Plastic and metal combined power supply module shell

A technology of power modules and plastic shells, applied in metal shells, electrical equipment shells/cabinets/drawers, metal containers, etc., can solve the problems of inability to interfere with shielding of electronic components, inability to dissipate heat, and shorten the service life of power modules, and achieve Good protection effect, good protection and service life, safety insulation metal heat dissipation and metal shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

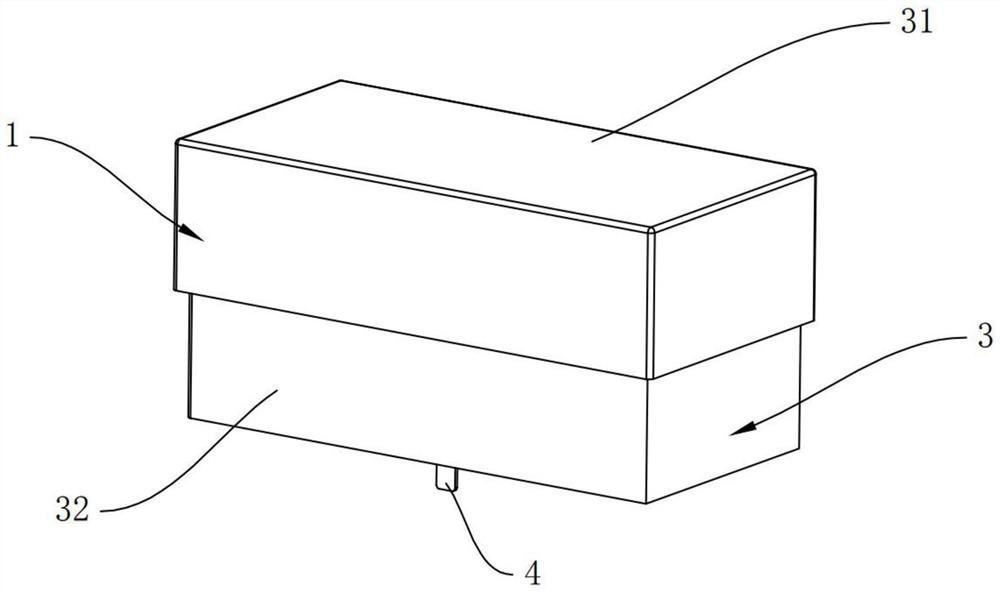

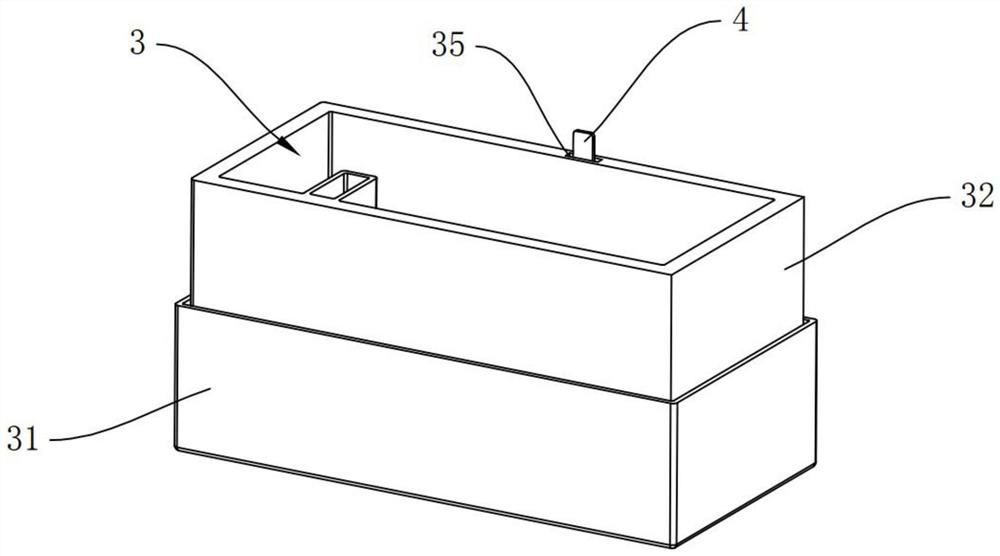

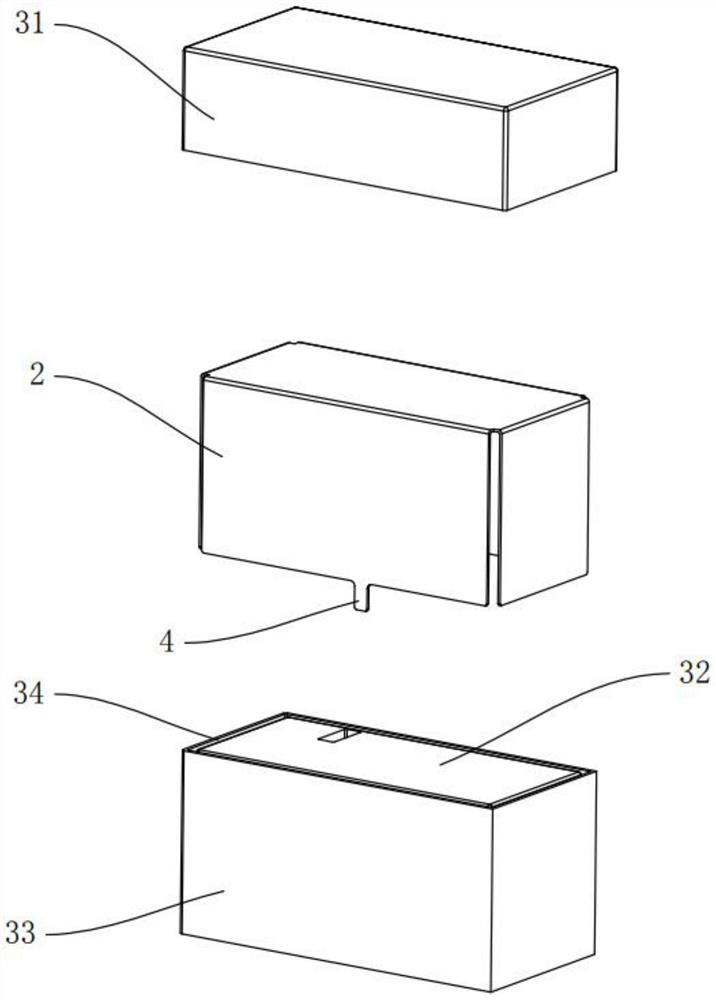

[0035] like Figure 1 to Figure 3 As shown, a plastic and metal combined power module housing includes a housing body 1. By fitting the housing body 1 to the power module, the protection of the power module is realized and the service life of the power module is prolonged; The housing body 1 in the example includes a metal housing 2 and a plastic housing 3. By enclosing the plastic housing 3 outside the metal housing 2, the housing body 1 can have the insulation safety distance characteristics of the plastic housing 3 and the metal housing at the same time. Due to the rapid heat dissipation characteristics of the metal casing 2, the power module can have an excellent protective effect after the housing body 1 of this embodiment is installed. Extend the service life of the power module.

[0036] like figure 2 As shown, the metal shell 2 of this embodiment is a box structure without a cover with an opening at the bottom, so that after the metal shell 2 is connected with the p...

Embodiment 2

