Method for preventing pulverized coal sedimentation in shaft during drainage and mining of coal-bed gas well

A technology for coalbed methane wells and coalbed methane, which is applied in mining equipment, gas discharge, earth-moving drilling, etc., to achieve the effects of positive production drainage, preventing settlement and accumulation, and reducing the number of workover operations.

Pending Publication Date: 2022-06-10

PINGDINGSHAN TIANAN COAL MINING +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the pulverized coal fishing operation adopts the method of killing or venting the well. The well killing will cause water to flow into the coal seam, which may block the passage. Moreover, the pulverized coal fishing operation needs to lift the drainage equipment out of the well bottom, which affects the normal drainage and production.

A three-vehicle movable well cleaning device is adopted. To clean a well, a total of three vehicles, including a sewage treatment device truck, a well cleaning pump truck, and a water tank truck, are required to work together. It is inconvenient to use and operate, and the construction cost is relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

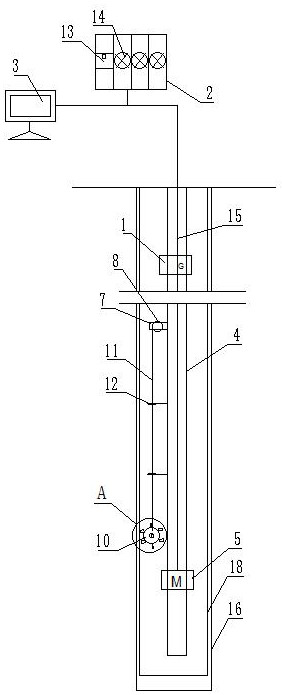

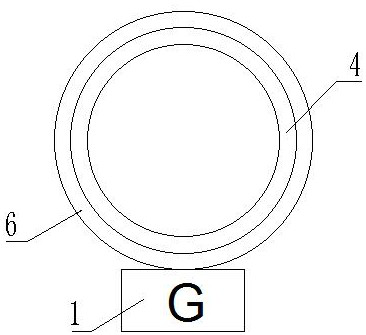

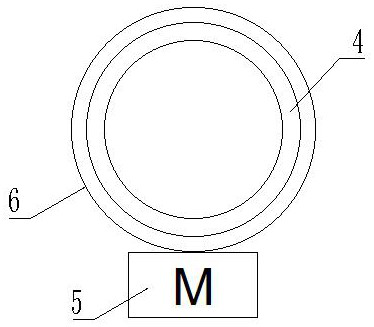

A shaft pulverized coal sedimentation prevention method during coal-bed gas well drainage and mining specifically comprises the following steps that firstly, a coal-bed gas drainage pulverized coal sedimentation prevention device is assembled, and the coal-bed gas drainage pulverized coal sedimentation prevention device comprises a pulverized coal monitoring system, a pulverized coal disturbance system, a signal transmitter, an alarm and a computer remote control system; (2) the pulverized coal monitoring system and the pulverized coal disturbance system are put into a target position in a shaft along with the oil rod; (3) inputting a pulverized coal concentration critical value and a disturbance instruction into the computer remote control system; (4) a pump is started to conduct normal coal bed gas drainage and mining, the pulverized coal monitoring system monitors the concentration of pulverized coal in the shaft in real time, and the pulverized coal disturbance system is controlled to conduct disturbance operation in the shaft; and (5) after the pulverized coal concentration returns to normal, the pulverized coal monitoring system enters a normal monitoring state. The concentration of pulverized coal in the shaft can be monitored in real time, disturbance operation can be conducted on the pulverized coal, the pulverized coal is prevented from settling and gathering in the shaft, the number of times of well repair operation is reduced, and normal production drainage and mining of a coal-bed gas well are achieved.

Description

technical field [0001] The invention relates to the technical field of coalbed methane exploitation, in particular to a method for preventing coal powder settlement in a wellbore during coalbed methane well drainage. Background technique [0002] Coalbed methane is mainly stored in coal reservoirs in the state of adsorption. When developing coalbed methane on the ground, it is necessary to drain the water in the coalbed through the wellbore to reduce the pressure of the reservoir, so that the coalbed methane can be desorbed and produced. The coal itself has the characteristics of low elastic modulus, after the reservoir is fracturing, the coal seam is further broken. During drainage, the pulverized coal will gradually move to the wellbore. When the drainage intensity is low, it is not enough to carry the pulverized coal out of the wellbore. The pulverized coal will accumulate in a certain part of the wellbore, and the output of pulverized coal will reduce the pump efficiency...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21F7/00E21F17/18

CPCE21F7/00E21F17/18

Inventor 李延河王保玉李喜员倪小明焦继红熊志文符辉高迪王英伟赵锦程仝艳军李刚赵菲

Owner PINGDINGSHAN TIANAN COAL MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com