Torsional vibration reduction device

A torsional vibration and torque technology, which is applied in the direction of rotation vibration suppression, vibration suppression adjustment, shock absorber, etc., can solve the problems of vibration reduction characteristics and vibration reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described. In addition, the embodiment described below is merely an example of the present invention and does not limit the present invention, and the torsional vibration reducing device of the present invention can be appropriately modified or replaced as necessary to implement the embodiment described below.

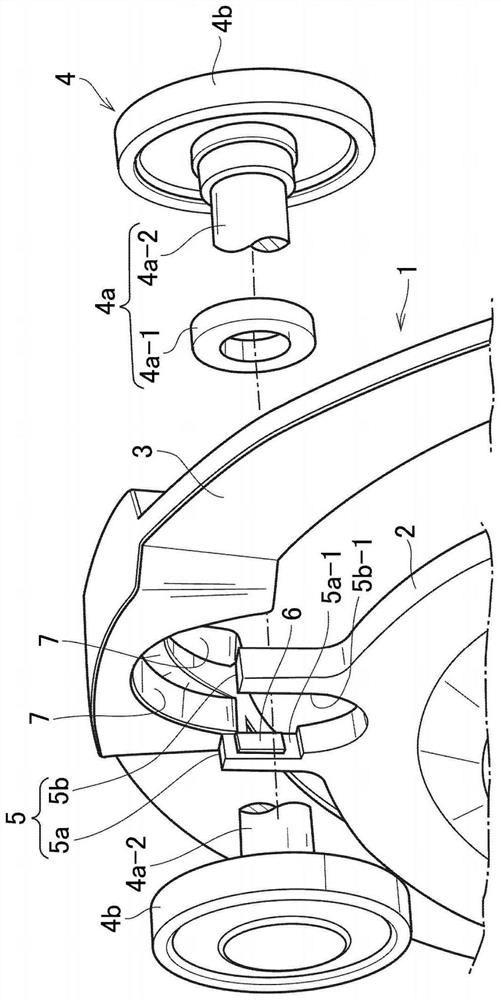

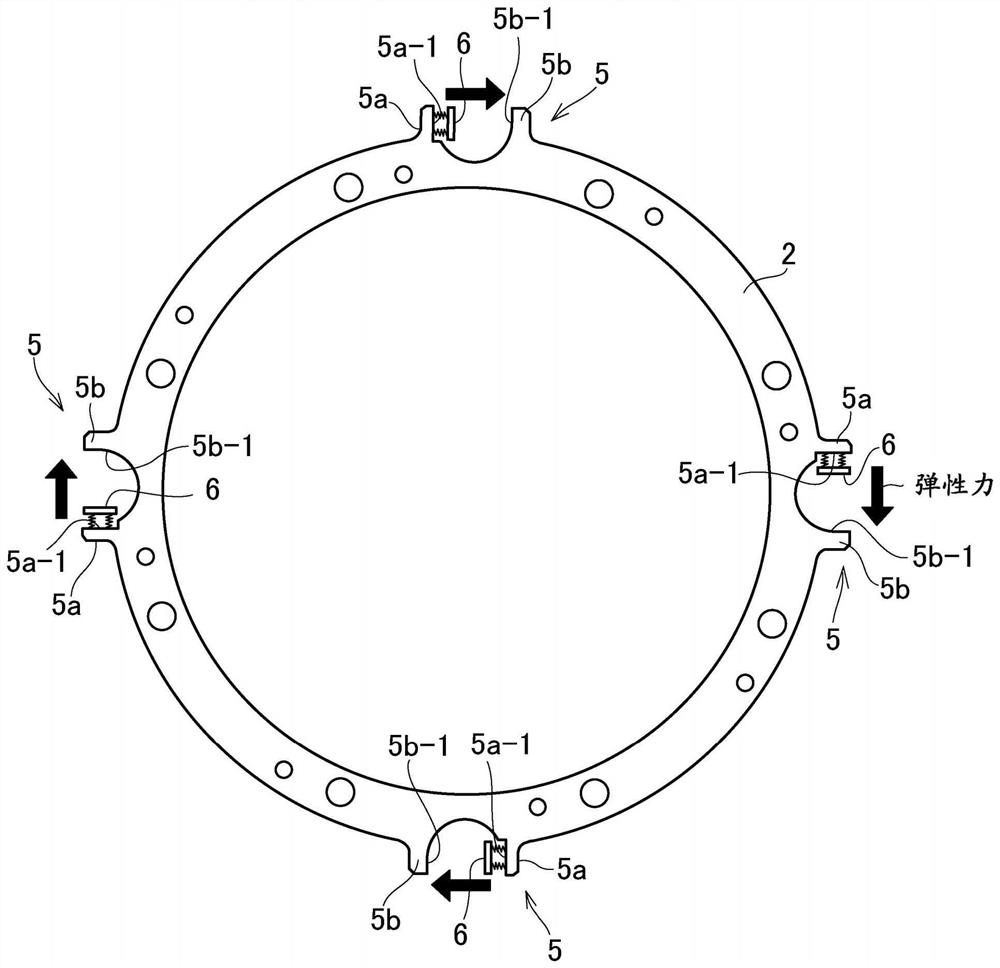

