Ground surface putty scraping device for house building

A scraping device and putty technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of affecting work efficiency and inconvenient collection of putty, so as to achieve the effect of convenient collection and avoiding the accumulation and falling of putty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

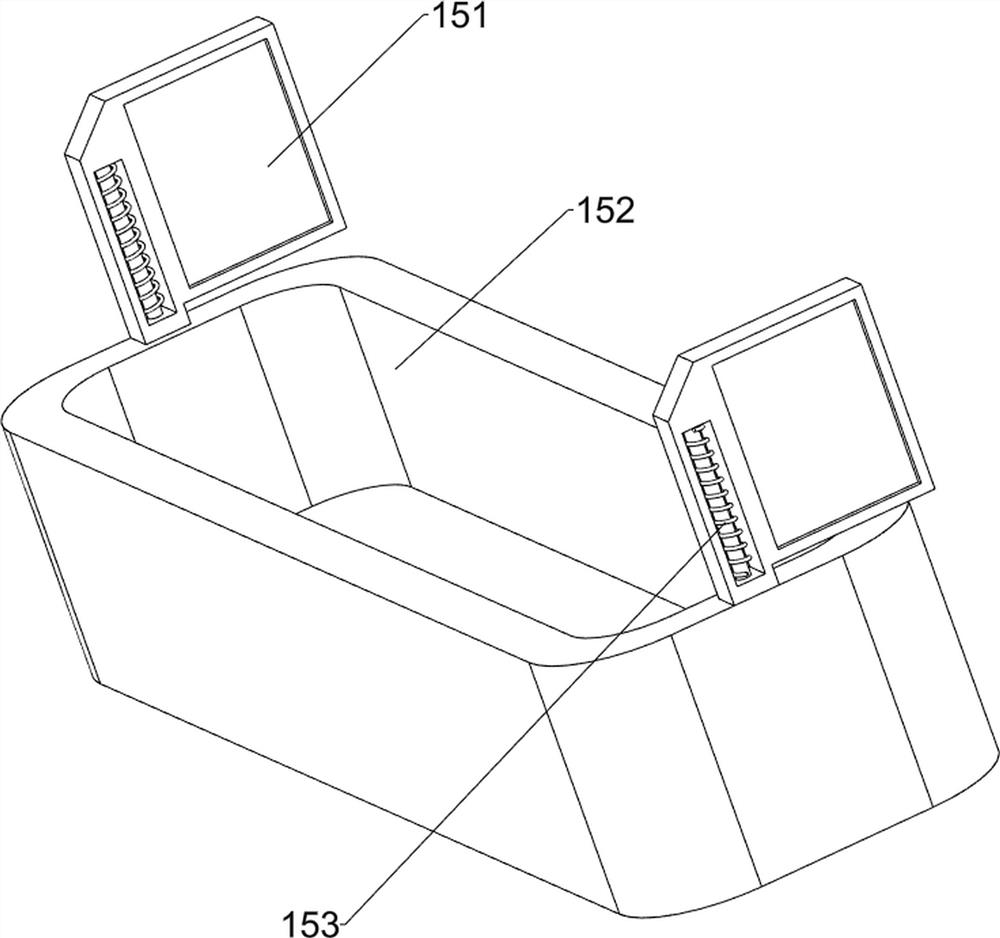

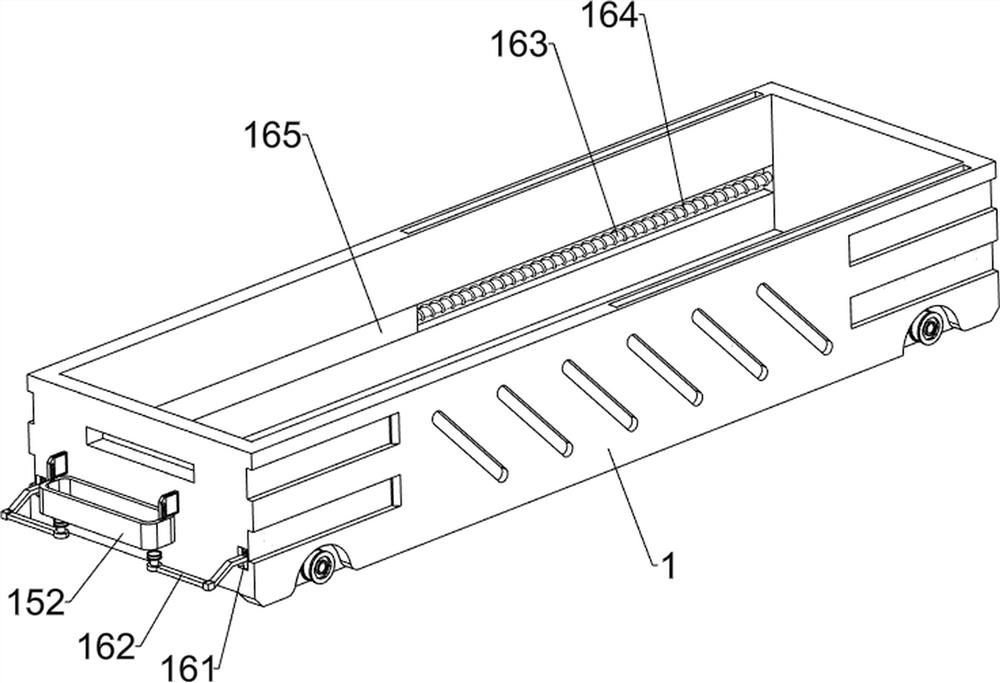

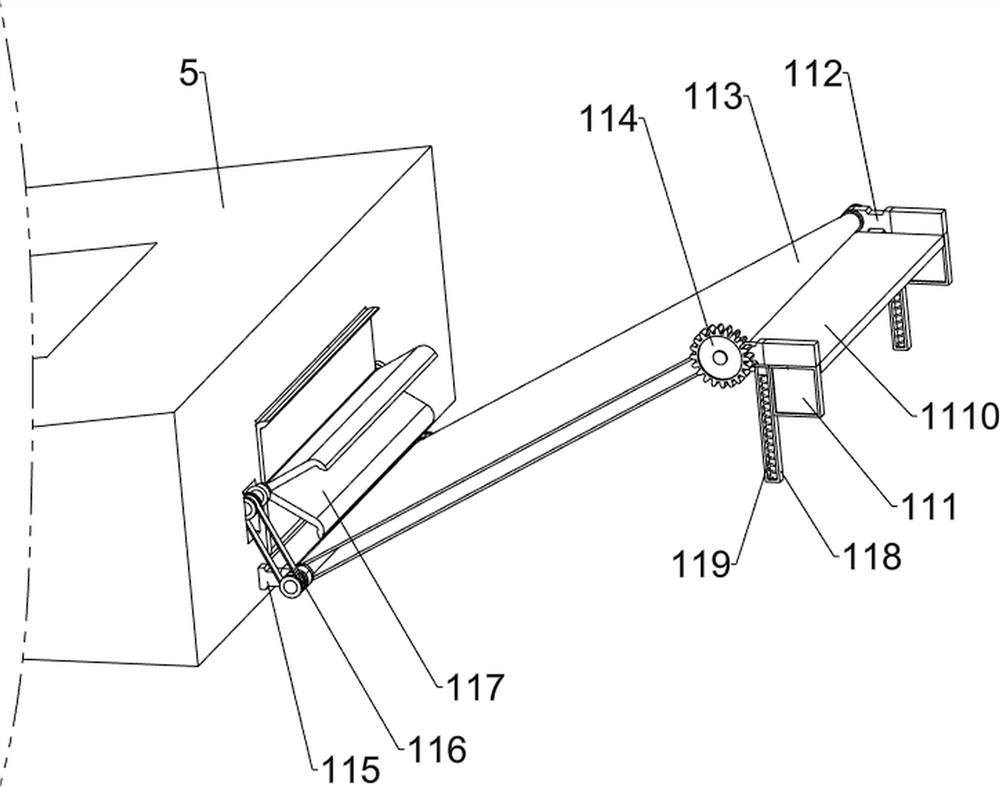

[0037] see Figure 1-Figure 6, a ground putty scraping device for housing construction, including a storage box 1, a handle 2, a first connecting rod 3, a roller 4, a shovel plate 5, a conveying mechanism 11 and a driving mechanism 12, the right side of the storage box 1 is provided with The grip 2, the left side of the storage box 1 is provided with a first connecting rod 3 symmetrically in front and back, the left and right sides of the lower part of the storage box 1 are provided with rollers 4 in a front and rear symmetrical rotation, and a shovel plate is provided between the left ends of the two first connecting rods 3 5. The shovel plate 5 can scrape the putty. The storage box 1 and the shovel plate 5 are provided with a conveying mechanism 11, which can transport the scraped putty. The storage box 1 is provided with a driving mechanism 12. The driving mechanism 12 A power source can be provided for the conveying mechanism 11 .

[0038] see Figure 4-Figure 5 , the co...

Embodiment 2

[0042] see figure 1 , figure 2 , Figure 7 and Figure 8 , On the basis of Embodiment 1, it also includes a scraping mechanism 13, which can scrape the stubborn putty, and the scraping mechanism 13 includes a fourth mounting plate 131, a scraping plate 132, a first The pressing rod 133, the first guide rod 134 and the second compression spring 135, the fourth mounting plate 131 is welded on the front and rear sides of the right part of the shovel plate 5, and the two fourth mounting plates 131 are slidably provided with first guide rods 134. Scraping plates 132 are provided on the two first guide rods 134. The scraping plates 132 can scrape the stubborn putty. The middle of the scraping plates 132 is symmetrically arranged with a first pressure rod 133. A second compression spring 135 is wound between the left sides of the two fourth mounting plates 131 .

[0043] see figure 1 , figure 2 , Figure 9 and Figure 10 , also includes a compaction mechanism 14, the compac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com