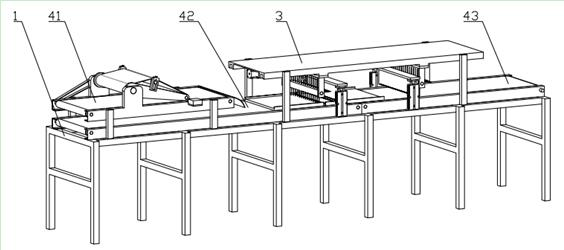

Slicing and shredding integrated equipment for undaria pinnatifida stems

A technology of undaria stalks and slices, which is applied in metal processing and other directions, to achieve the effect of simple adjustment, lower enterprise costs, and lower labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

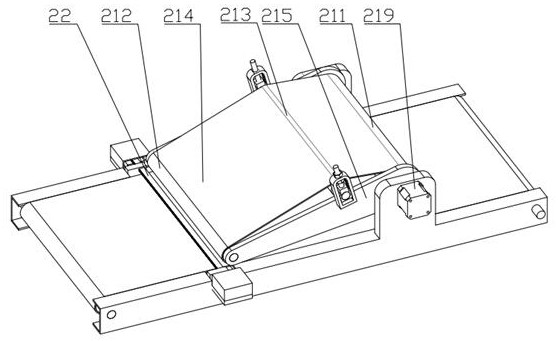

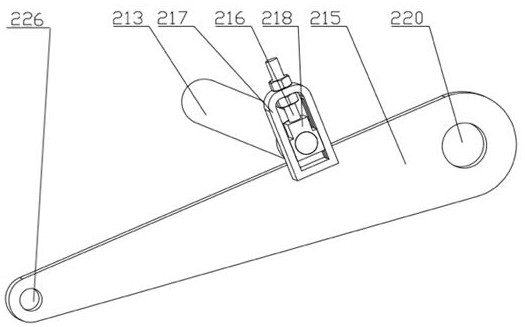

Embodiment Construction

[0026] When the first pressing groove 311 overlapped with the pressing plate 37, the belt conveyor II 42 stopped conveying, the cylinder 36 was connected with the pressing plate 37, and the cylinder 36 drove the pressing plate 37 to move downward to compress the tray 31 and the wakame stalk, The motor drives the wire-cutting tool 34 to rotate, and the wire-cutting tool 34 rotates to the second half of the wakame stalk from the non-needle row surface under the action of the motor, and the second half of the wakame stalk is scratched. Under the action of the motor, it rotates to the needle-free surface and returns to the initial position. By analogy, the wire-scribing tool 34 is rotated to the middle-pitch needle row surface and the small-pitch needle row surface in turn to perform the second and third times of wire-scribing. Plate 37 moves upwards, and tray 31 continues to be transported forward by belt conveyor III43. When the second pressure groove 312 coincided with the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com