Glass bottle inspection machine

An inspection machine and glass bottle technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as reduced inspection efficiency, glass bottle damage, inspection line stoppage, etc., to achieve enhanced inspection results, a wide range of applications, and stable clamping performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

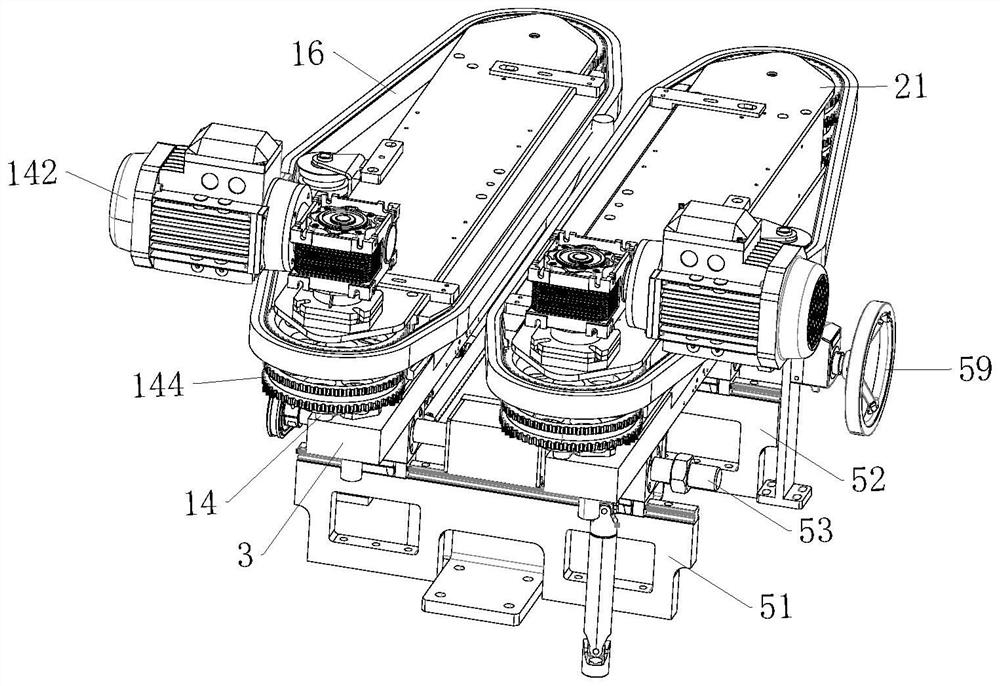

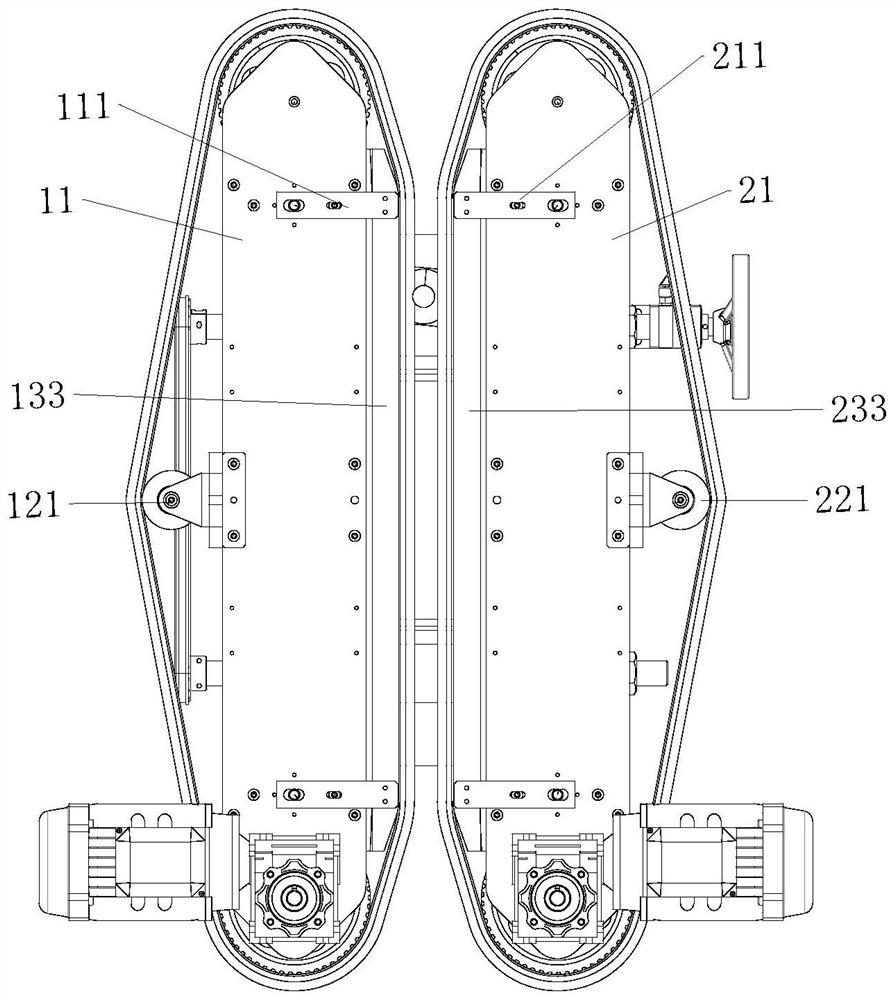

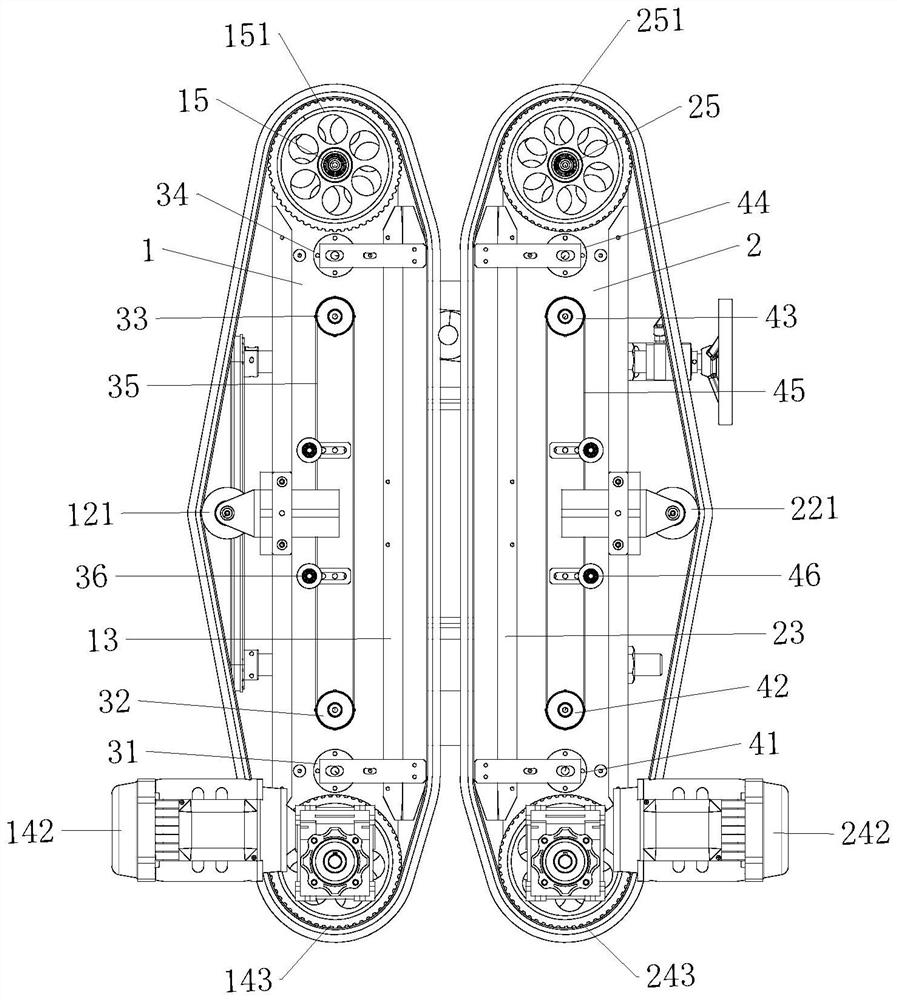

[0025] refer to Figure 1 to Figure 7 , A glass bottle inspection machine, comprising a clamping module, the inspection machine is sequentially provided with a light source module, a distance adjustment module, a height adjustment module and the clamping module from bottom to top, the clamping The module includes a left clamping module and a right clamping module that are symmetrically arranged, and the left clamping module includes a left bottom fixing plate 1 and a left upper layer module and a left lower layer module fixed on the left bottom fixing plate 1 , the right clamping module includes a right bottom surface fixing plate 2 and a right upper layer module and a right lower layer module fixed on the right bottom surface fixing plate 2 .

[0026] In this application, glass bottles are clamped and rubbed by symmetrically arranged left clamping module and right clamping module. In addition, this application is provided with a left upper layer module, a left lower layer mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com