[0040] like Figure 5 to Figure 6As shown, the difference from the first embodiment is that the plastic housing 3 of the second embodiment includes a plastic main body 32 and a semi-enclosed insulating barrier wall 36 surrounding the outer side of the plastic main body 32, wherein the bottom of the semi-enclosed insulating barrier wall 36 is connected to the The bottom of the plastic main body 32 is connected to form an integrated structure, and the semi-enclosed insulating retaining wall 36 is combined with the outer side wall of the plastic main body 32 to form an installation interlayer 34 that is semi-enclosed on one side of the plastic main body 32. By inserting the metal shell 2 into the installation interlayer The assembly of the metal shell 2 and the plastic shell 3 is realized in 34; in this embodiment, a semi-enclosed insulating retaining wall 36 is arranged outside the plastic shell 3, which simplifies the production process and production cost compared with the firs...

Embodiment 3

[0042] like Figure 7 As shown in the figure, the difference from the first and second embodiments is that the plastic shell 3 and the metal shell 2 of the third embodiment are integrally formed. The body 1 reduces the subsequent assembly process of the shell body 1, and the metal shell 2 is surrounded by the plastic shell 3 as a whole, so that the shell body 1 has the characteristics of metal heat dissipation while ensuring safety and insulation; this embodiment The connecting pins 4 pass through the plastic shell 3 and extend to the bottom of the metal shell 2 , so that the connecting pins 4 can be welded or riveted to the circuit board, thereby realizing the metal shielding function of the shell body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com