Cutting device for door and window aluminum profiles

A cutting device and aluminum profile technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., to achieve the effect of improving cutting efficiency, stable swing, and convenient operation

Active Publication Date: 2022-06-10

四川精诚致远门窗工程有限公司

View PDF20 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the deficiencies of the prior art, the present invention provides a cutting device for aluminum profiles for doors and windows, which can compress and loosen the aluminum profiles to be cut before and after cutting, which is convenient Assembly line operation, which solves the problems of uneven incision and low cutting efficiency of aluminum profiles caused by the existing hand-held cutting operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

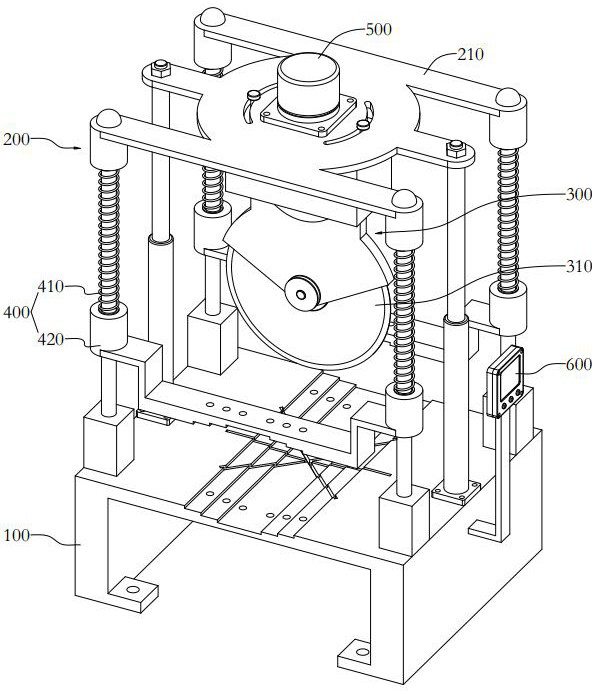

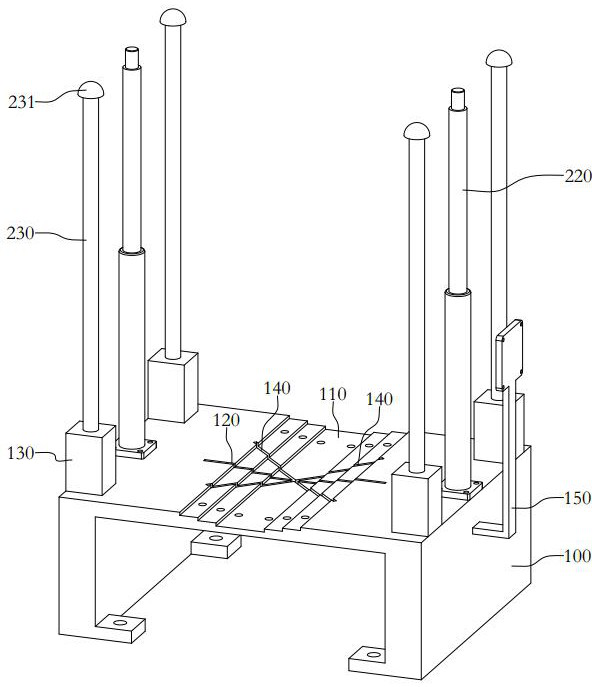

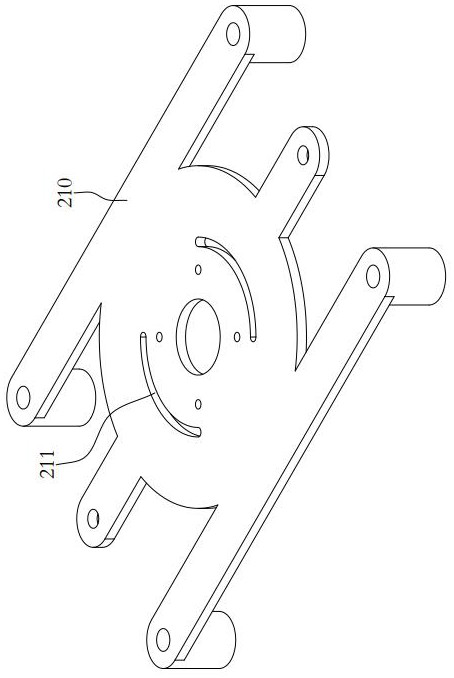

The invention belongs to the technical field of cutting equipment, and provides a door and window aluminum profile cutting device which comprises a base, a lifting mechanism, a saw cutting mechanism and a pressing mechanism, the top face of the base is provided with a containing groove with the same width as the aluminum profile and a first cutting seam perpendicularly intersecting with the containing groove, and the lifting mechanism is connected to the upper portion of the base and provided with a lifting table; the saw cutting mechanism is connected with the lifting table and provided with a saw blade right opposite to the first cutting seam, and the pressing mechanisms are symmetrically arranged on the two sides of the saw blade. The pressing mechanism comprises a spring and a pressing plate, one end of the spring is connected with the lifting table, and the other end of the spring is connected with the pressing plate. The pressing plate is located above the containing groove and below the saw blade. The arranged pressing mechanism and the saw cutting mechanism act synchronously through the lifting mechanism, aluminum profiles to be cut can be pressed and loosened before and after cutting, assembly line work is facilitated, and the cutting efficiency is improved; and during cutting, the aluminum profile is pressed into the containing groove through the reset force of the spring, and the stability in the cutting process is improved.

Description

technical field [0001] The invention belongs to the technical field of cutting equipment, and in particular relates to a cutting device for aluminum profiles of doors and windows. Background technique [0002] Aluminum profiles are aluminum materials with different cross-sectional shapes obtained by hot-melting and extruding aluminum rods. In recent years, China's aluminum processing industry has closely combined the needs of the market and scientific development, making traditional aluminum profiles gradually complete the transition to modern aluminum profiles. Therefore, the variety of Chinese aluminum profiles has undergone tremendous changes. The important characteristics of Chinese aluminum profiles are Develop in the direction of high performance, high precision, energy saving and environmental protection. [0003] At present, the extruded aluminum profiles are usually in the shape of long strips, and the aluminum profiles are usually cut to facilitate assembly and us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23D45/00B23D47/00

CPCB23D45/00B23D47/00

Inventor 黎千军袁书波赵忠阳王兰琼

Owner 四川精诚致远门窗工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com