Stacking device for intelligent warehouse goods shelf

A stacking device and shelf technology, applied in storage devices, vehicle energy storage, transportation and packaging, etc., can solve the problems of poor positioning of goods stacking, inability to achieve labor-saving stacking, and insufficient flexibility in overall use, and achieve rapid push and delivery Cargo device, easy to move equipment position, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

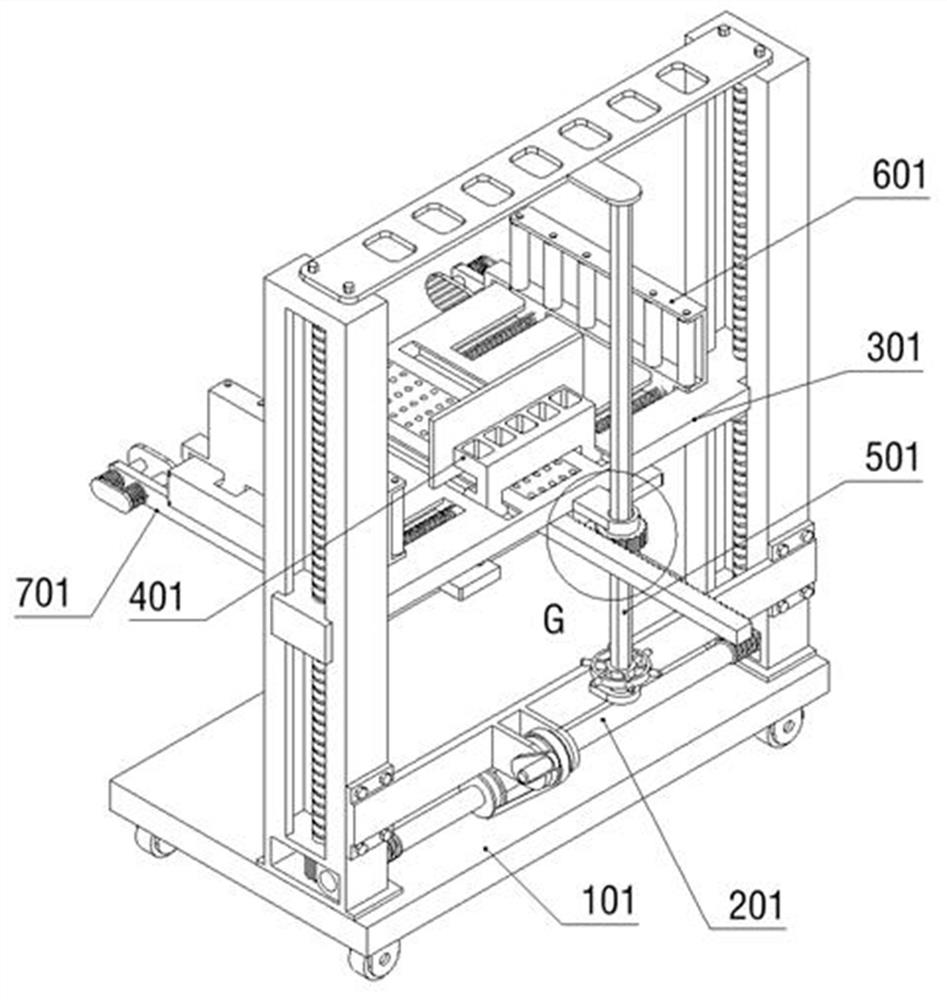

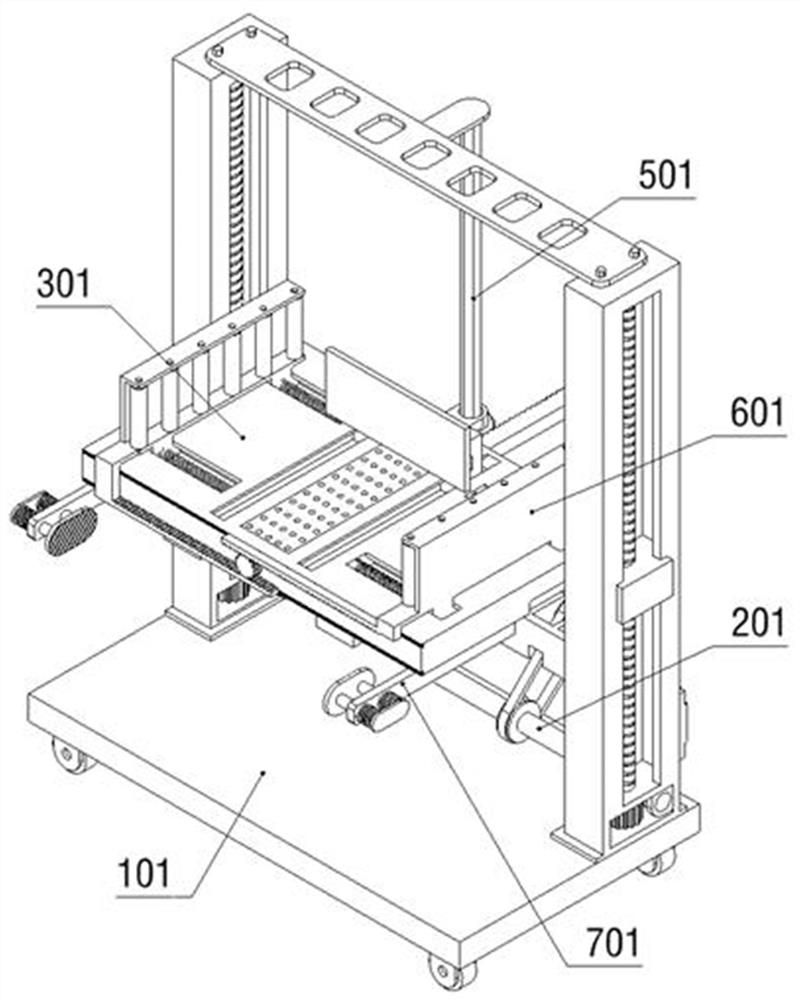

[0043] Please refer to Figure 1 to Figure 16 : The present invention proposes a stacking device for intelligent warehouse shelves, including a mobile support device 1; a drive device 2 is installed on the mobile support device 1; a delivery device 3 is installed on the mobile support device 1; the delivery device 3 A propulsion part 4 is slidably connected to the middle part; a propulsion drive device 5 is installed on the driving device 2; a positioning device 6 is installed on the delivery device 3; two anti-drop devices 7 are slidably connected at the bottom of the delivery device 3; The support base plate 101 is provided with rollers on four parts and four corners of the support base plate 101 respectively; the lifting installation block 102 is provided with two lifting installation blocks 102, and the two lifting installation blocks 102 are fixedly connected to the supporting base plate 101 respectively; the supporting screw rod 103, the supporting wire There are two rod...

Embodiment 2

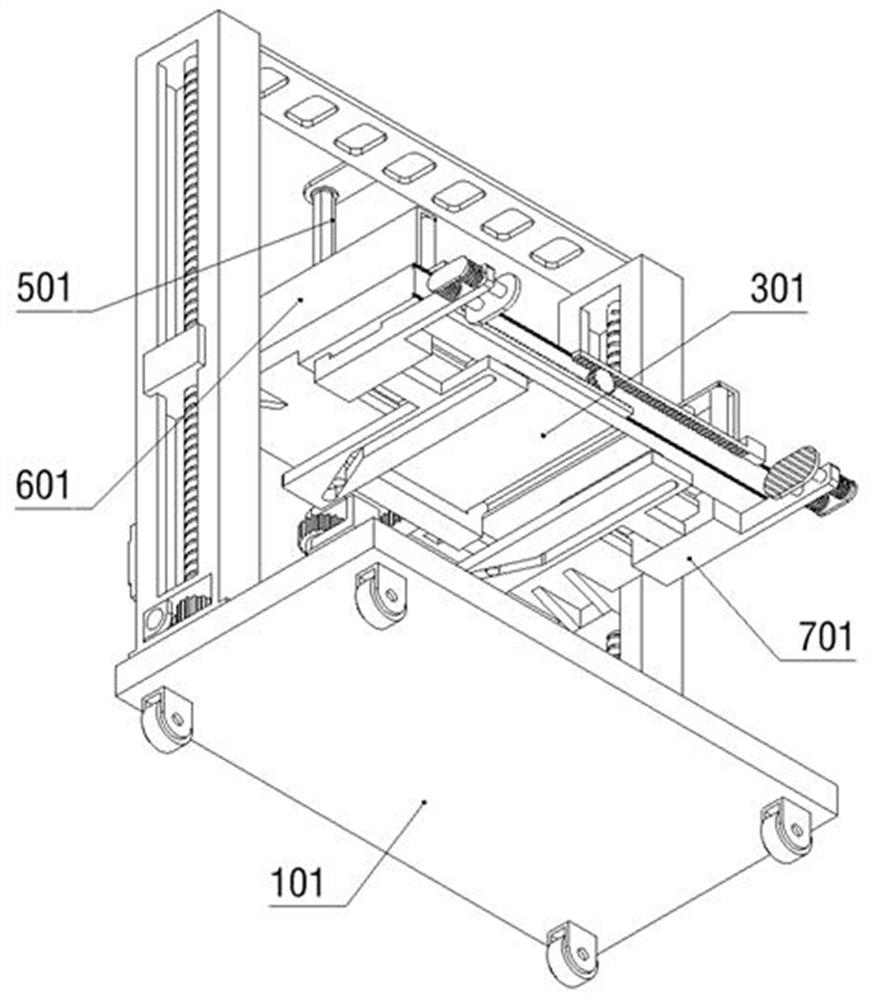

