Monitoring equipment for forest fire protection

A technology for monitoring equipment and forest fires. It is applied in the direction of mechanical equipment, cutting equipment, gardening tools/equipment, etc. It can solve problems such as stuck wind blades, difficult cleaning, and low work efficiency of staff, so as to ensure heat dissipation efficiency and prolong Endurance, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

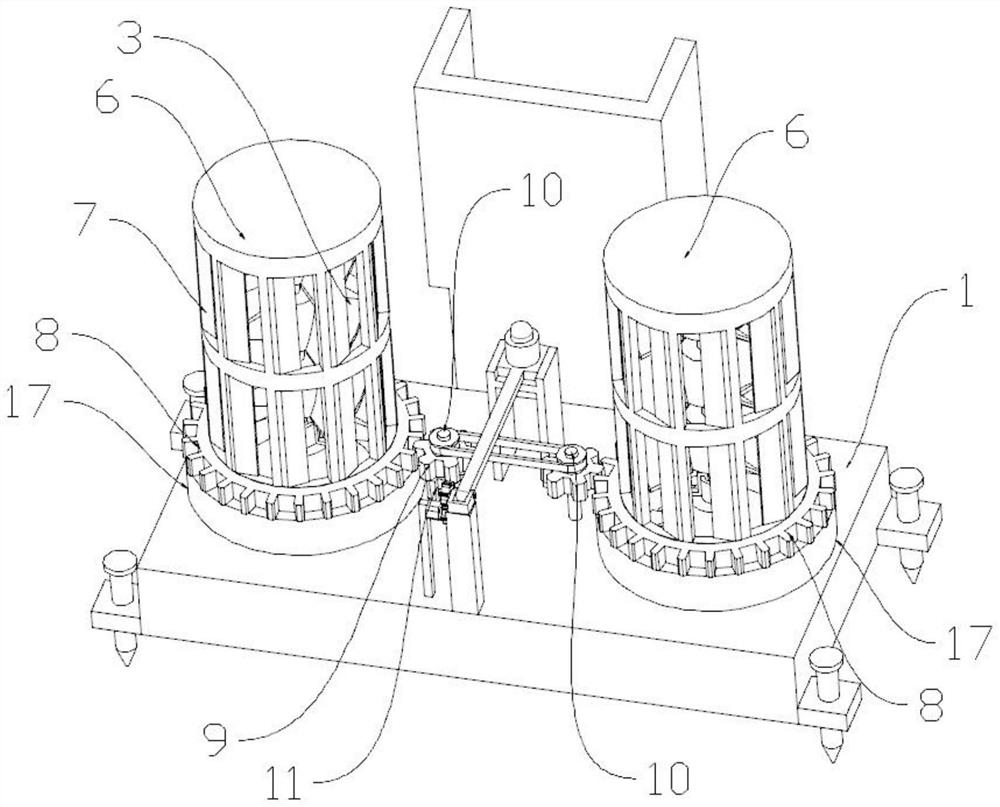

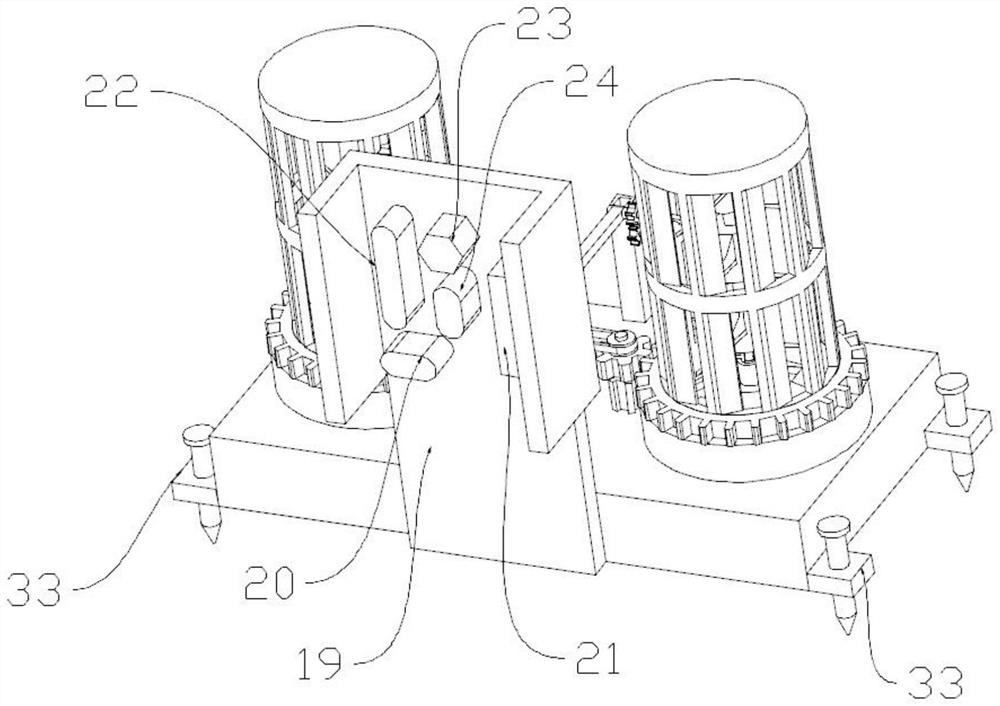

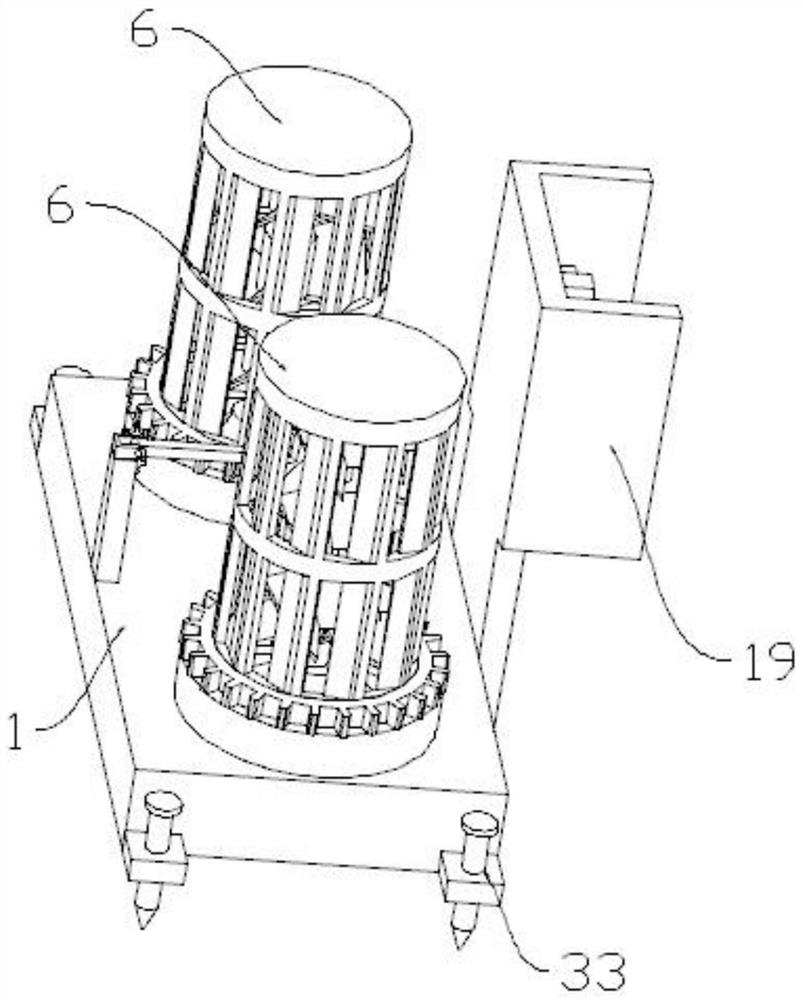

[0030] Depend on Figure 1-7 Given, the present invention includes a collection box 1, a wind shaft 2, and a wind generator 4. There are a plurality of wind shafts 2, a sleeve is installed on the wind shaft 2, and a wind blade 3 is installed on the sleeve, and the wind shaft 2 is connected to the wind power The generator 4 and the wind generator 4 are installed in the shell 5, and the outside of each wind shaft 2 is covered with a frame 6, and the frame 6 is provided with several through holes, and a cutting knife 7 is installed in the through hole, and the frame 6 The first gear 8 is installed, the first gear 8 is connected to the second gear 9, the transmission shaft 10 is interspersed in the second gear 9, and the transmission shaft 10 is connected to the cutting motor 11;

[0031] A cleaning motor 12 is installed in the casing 5, and a third gear 13 is installed on the cleaning motor 12. The third gear 13 is connected to the fourth gear 14 through tooth meshing, and the fo...

Embodiment 2

