Device for rolling bearing and method for producing same

A technology for rolling bearings and rolling elements, which is applied in the direction of rolling contact bearings, roller bearings, rotating bearings, etc., can solve the problems of shortened service life of bearings, and achieve the effects of reduced wear, good friction properties, and low friction coefficient values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

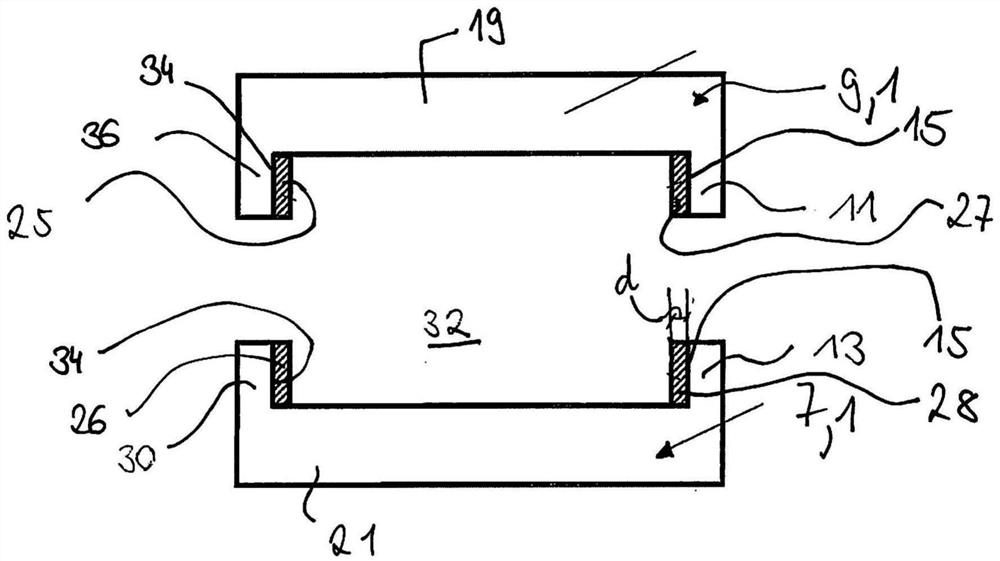

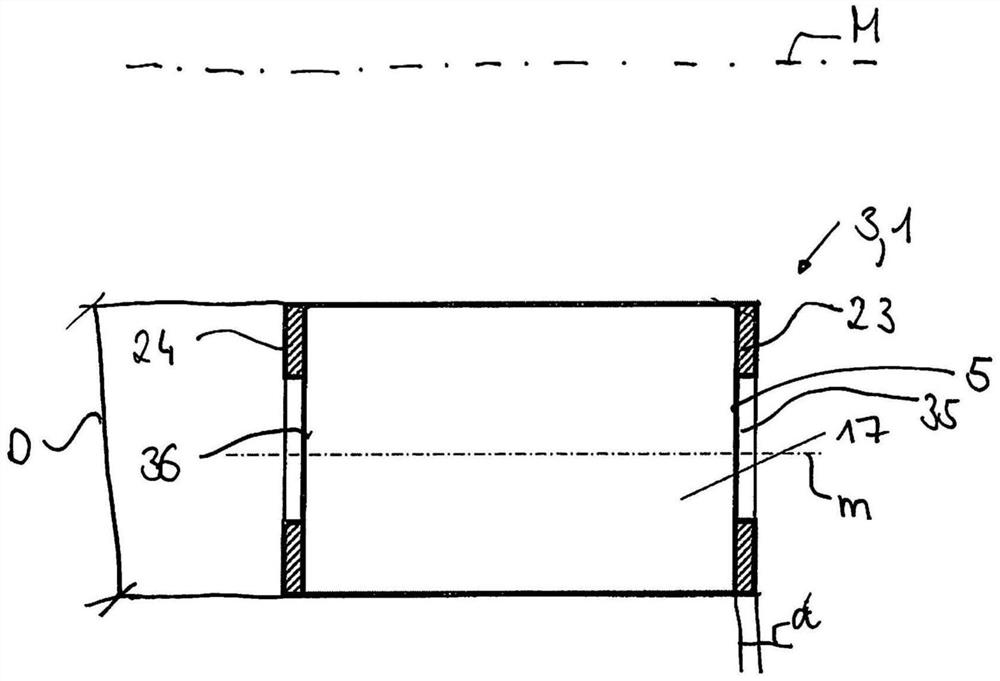

[0030] In the following description of the drawings, the same reference numbers refer to the same or similar parts. Furthermore, summarizing reference numerals are used for those parts and objects that appear multiple times in the embodiments or figures but are generally described with respect to one or more of their features. Components or objects denoted by the same or general reference numerals can be embodied identically with respect to individual, multiple or all technical characteristics, such as their dimensions, but can also be embodied differently, as long as there is no reference to the description Get different express or implied.

[0031] figure 1 A schematic diagram showing a cross-section of an outer ring and an inner ring as a device for a rolling bearing according to an embodiment of the present invention.

[0032] figure 1 A device 1 for rolling bearings is shown. The rolling bearing comprises at least one rolling element 3, for example in figure 2 shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com