[0047] like Figure 13 , Figure 14 As shown, the positioning device 6 includes: positioning and advancing racks 601; two positioning and advancing racks 601 are provided, and the two positioning and advancing racks 601 are respectively slidably connected to the installation and delivery plates 301 on the delivery device 3; The rollers 602 are provided with two rows, and the two rows of protection rollers 602 are respectively connected to the two positioning push frames 601 in rotation; the opposite racks 603 are provided with two opposite racks 603, and the two opposite racks 603 are fixedly connected respectively. On the two positioning and propelling racks 601; the opposite meshing gear 604, the opposite meshing gear 604 is rotatably connected to the installation and delivery plate 301; the opposite meshing gear 604 is engaged with the two opposite racks 603; the driving tension spring 605, There are four driving tension springs 605, and the four driving tension springs 60...

Embodiment 3

[0049] like Figure 15 , Figure 16 As shown, the anti-drop device 7 includes: a polymerization sliding block 701, which is slidably connected to the bottom of the installation and delivery plate 301; a linkage plate 702, which is fixedly connected to the side of the polymerization sliding block 701; the linkage plate 702 is provided with The chute 7021; the front section of the chute 7021 is a straight slot, and the rear section is an oblique slot; the anti-drop device 7 further includes: a tightening axle frame 703, which is slidably connected to the polymerization sliding block 701; the tightening shaft Two tension springs are sheathed on the frame 703; the two tension springs are respectively fixedly connected between the tightening shaft frame 703 and the outer side of the linkage plate 702; the tightening shaft frame 703 passes through the polymerization sliding block 701; the anti-skid plate 704, the anti-skid plate 704 It is fixedly connected to the tightening axle fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com