[0034] On the basis of Embodiment 1, an adjusting block 25 is installed on the collection box 1, and an adjusting plate 26 is installed in the adjusting block 25, and a camera bracket is installed on the adjusting plate 26, and a camera 27 is installed on the camera bracket, and the camera 27 has a 360 ° photography function, the collection box 1 is provided with a support frame 28 at the lowest position corresponding to the camera 27, the adjustment plate 26 can be stuck in the support frame 28, the adjustment plate 26 is connected to the rotation shaft, and the first direction adjustment gear 29 is set on the outer side of the rotation shaft , the first direction adjustment gear 29 is connected to the second direction adjustment gear 30, the second direction adjustment gear 30 is installed on the adjustment motor 31, the adjustment motor 31 is installed on the motor support 32, and the motor support 32 is installed on the collection box 1.

Embodiment 3

[0036] The present invention includes a collection box 1, a wind shaft 2, and a wind generator 4. There are multiple wind shafts 2, a sleeve is installed on the wind shaft 2, and a wind blade 3 is installed on the sleeve, and the wind shaft 2 is connected to the wind generator 4. , the wind generator 4 is installed in the shell 5, and the outside of each wind shaft 2 is covered with a frame 6, and the frame 6 is provided with several through holes, and a cutting knife 7 is installed in the through hole, and the frame 6 is equipped with a second A gear 8, the first gear 8 is connected to the second gear 9, the second gear 9 is interspersed with a transmission shaft 10, the transmission shaft 10 is connected to the cutting motor 11, a transmission wheel is installed on each transmission shaft 10, and a transmission belt is installed on the transmission wheel , a plurality of transmission shafts 10 are connected by transmission wheels and transmission belts; a frame 6 and a cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com