Ink detection surface tension measuring device for digital printing

A technology of surface tension and digital printing, which is applied in the direction of surface tension analysis, etc., can solve the problems of inconvenient lifting speed, low degree of automation, poor stability, etc., to improve stability and uniform speed effect, and improve efficiency and convenience, improving the effect of fixed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

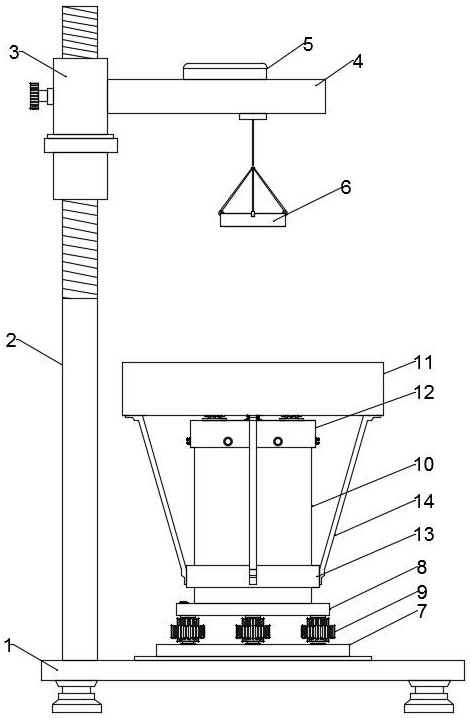

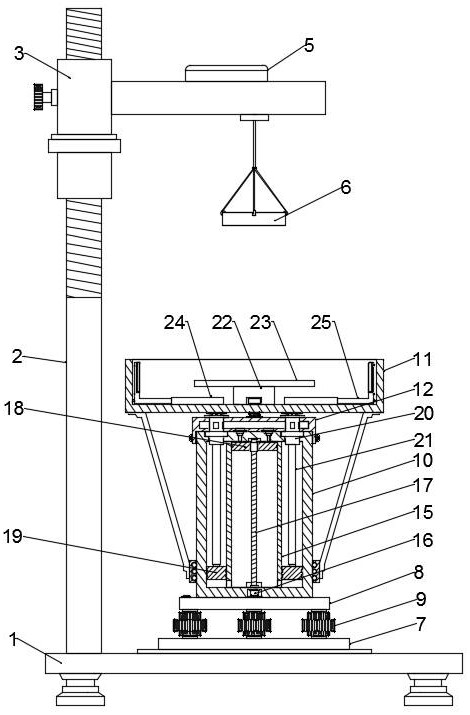

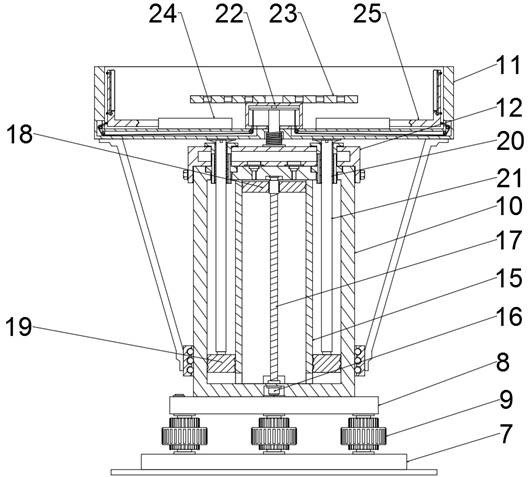

[0022] Example: see Figure 1-5 , a digital printing ink detection surface tension measuring device, comprising a base plate 1, a vertical rod 2 arranged on the top side of the base plate 1, an adjusting tube 3 arranged on the top of the vertical rod 2, and a beam 4 arranged on one side of the adjusting tube 3 And the silicon piezoresistive transmission sensor 5 located at the suspended end of the beam 4, a suspended detection ring 6 is installed on the detection end of the silicon piezoresistive transmission sensor 5, a base 7 is arranged on the middle part of the top surface of the bottom plate 1, and the base 7 There is a leveling seat 8 horizontally above the top surface, and a leveling tube is provided on the top side of the leveling seat 8 for horizontal calibration of the leveling seat 8. The leveling seat 8 and the base 7 are installed in a triangular shape. There are three foot screws 9; the top of the leveling seat 8 is vertically provided with a fixed cylinder 10, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com