Automobile covering part shaping die for teaching

A technology of automobile cover parts and shaping punches, which is applied in the field of teaching automobile cover part plastic molds, which can solve the problems that teachers are difficult to explain and students are difficult to understand, and achieve the effects of improving teaching effect, small size and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

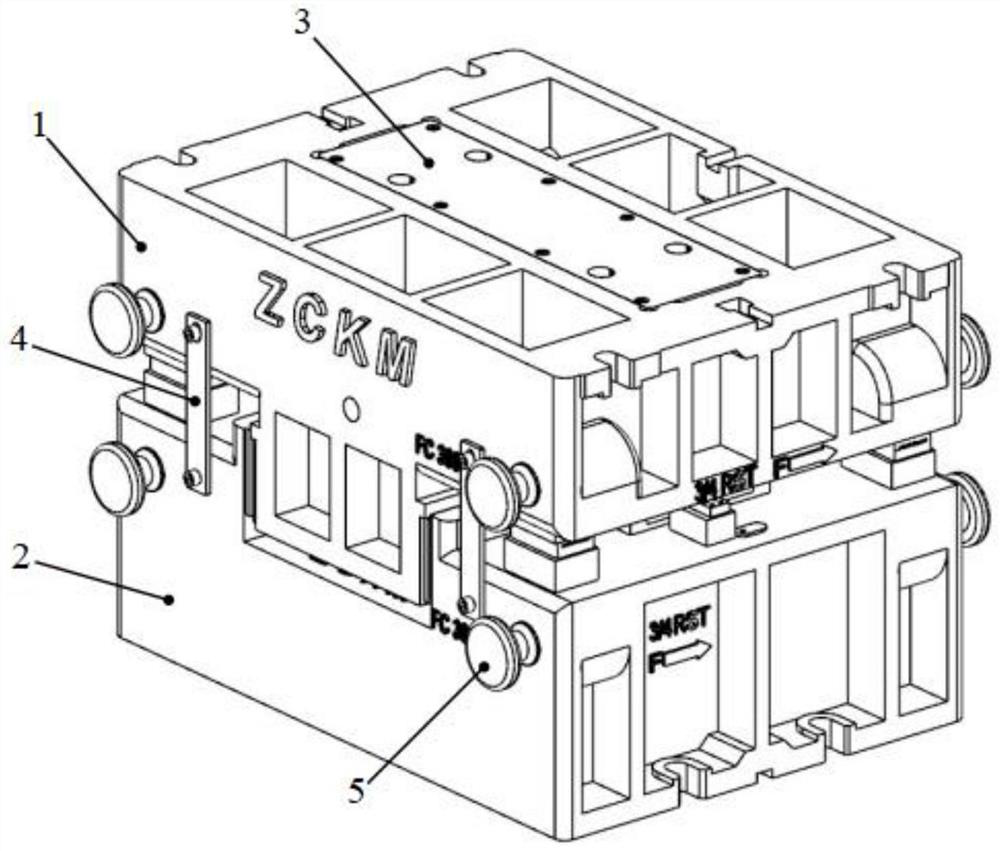

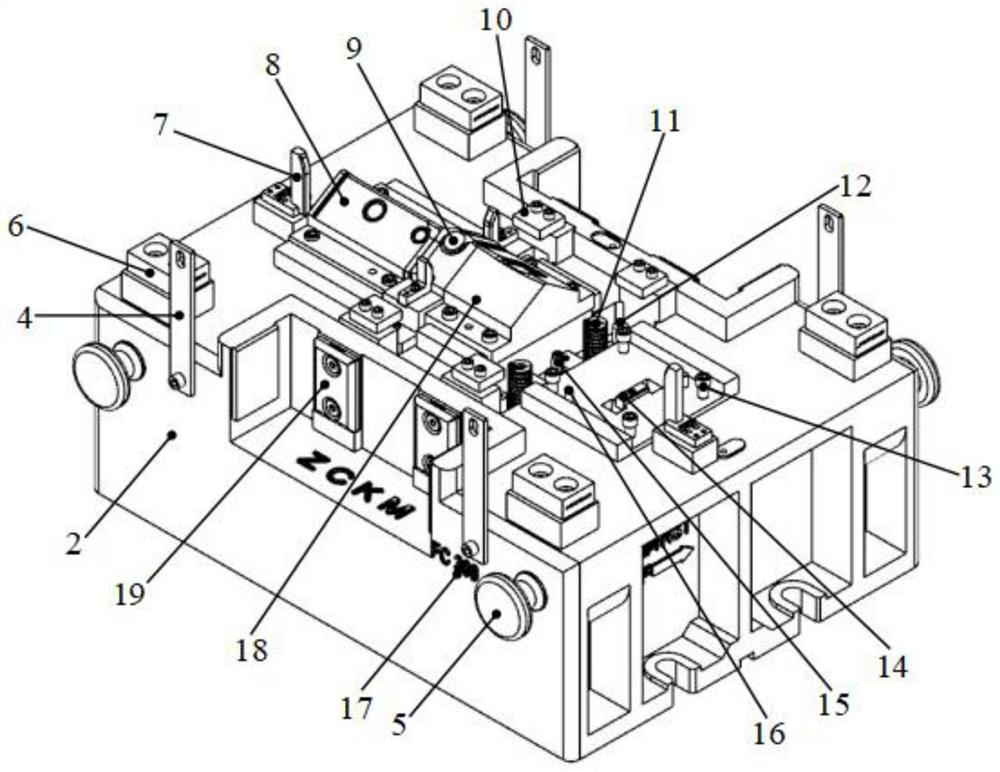

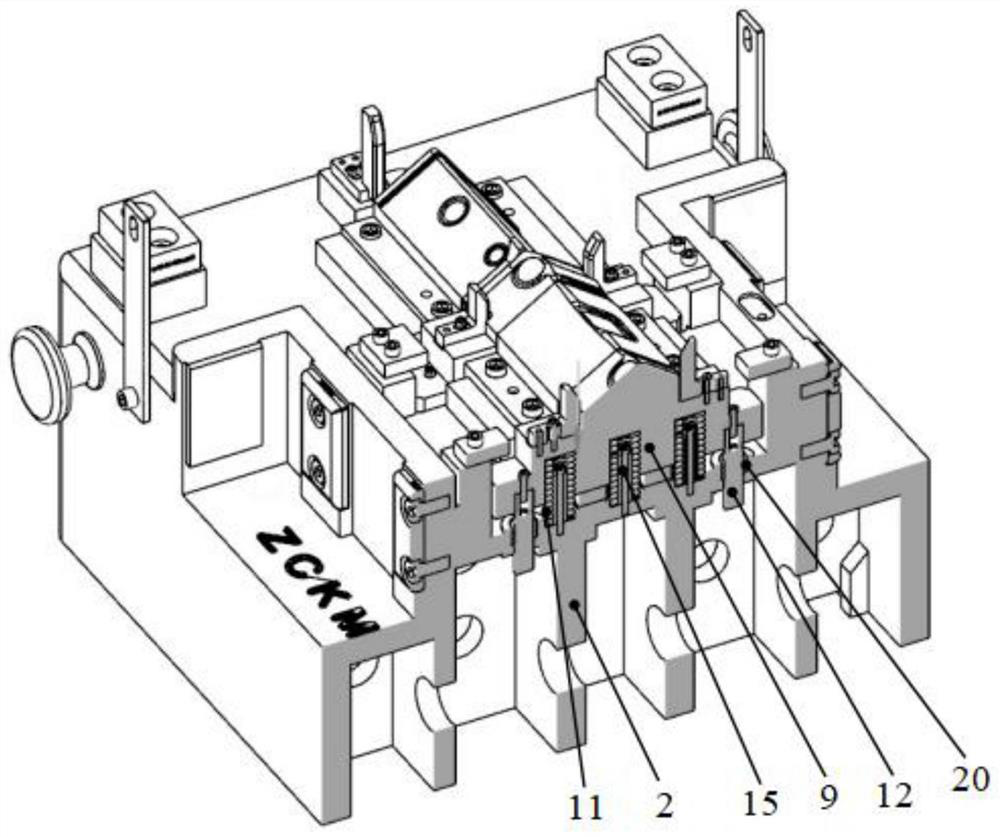

[0034] A plastic mold for automobile cover parts for teaching, characterized in that it includes an upper mold base 1 and a lower mold base 2, and the lower mold base 2 is provided with a connecting template 4, a limit block 6, a sheet metal positioner 7, a second A plastic punch insert 8, a second plastic punch insert 18, a top piece punch insert 9, a limit stopper 10, a rectangular spring 11, a top piece punch guide post 12, a screw nut assembly 13, and a positioning key 14. Spring fixing pin 15, cylindrical pin 16, guide plate 19 and guide sleeve 20; the upper mold base 1 is provided with a pressing core backing plate 3, a rectangular spring 11, a screw and nut assembly 13, a spring fixing pin 15, and a cylindrical pin 16. Guide plate 19, pressing core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com