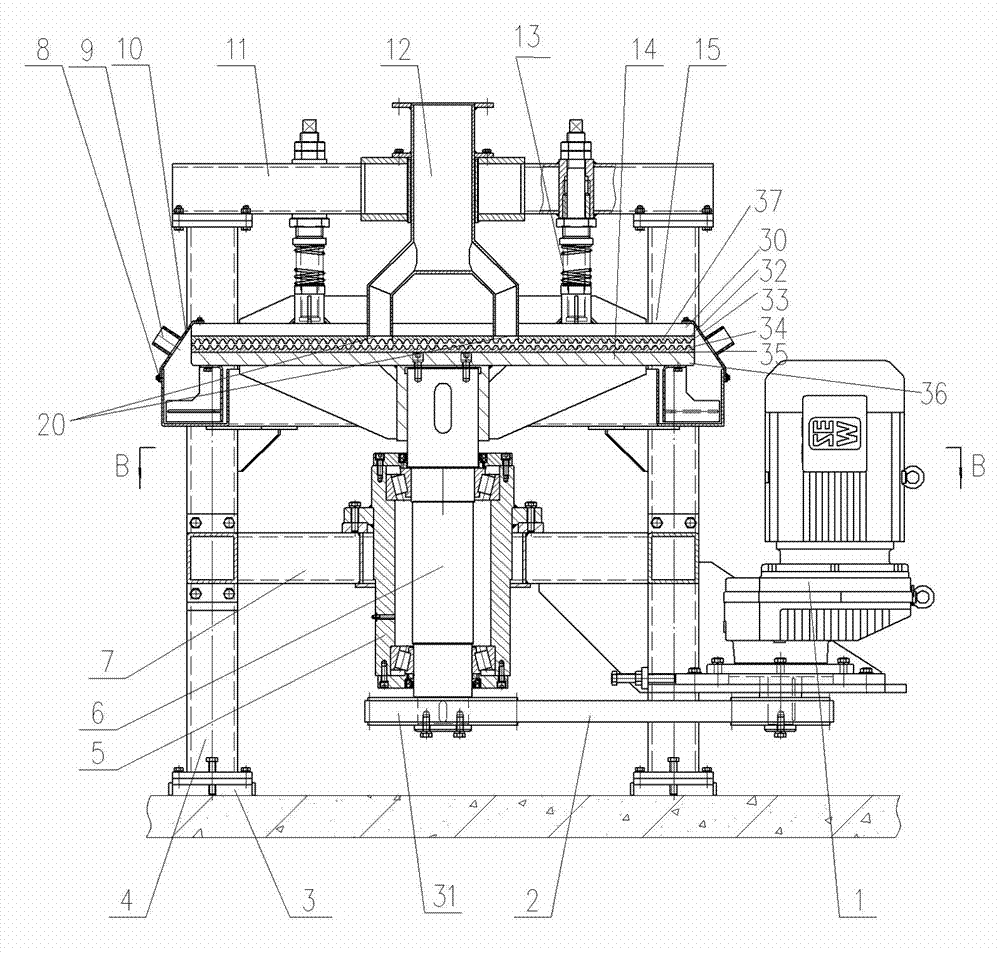

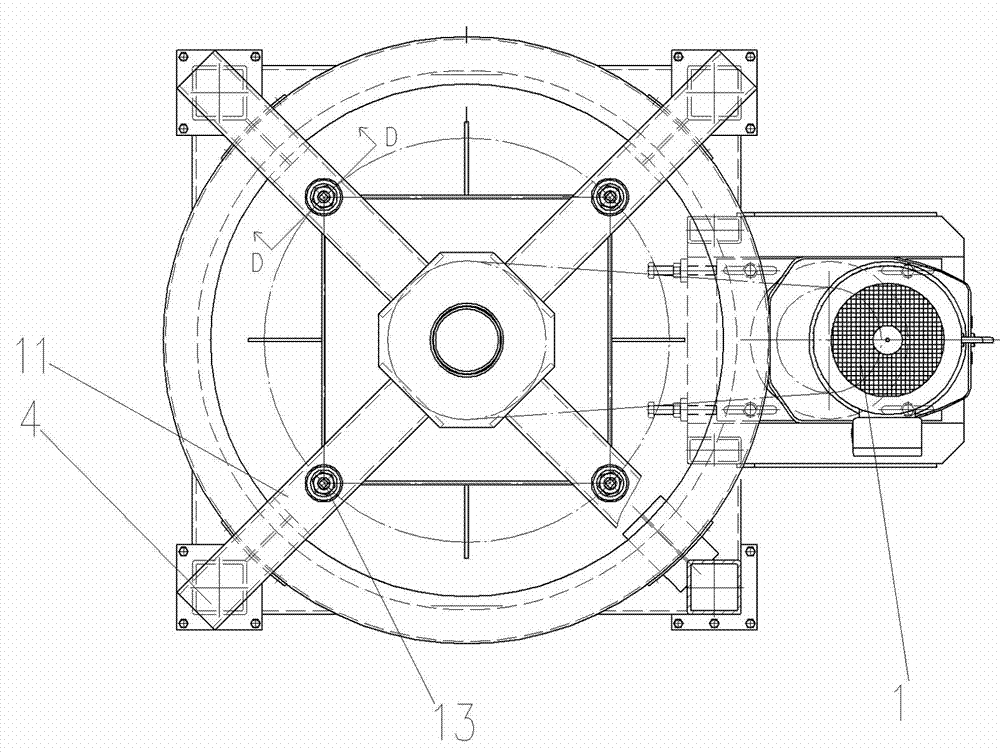

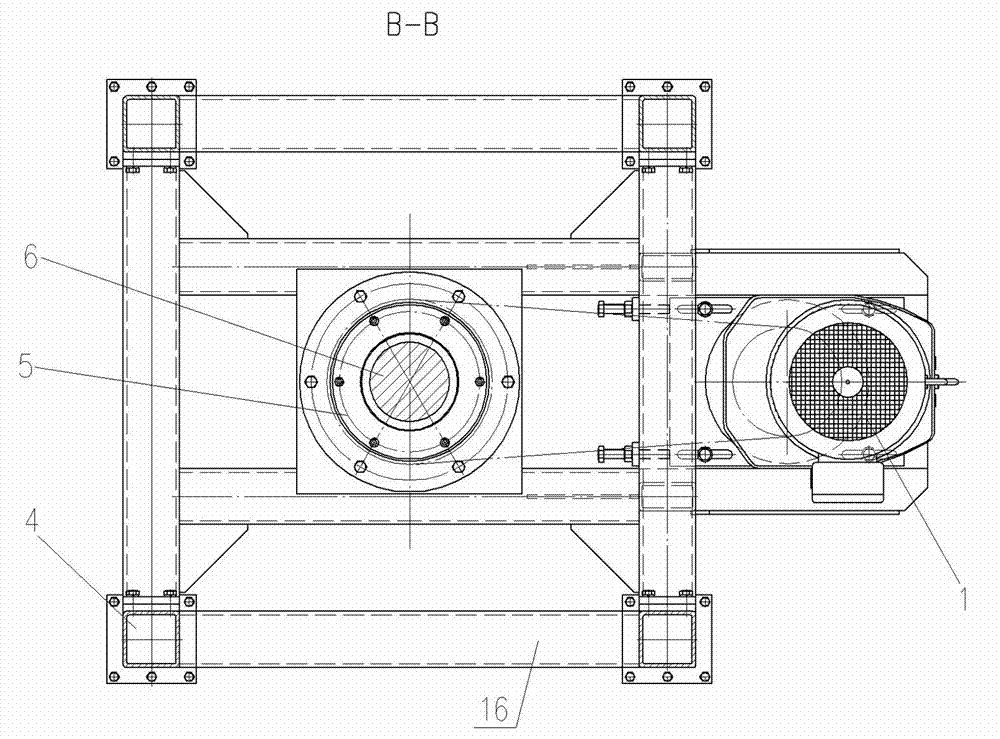

[0027] An example of an old sand regeneration mechanism Figure 1~8 As shown: it includes an upper grinding disc 15 and a lower grinding disc 14 which are arranged up and down oppositely. The lower grinding disc 14 can bear the loading force and rotate relative to the upper grinding disc 15, that is, the lower grinding disc 14 is provided with a torque input end for torque input. The upper millstone 15 includes an upper millstone body 30 and an upper millstone wear plate 32 made of wear-resistant alloy steel fixedly provided with the lower end of the upper millstone body 30. The upper millstone wear plate 32 consists of ten fan-shaped upper wear plates with the same shape. 17 are spliced together, and each fan-shaped upper wear-resistant plate 17 is fixedly connected with the upper grinding disc body 30 through the corresponding upper mounting structure. The upper positioning key 18 corresponding to the position of each upper positioning keyway on the body, the upper install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com