Tool for grouting groove on pile side of steel pipe pile

A steel pipe pile and grout groove technology, which is applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of inability to meet the rotation requirements of steel pipe piles, easy collision and damage to the pipe body of steel pipe piles and roller equipment, etc. Avoid slippage, ensure smooth rotation and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment, the technical scheme of the present invention is further described:

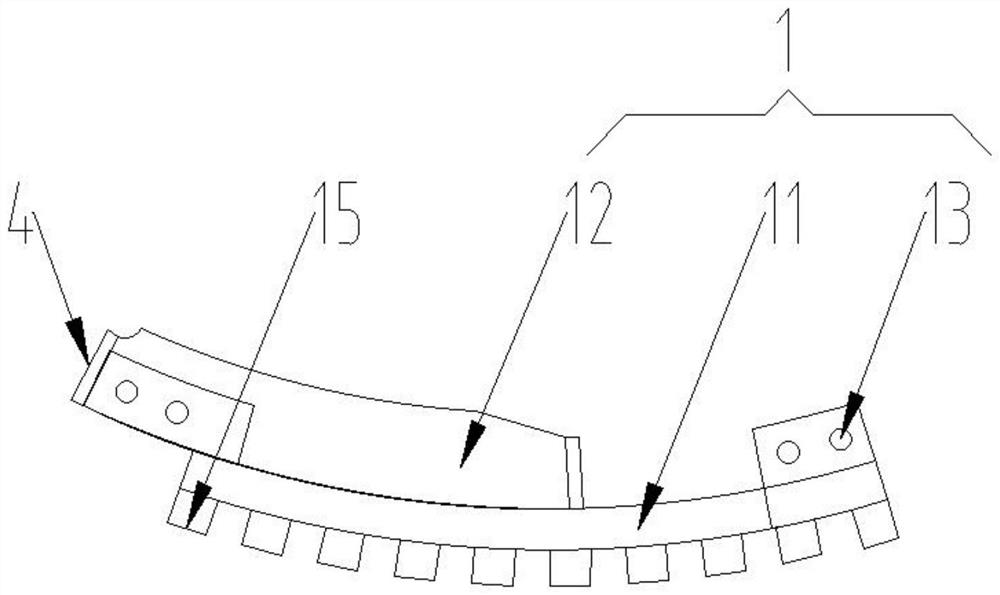

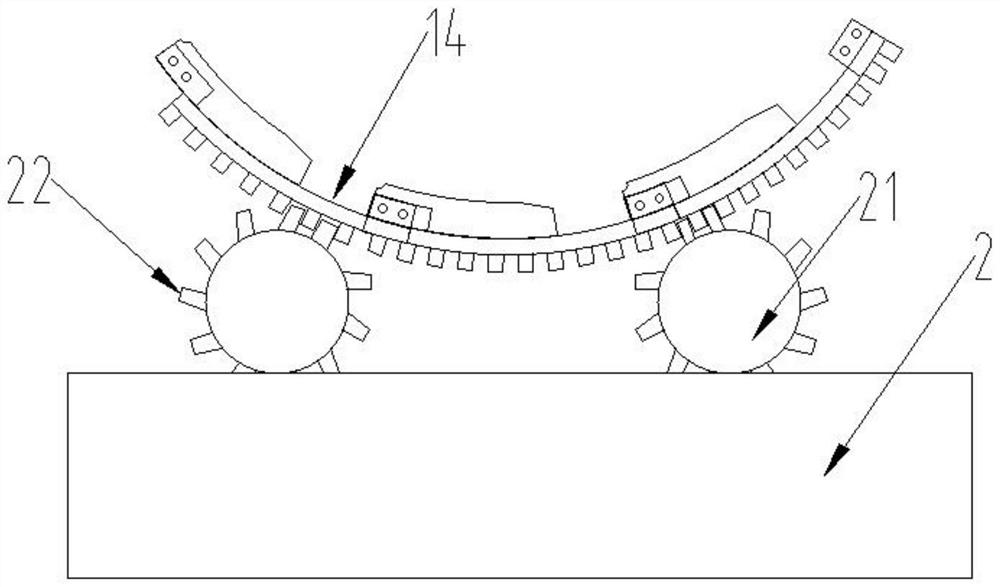

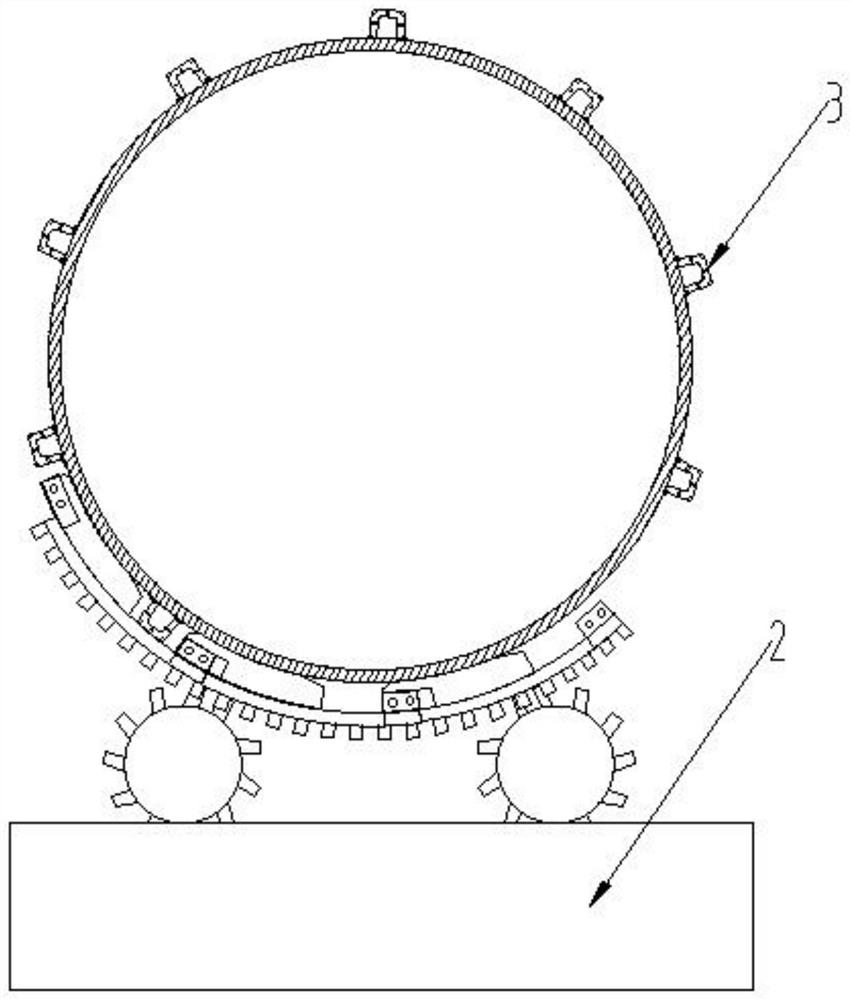

[0024] refer to Figure 1-4 As shown, the present invention provides a tool for a grouting groove on the side of a steel pipe pile, which includes at least three groups of pressure-bearing mechanisms 1, and multiple groups of the pressure-bearing mechanisms 1 are connected end-to-end by bolts, and the pressure-bearing mechanisms 1 It includes: a base plate base 11, one end of the base plate base 11 is provided with a number of special-shaped rib plates 12, the other end is provided with a connecting plate 13 corresponding to the number of the special-shaped rib plates 12, the top of the special-shaped rib plate 12 is provided on both sides with installation Slot 5 , a hydraulic buffer mechanism 6 is embedded in the installation slot 5 , and a roller frame 2 is arranged under the pressure bearing mechanism 1 .

[0025] As a preferred embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com