High-strength and high-plasticity aluminum-based composite material and preparation process thereof

An aluminum-based composite material and high plasticity technology, applied in the field of aluminum-based composite materials, can solve the problems of high strength, low strength, and low plasticity, and achieve the effects of improving strength and plasticity, uniform distribution, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

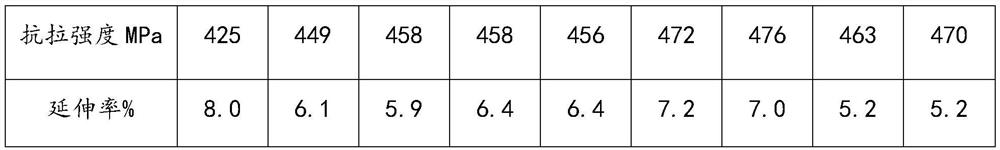

Embodiment 1

[0038] The high-strength and high-plastic aluminum-based composite material of this embodiment is composed of an aluminum alloy matrix and a reinforcing material, and the reinforcing material is composed of zirconium dioxide and titanium diboride.

[0039] Among them, in terms of the mass percentage of the aluminum matrix composite material, it includes: 4.7% of zirconium dioxide, 3.3% of titanium diboride, and the balance is the aluminum alloy base material;

[0040] In terms of mass percentage of the aluminum alloy substrate, it contains: 0.16% silicon, 0.78% magnesium, 0.45% manganese, 0.12% zinc, 0.24% tantalum, 0.33% vanadium, and the balance is aluminum.

Embodiment 2

[0042] The high-strength and high-plastic aluminum-based composite material of this embodiment is composed of an aluminum alloy matrix and a reinforcing material, and the reinforcing material is composed of zirconium dioxide and titanium diboride.

[0043] Among them, in terms of the mass percentage of the aluminum-based composite material, it includes: 5.1% of zirconium dioxide, 4.4% of titanium diboride, and the balance is the aluminum alloy base material;

[0044] In terms of mass percentage of the aluminum alloy substrate, it contains: 0.20% silicon, 0.94% magnesium, 0.55% manganese, 0.15% zinc, 0.27% tantalum, 0.37% vanadium, and the balance is aluminum.

Embodiment 3

[0046] The high-strength and high-plastic aluminum-based composite material of this embodiment is composed of an aluminum alloy matrix and a reinforcing material, and the reinforcing material is composed of zirconium dioxide and titanium diboride.

[0047] Among them, in terms of the mass percentage of the aluminum-based composite material, it includes: 6.2% of zirconium dioxide, 5.8% of titanium diboride, and the balance is the aluminum alloy base material;

[0048] In terms of mass percentage of the aluminum alloy substrate, it contains: 0.24% silicon, 1.16% magnesium, 0.65% manganese, 0.18% zinc, 0.30% tantalum, 0.41% vanadium, and the balance is aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com