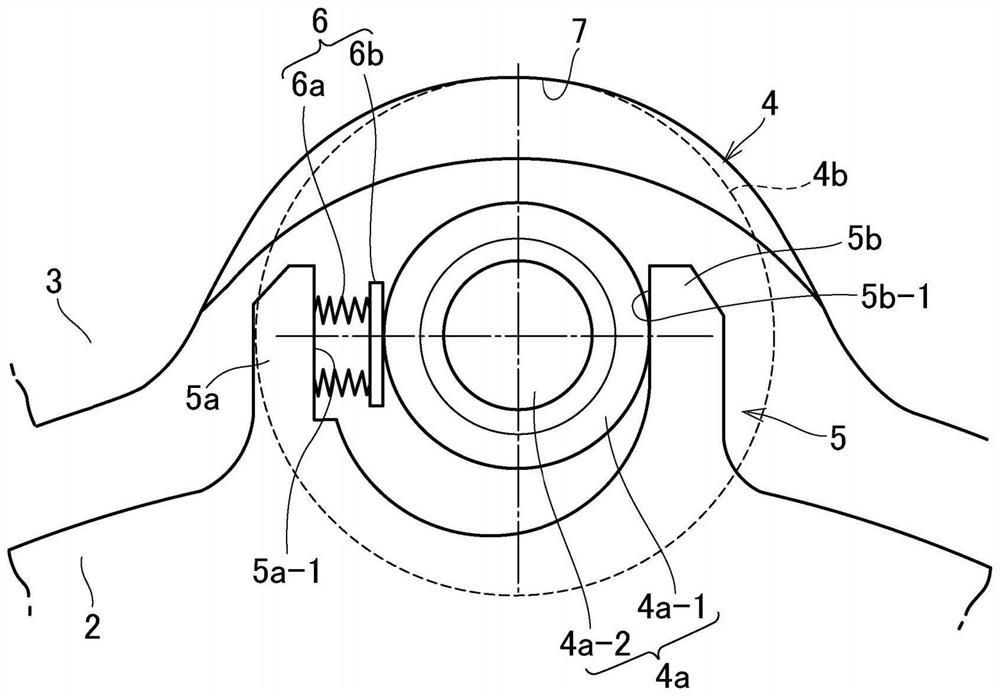

[0033] figure 1 It is a partial view for explaining the outline of the structure of the torsional vibration reduction device which is the object or the premise of the present invention, and shows the main structural members in an exploded manner. The torsional vibration reduction device 1 shown here connects the inertial mass body 3 functioning as a vibrator in a relatively rotational manner, in other words, in an oscillating manner, via a centrifugal weight 4 to input torque that inevitably generates vibrations The inertial mass body 3 swings (vibrates) with a lag relative to the rotating body 2 , where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com