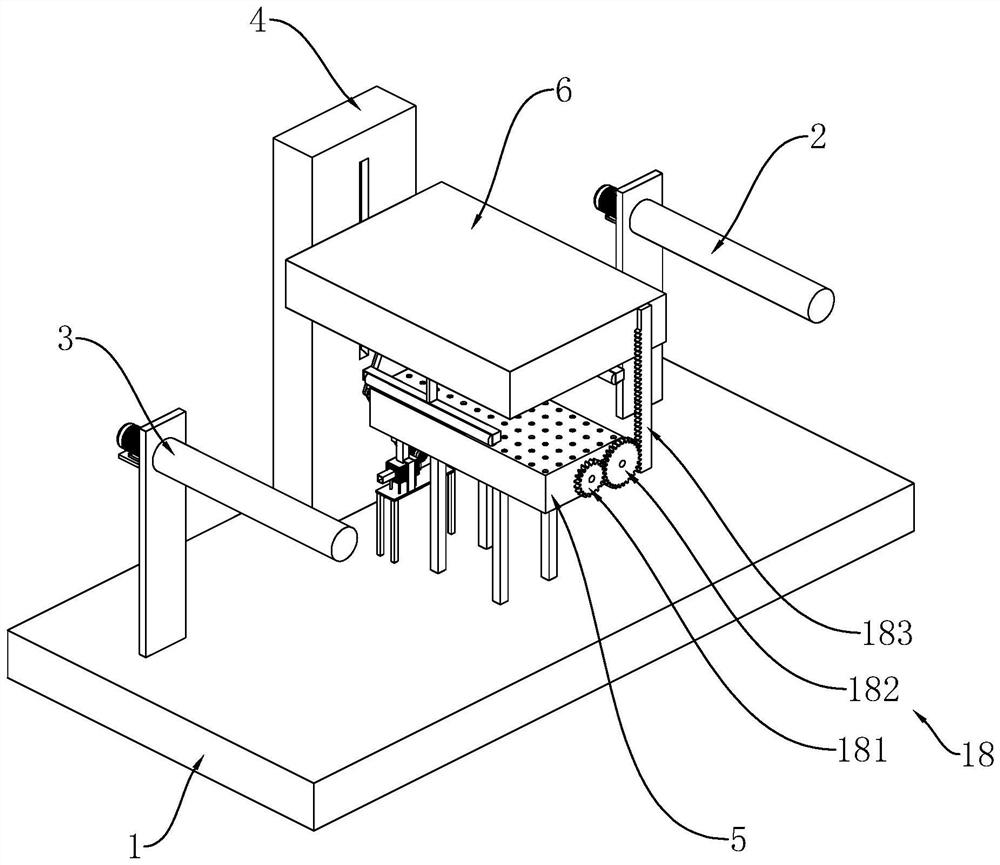

Cloth printing equipment

A printing equipment and fabric technology, applied in printing, printing presses, rotary printing presses, etc., to improve production efficiency and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

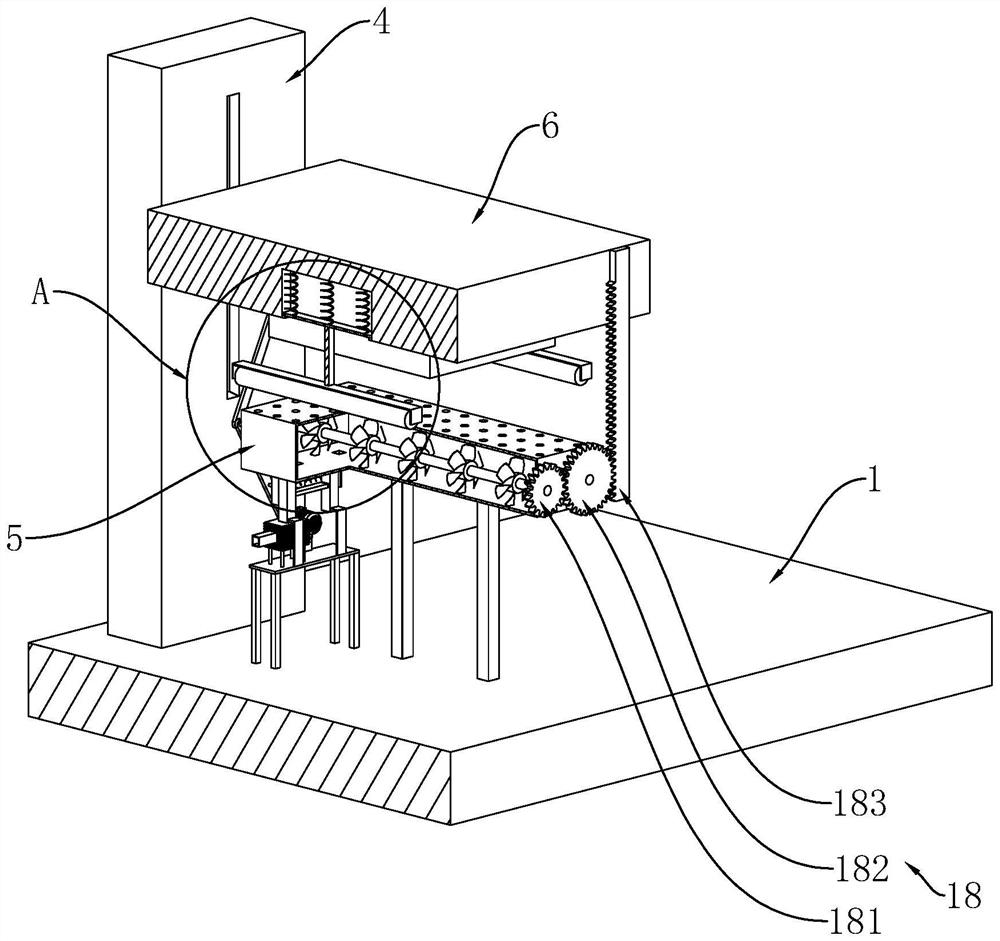

[0020] refer to image 3 and Figure 4 One end of the mounting shaft 15 extends to the outside of the receiving block 5, the control mechanism 18 includes a driven gear 181 fixed to the end of the mounting shaft 15 outside the receiving block 5, and the side wall of the receiving block 5 is rotatably connected with a transmission gear 182. The transmission gear 182 meshes with the driven gear 181 , so that the transmission gear 182 can drive the driven gear 181 to drive the installation shaft 15 to rotate. At the same time, the number of teeth of the driven gear 181 is less than that of the transmission gear 182, which reduces the transmission ratio, so that the installation shaft 15 can rotate more times.

[0021] refer to image 3 and Figure 4 , the lower end of the support block 6 is vertically fixedly connected with a driving rack 183 , and the driving rack 183 is meshed with the transmission gear 182 . When the supporting block 6 moves downward, the driving rack 183 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com