Pick-and-place structure, die bonding equipment and working method of die bonding equipment

A technology of solid crystal and worktable, which is applied in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., can solve problems such as low production efficiency, and achieve the effect of improving production efficiency, improving work quality, and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

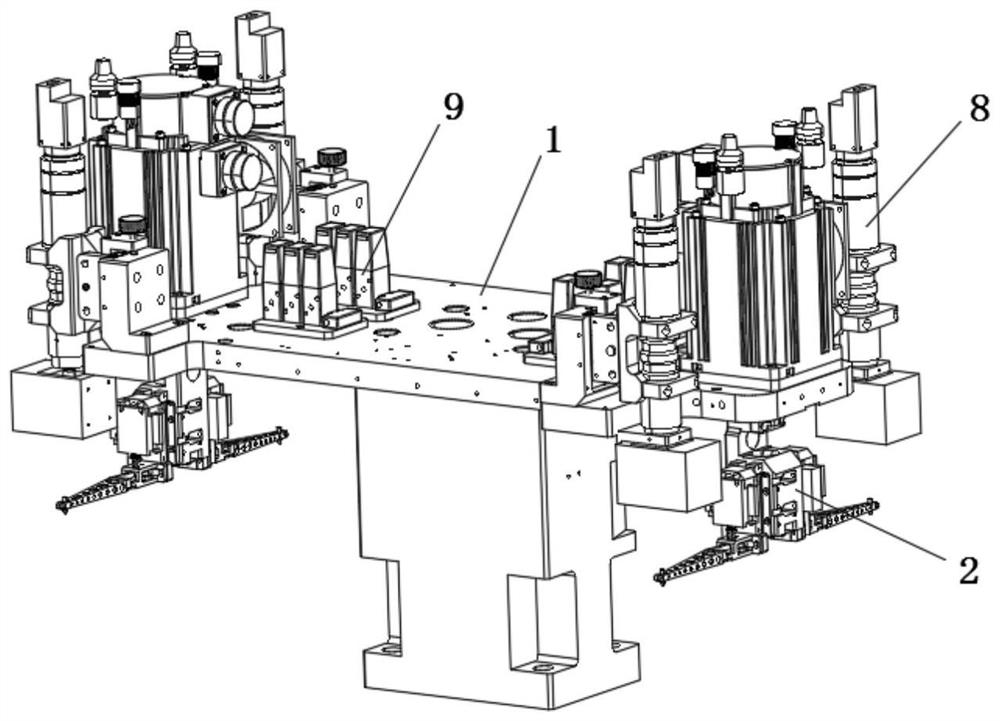

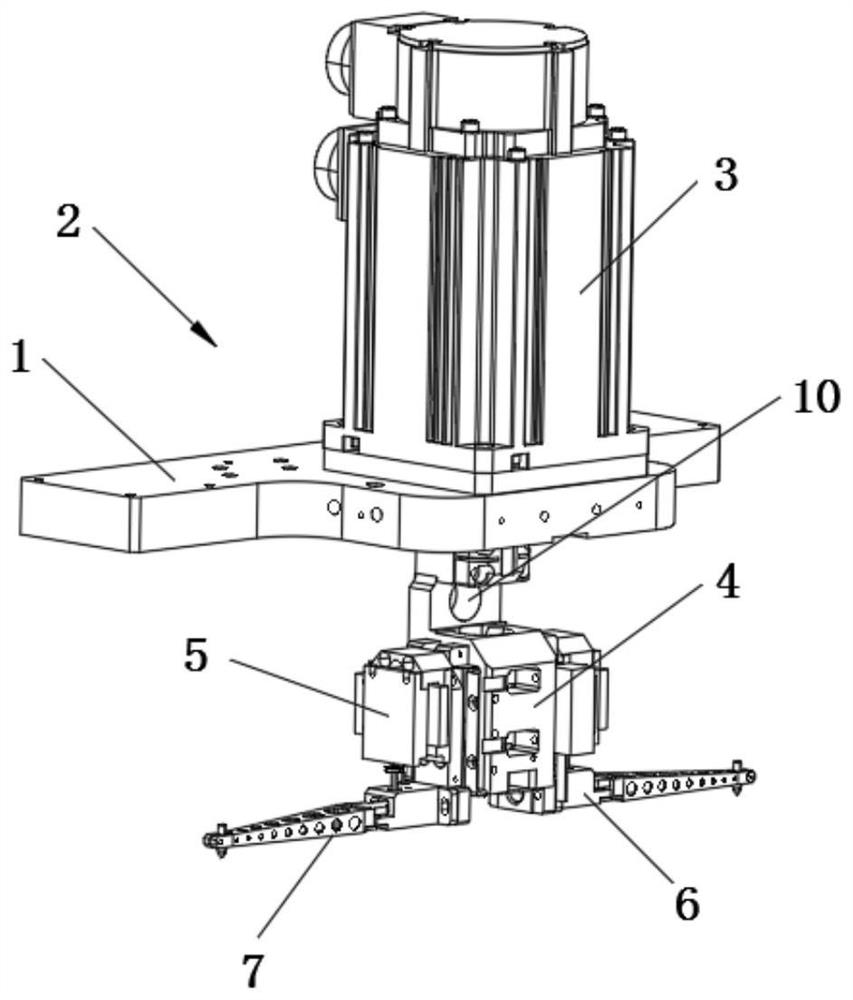

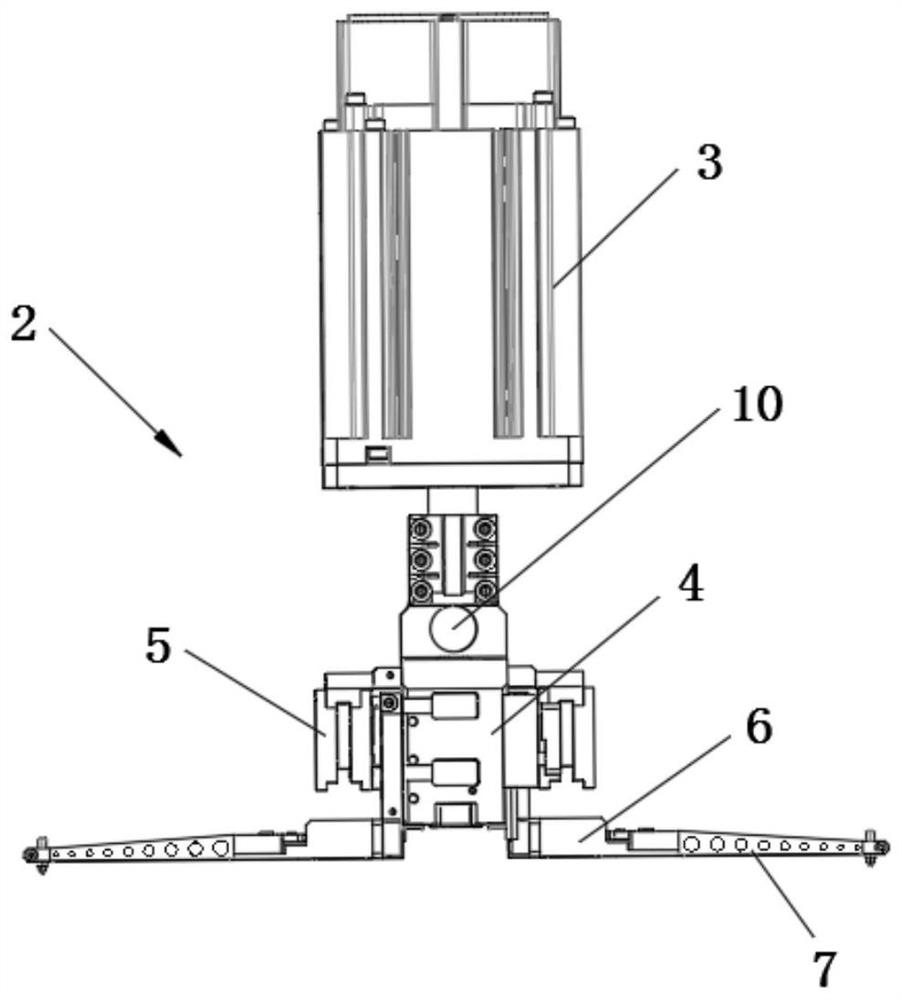

[0033] Example: as Figure 1-3 As shown in the figure, a pick-and-place structure and crystal-bonding equipment of the present invention includes a workbench 1, and two ends of the workbench 1 are symmetrically provided with a pick-and-place crystal-fixing mechanism 2. The spindle rotating motor 3 and the mounting frame 4 arranged under the worktable 1, the output end of the spindle rotating motor 3 is inserted through the worktable 1 and connected to the mounting frame 4, the two sides of the mounting frame 4 are symmetrically provided with a voice coil motor 5, and the voice coil The output end of the motor 5 is provided with a mounting seat 6, and the mounting seat 6 is provided with a swing arm 7. The two voice coil motors 5 and the two swing arms 7 are symmetrically distributed on both sides of the lower part of the working platform 2 with the spindle rotating motor 3 as the axis. , By using the double swing arm 7 to move alternately, the time is shortened and the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com