Electroplating head levelness detection device and method

A technology for level detection and electroplating head, applied in measuring devices, surveying and navigation, measuring inclination and other directions, can solve the problems of inability to guarantee the relative parallelism of electroplating heads, uneven flow field and electric field, defects in electroplating products, etc., to achieve accuracy High, convenient operation, simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

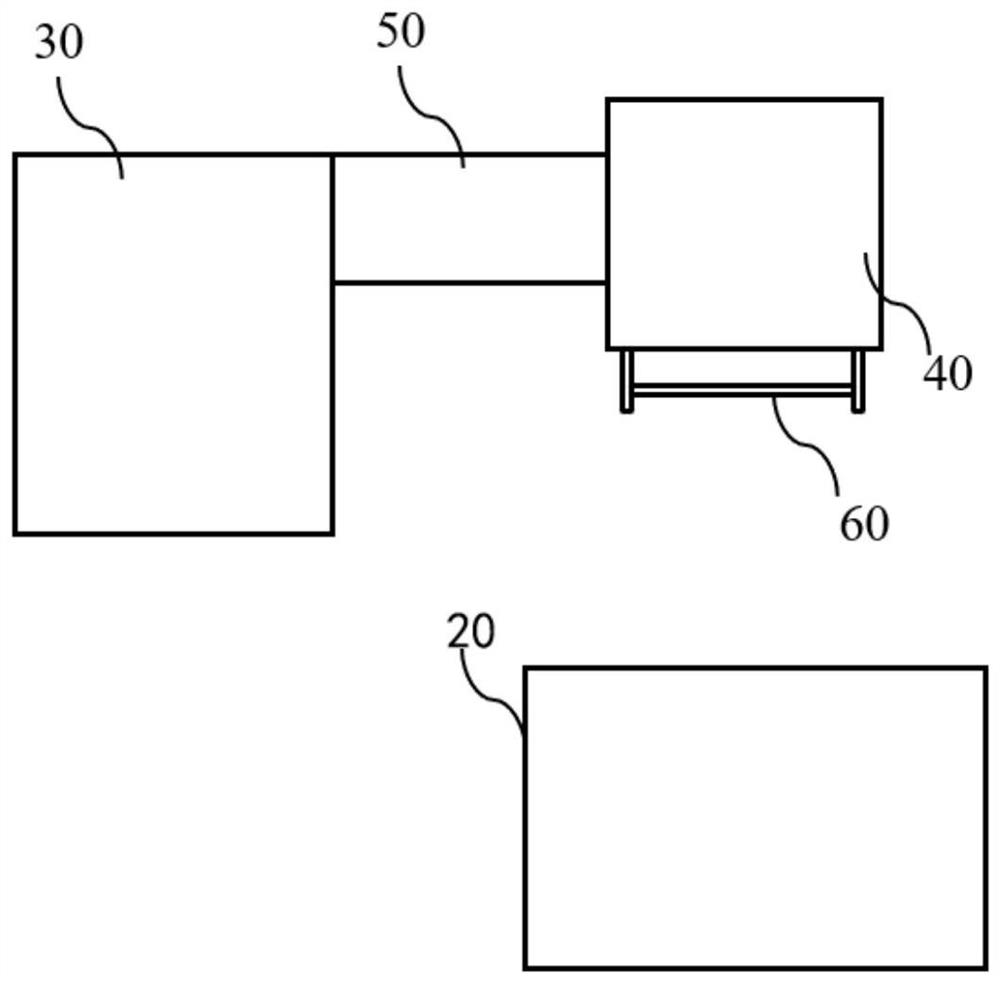

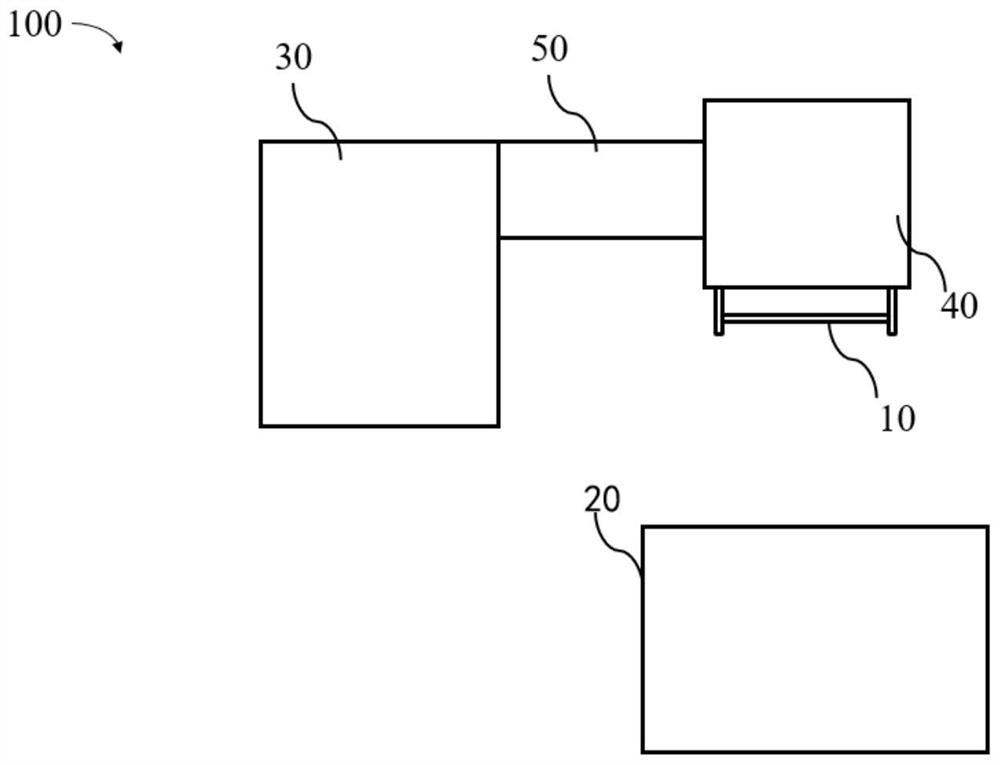

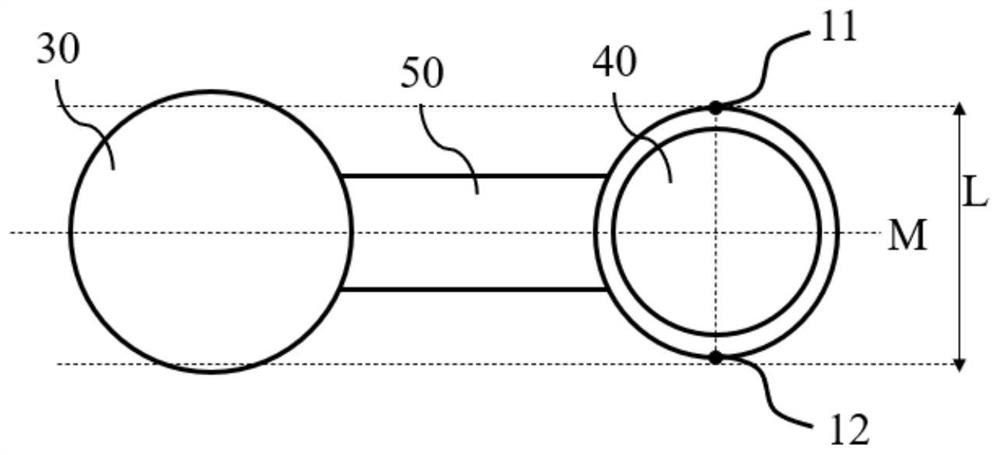

[0068] figure 1 A schematic structural diagram of an electroplating apparatus in the prior art is shown, which includes a driving device 30, an electroplating head 40 and an electroplating tank 20, wherein the driving device 30 is connected to the electroplating head 40, and the electroplating head 40 is provided with a wafer mounting surface, and the crystal The circle 60 is placed on the wafer mounting surface during electroplating, the electroplating tank 20 contains the electroplating solution, and the driving device 30 can drive the electroplating head 40 into the electroplating tank 20, so that the electroplating head 40 acts as the cathode of the electroplating tank 20, so that the The cations of the pre-plating metal in the plating solution adhere to the surface of the wafer 60 to form a plating layer. In addition, the electroplating equipment is also usually provided with a swing arm 50, which is connected to the electroplating head 40, and the swing arm 50 can drive ...

no. 2 Embodiment

[0082] This embodiment provides a method for detecting the level of an electroplating head, using the electroplating head level detecting device 100 described in Embodiment 1, such as Figure 5 shown, including the following steps:

[0083] installing the inspection tool 10 on the wafer mounting surface of the electroplating head 40;

[0084] make the driving device 30 drive the electroplating head 40 to enter the electroplating tank 20 at a preset speed;

[0085] The calculation unit detects the contact time between each contact and the electroplating solution, and calculates the contact time difference Δt;

[0086] The calculation unit determines whether the contact time difference Δt is less than or equal to a preset value.

[0087] Further, it also includes the following steps:

[0088] When the calculation unit judges that the contact time difference Δt is less than or equal to the preset value, the detection ends;

[0089] When the calculation unit determines that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com