Verification method for non-power-cut replacement feasibility of spacer layer device of intelligent substation

A technology of smart substation and verification method, which is applied in the field of verification of the feasibility of replacement of the interval layer device of the smart substation without power failure, and can solve problems such as the inability to achieve unified replacement, unified debugging, and the fact that the device does not dare to move or cannot be replaced, and achieves The effect of solving the difficulty of replacing power outages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Describe the technical scheme of the present invention in detail below in conjunction with accompanying drawing:

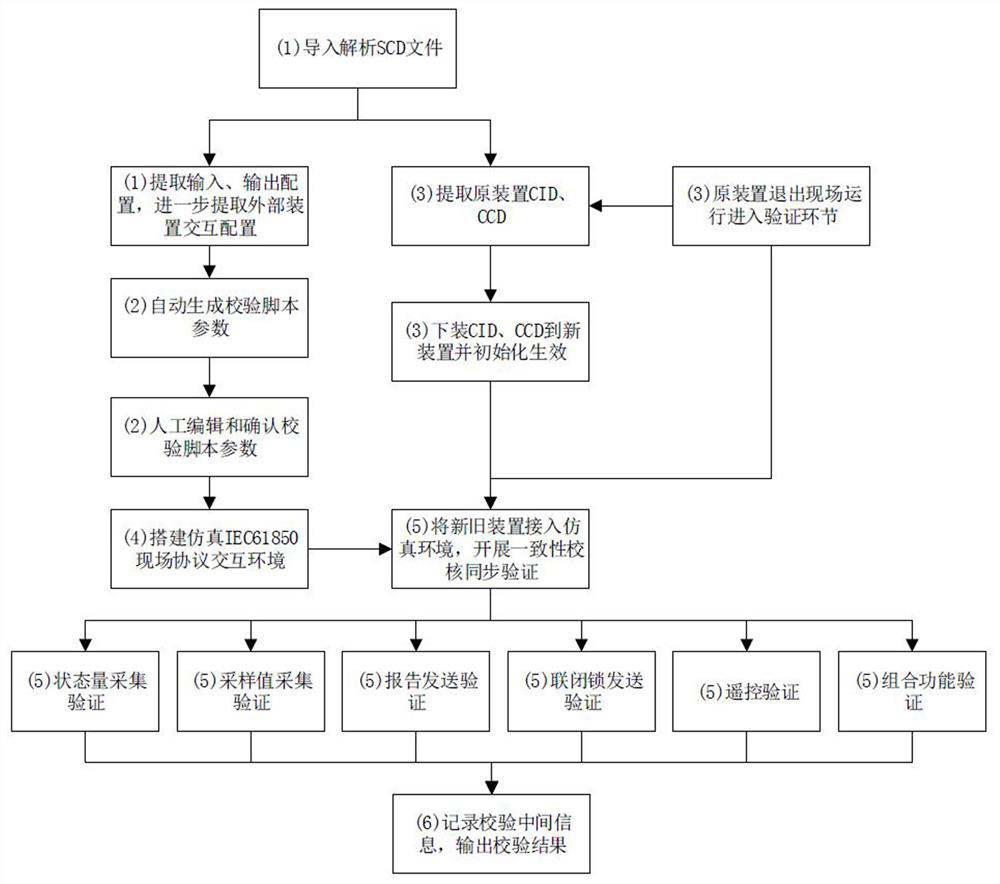

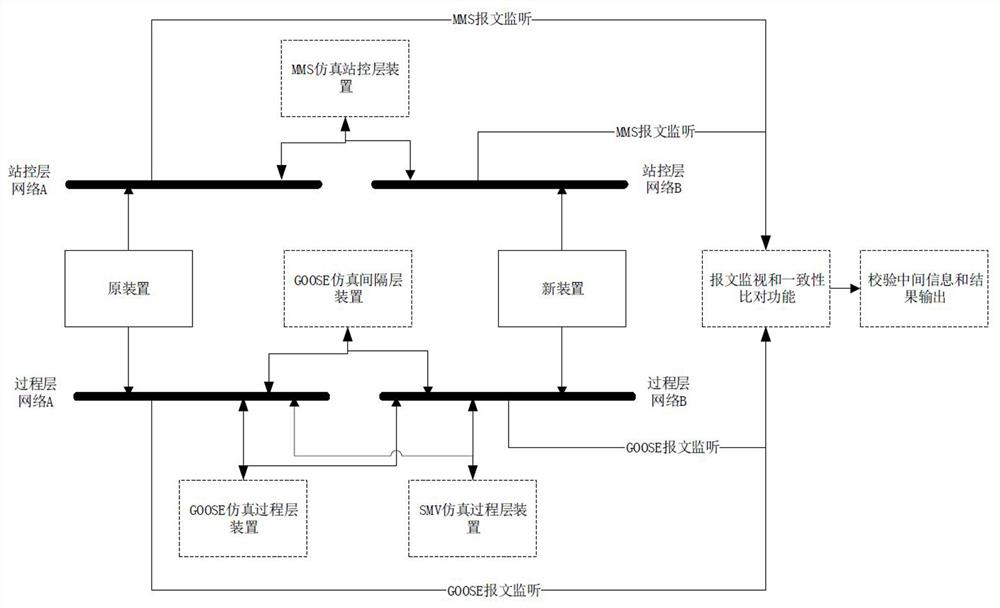

[0035] like figure 1 A method for verifying the feasibility of non-power-off replacement of a bay layer device in an intelligent substation, comprising the following steps:

[0036] S1: Use the smart substation SCD file to obtain the original device input configuration, output configuration and external device interaction configuration.

[0037] Preferably, the SCD file is obtained from the on-site user of the smart substation and imported for analysis, and the name of the IED (such as C_L2201A) corresponding to the specified original device is selected in the SCD, and the following configuration parameters are extracted with the IED as the center:

[0038] Extract the configuration parameters of the IED itself: traverse all the data set (DataSet) configuration parameters in the IED, get all the externally sent information point parameters as the original ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com