Aerated plate wet-state vertical breaking-off system and breaking-off method

A sheet, wet technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., to achieve the effect of improving efficiency, reducing power drive burden, and solving damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

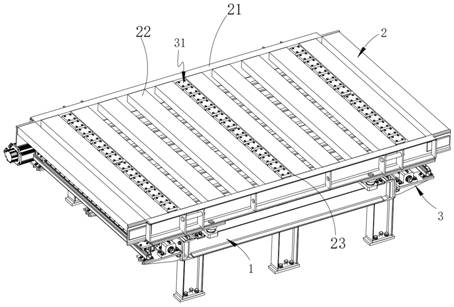

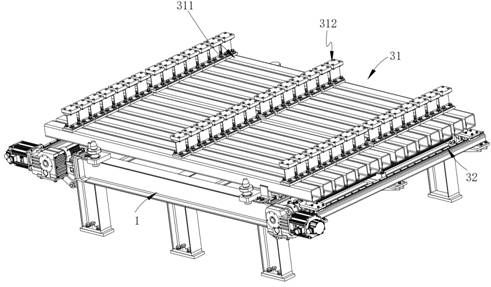

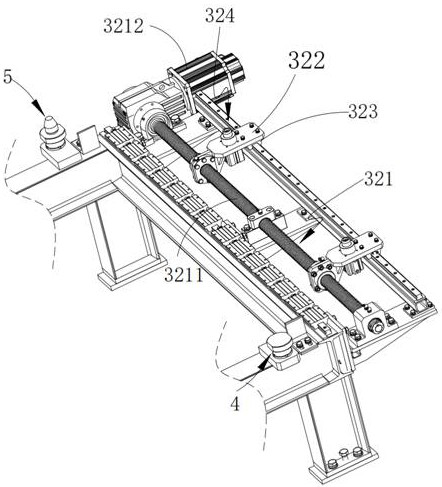

[0046] like figure 1 and 6 As shown, the carrying unit 2 includes:

[0047] In this embodiment, by using the integrated structure formed by the side beams 21 and the longitudinal beams 22, the stability of the structure during the steam curing process is ensured, and in the distribution of the longitudinal beams 22, by connecting adjacent longitudinal beams 22 A guide space 23 is formed between them, so that when splitting the AAC products on the steam-cured floor, the two-way splitting of the concrete slabs is carried out on both sides along the sliding direction of the guide space 23 by using a splitting machine, and through this guide space 23. It can also ensure the discharge of condensed water during the steam-curing process of AAC products, and through the moving block assembly 312 arranged in the guide space 23 on both sides of the side beam 21 in the length direction, the steam-cured bottom plate can be positioned and placed through the positioning space 23 When brea...

Embodiment 2

Embodiment 3

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap