Square inner cavity nozzle with noise reduction function

A square, inner cavity technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of increasing cost, complicated nozzle structure, limiting the use range of nozzles, etc., and achieve the effect of reducing noise and making small changes in manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific implementations.

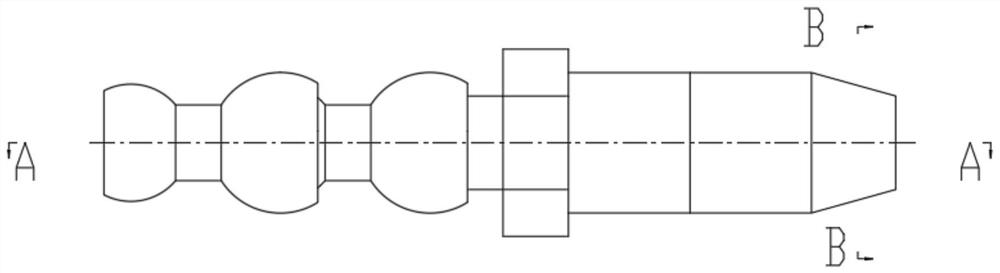

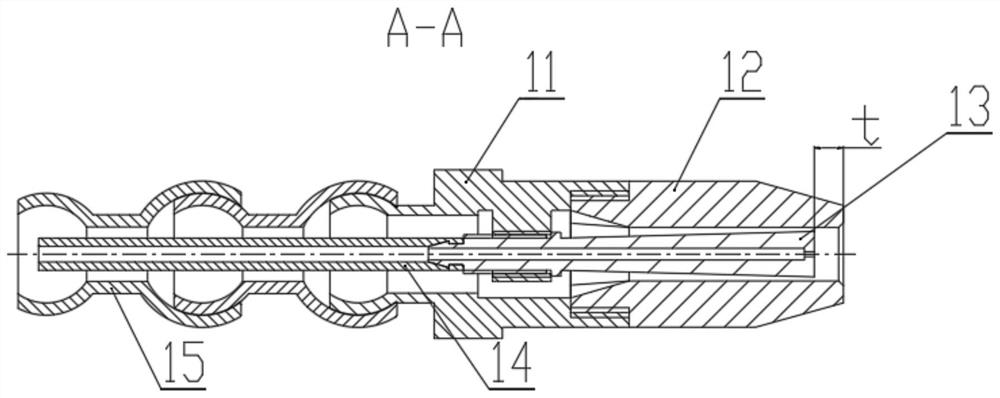

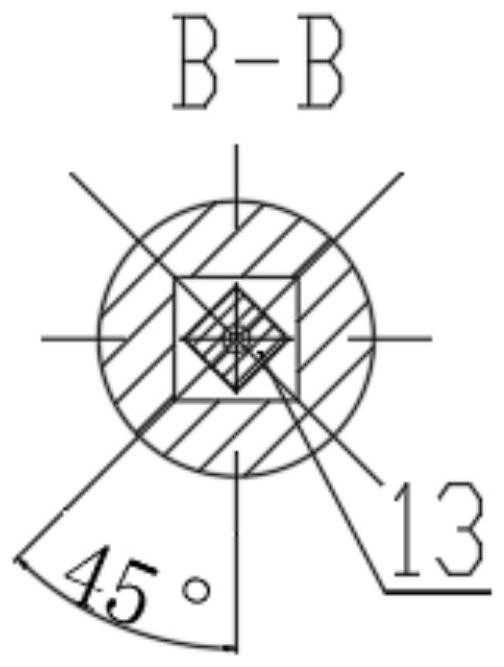

[0037] like Figure 1-Figure 3 Shown are the structural schematic diagram and cross-sectional view of the noise reduction nozzle. Its structure includes a base 11, a nozzle head 12, a nozzle core 13, a bamboo tube 14 and an infusion hose 15; and the nozzle head 12 is provided with a coaxial cavity arranged through the axial direction, the nozzle core 13 is installed in the inner cavity of the base 11 and the nozzle head 12, and the rear end of the nozzle core 13 is connected with the fluid source through the infusion hose 15 , the infusion hose 15 is arranged through the bamboo tube 14, and the front end of the nozzle core 13 faces the front end of the nozzle head 12; The squares of 12 and nozzle core 13 are arranged offset by 45 degrees.

[0038] An axial injection channel is provided inside the nozzle core 13 , and the injection channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com