Method for using all-steel climbing frame

A climbing frame and safety technology, which is applied in the field of building climbing frames, can solve the problems of all-steel climbing frames such as safety hazards, inability to overhaul, and impact on service life, and achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016]下面将结合本发明实施例中,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。

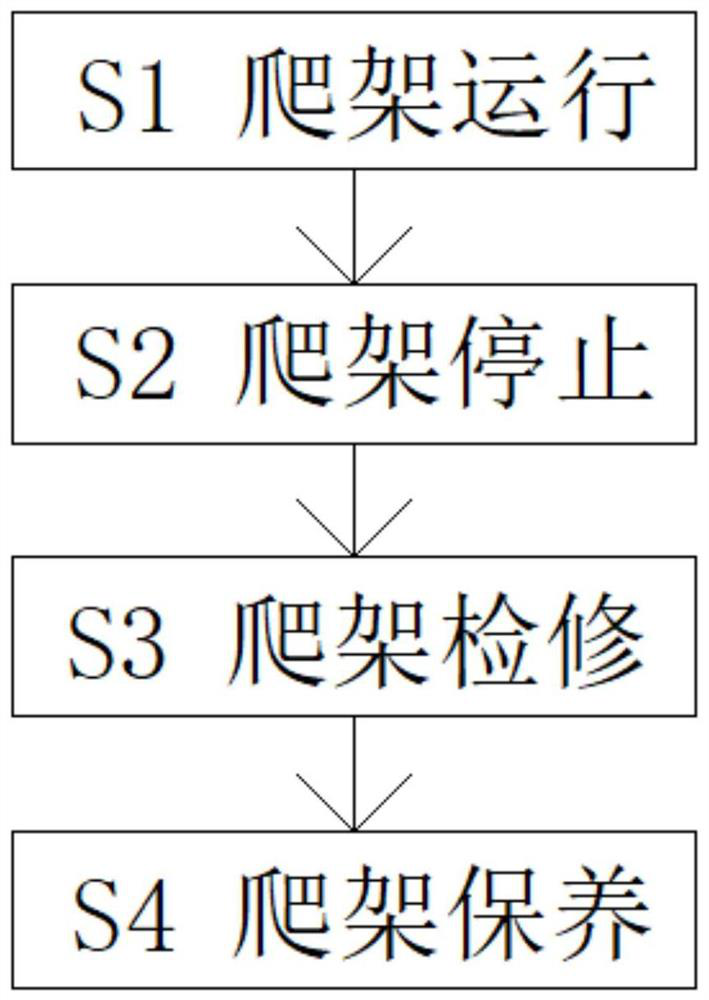

[0017]本发明提供一种技术方案:一种全钢爬架使用的方法,使用方法包括如下:

[0018]S1,爬架运行:首先启动电动葫芦,由电动葫芦带动全钢爬架进行提升,当爬架提升了一定高度后停止提升,然后由工作人员对全钢爬架进行检查,当确认全钢爬架安全无误后,接着继续让全钢爬架进行升降,同时在持续爬升的过程中当由专门的监控人员巡视爬架的升降情况,一旦发现异常应及时吹口哨向控制人员报警,避免爬架继续运行发生安全隐患;

[0019]S2,爬架停止:当全钢爬架提升或者下降到固定位置后,即可将外部的翻板放下来,以防止混凝土的进入,然后安装好限位锁,且需要在限位锁与导轮组之间用木方加木楔楔实;

[0020]S3,爬架检修:在全钢爬架使用的过程中为了确保能够安全顺利的运行,所以需要对各个结构组件进行定期检修,首先针对所有的螺栓连接件进行检查,需要检修的结构包括螺栓连接件、升降动力设备、防倾倒防坠装置和电控设备;

[0021]S4,爬架保养:首先取出黄油,并将黄油涂抹在穿墙丝杆上,然后清除导轮组及提升底座上的混凝土等杂物,保证导轮组及提升底座能够顺利运行,其次在电动葫芦表面利用帆布或者塑料布包封,最后提升钢丝绳的外部涂抹机油,防止出现生锈的情况。

[0022]步骤S1中,爬架运行:首先启动电动葫芦,由电动葫芦带动全钢爬架进行提升,当爬架提升50mm后,停止提升,然后由工作人员对全钢爬架进行检查,当确认全钢爬架安全无误后,即可将限位锁和最下一个导向件拆除并将其放置好,接着继续让全钢爬架进行升降,同时在持续爬升的过程中当由专门的监控人员巡视爬架的升降情况,一旦发现异常应及时吹口哨向控制人员报警,避免爬架继续运行发生安全隐患。

[0023]步骤S2中,爬架停止:当全钢爬架提升或者下降到固定位置后,即可将外部的翻板放下来,并将其固定好使用防护结构将提升底座防护好,以防止混凝土的进入,然后安装好限位锁,且需要在限位锁与导轮组之间用木方加木楔楔实,同时木方垫高不能大于150mm。

[0024]步骤S3中,爬架检修:在全钢爬架使用的过程中为了确保能够...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com