Automobile A column side column collision test device

A test device and automobile technology, applied in the direction of measuring device, using one-time impact force test material strength, impact test, etc., can solve the long preparation period, increase the development cycle, and it is difficult to accurately reflect the deformation of the vehicle's side column impact and side wall and other problems, to achieve the effect of reducing test cost, ensuring test accuracy, convenient deformation and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

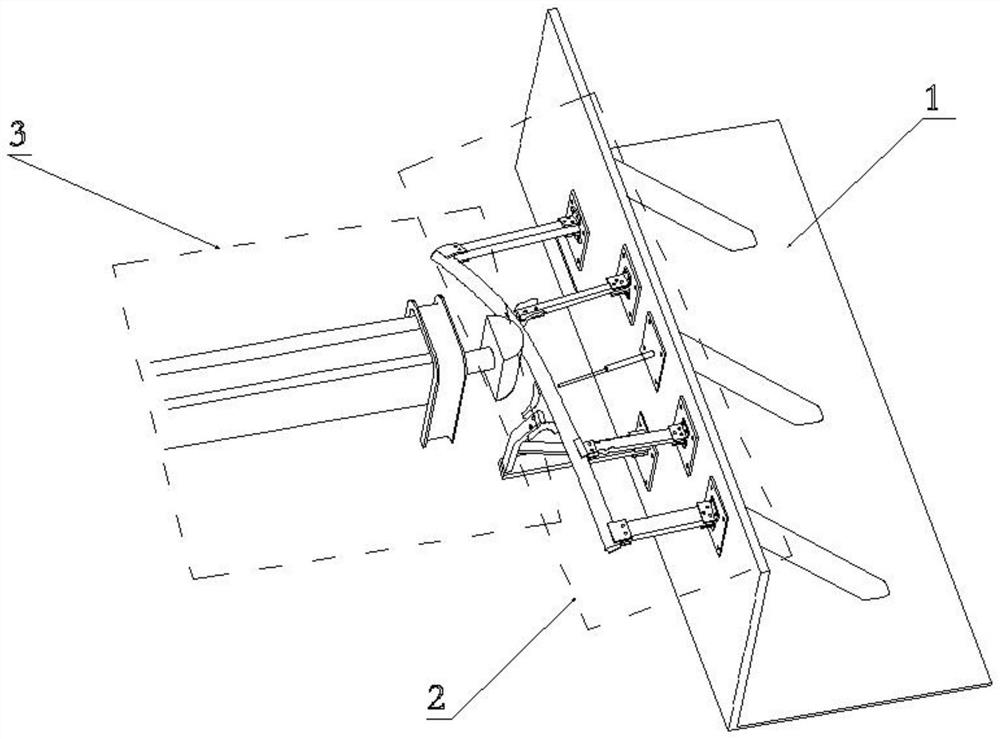

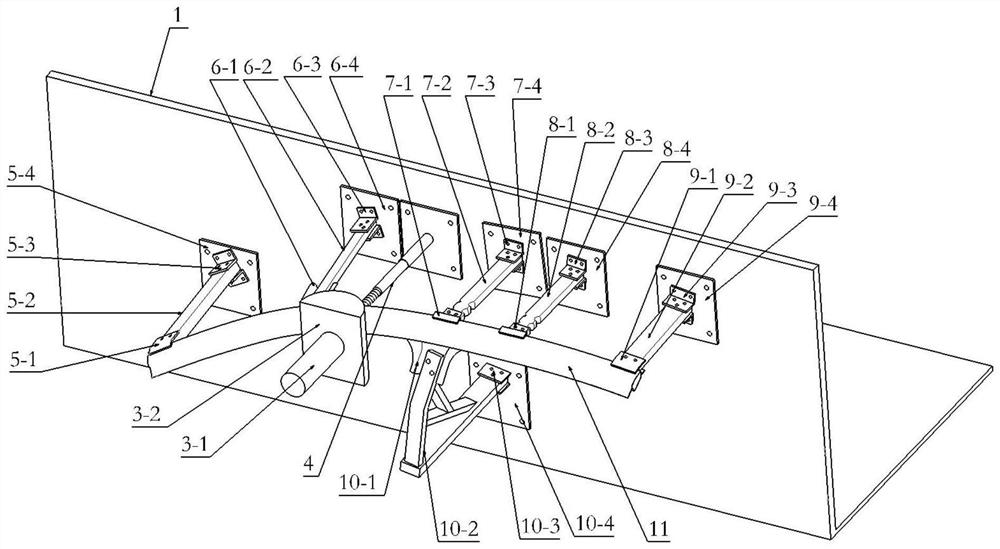

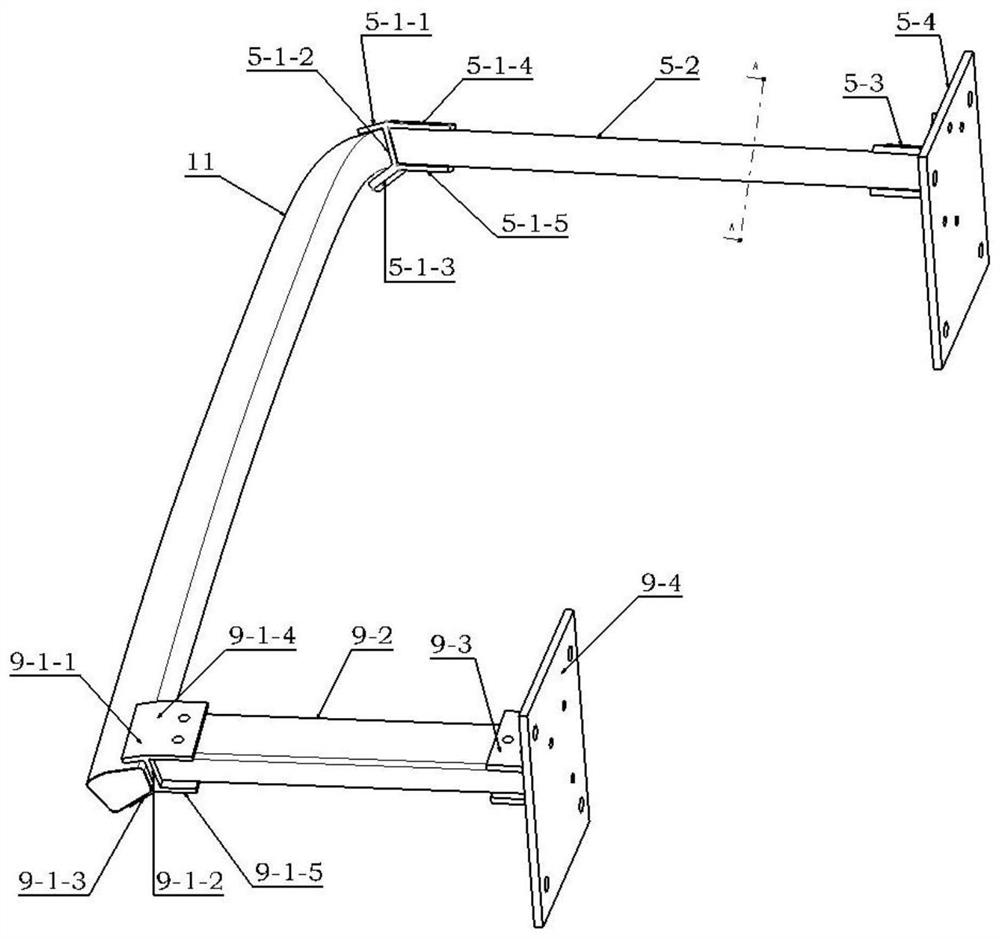

[0037] refer to Figure 1-2 , an automobile A-pillar side column impact test device, comprising impact equipment 3, A-pillar holding tooling 2 and test installation fixing bench 1; A-pillar holding tooling 2 is connected with the test installation fixing bench 1, A-pillar 11 passes through A The column support tool 2 is connected to the test installation and fixed bench 1. The test installation and fixed bench 1 is fixed on the ground or a flat table. The impact equipment 3 is connected with a pneumatic or motor traction device, and the impact equipment 3 drives the impact head through pneumatic or motor traction. The A-pillar 11 is hit at a certain speed, and the impact position is the contact position of the side column of the vehicle. The impact device 3 includes an impact head 3-2. The rear end of the impact head 3-2 is provided with a sensor 3-1, and the rear of the A-pillar 11 is provided with a Displacement sensor 4, the other end of the displacement sensor 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com